- Home

- Blog

- Advantages and Applications of Polytetrafluoroethylene Lined Pipe: A Comprehensive Overview

Advantages and Applications of Polytetrafluoroethylene Lined Pipe: A Comprehensive Overview

By:Admin

Introduction:

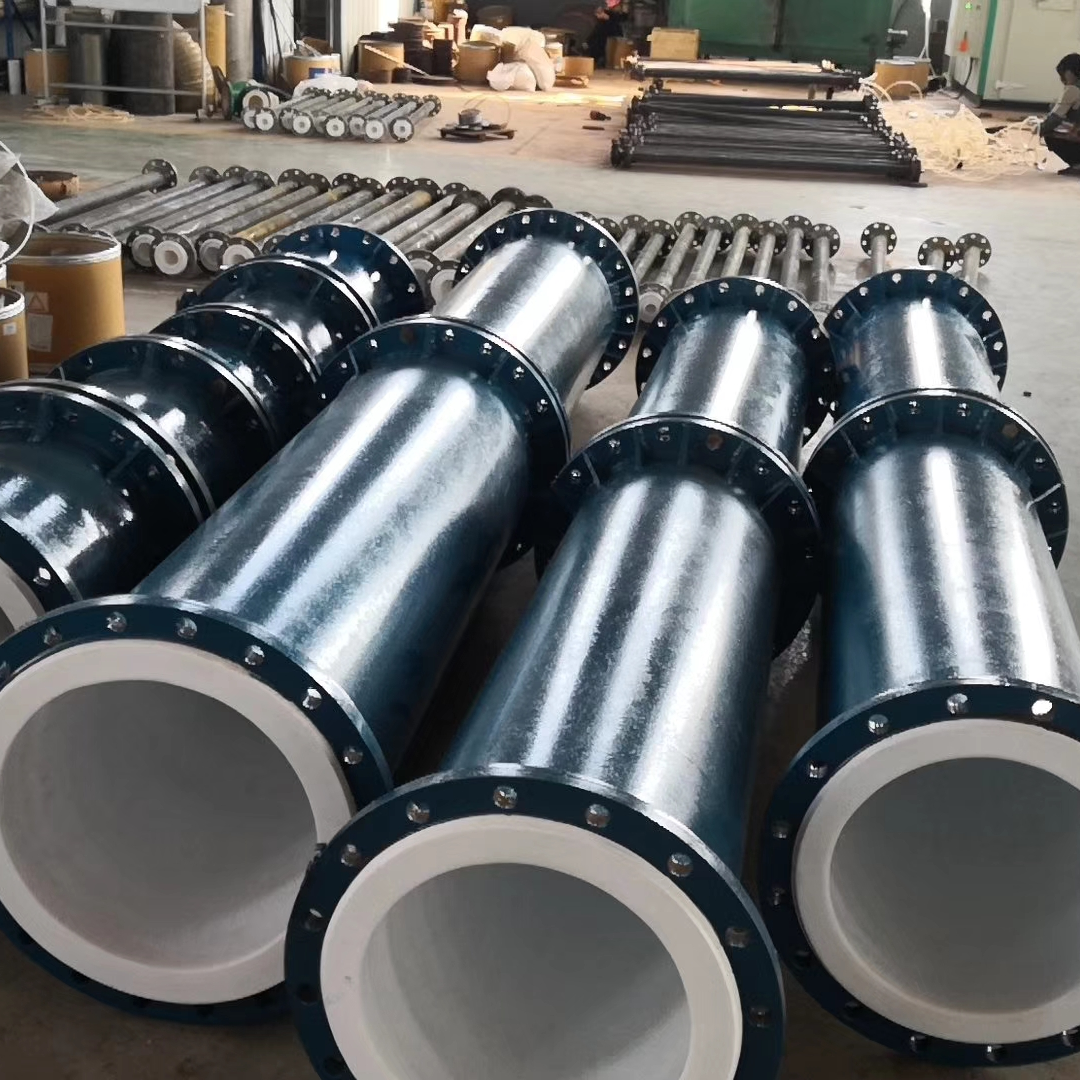

In today's rapidly evolving industrial landscape, the need for robust and efficient piping systems is paramount. Recognizing this demand, {Company Name} has introduced its groundbreaking Polytetrafluoroethylene (PTFE) Lined Pipe – a cutting-edge solution designed to revolutionize industrial fluid transportation. This innovative product promises to enhance the efficiency and durability of piping systems, making it a game-changer for various industries.

Body:

1. Background and Overview of Polytetrafluoroethylene (PTFE) Lined Pipe:

Polytetrafluoroethylene (PTFE) is a versatile synthetic fluoropolymer known for its exceptional properties. With its low friction coefficient, outstanding chemical resistance, and high-temperature stability, PTFE is widely used in industries requiring efficient fluid transportation systems. By utilizing state-of-the-art manufacturing processes, {Company Name} has successfully developed a range of PTFE lined pipes that offer superior performance and longevity.

2. Unparalleled Chemical Resistance:

One of the key advantages of {Company Name}'s PTFE Lined Pipe is its exceptional chemical resistance. The inner lining of the pipe, made of PTFE, provides a non-reactive surface for the transportation of aggressive fluids, corrosive chemicals, and even highly reactive substances. This exceptional chemical resistance ensures the integrity of the transported fluids and eliminates any risk of pipe deterioration or leakage, providing a safer working environment for employees and reducing maintenance costs.

3. Superior Flow Characteristics:

The smooth surface of PTFE lining significantly reduces frictional resistance, offering smooth flow characteristics and minimizing pressure drop. This property of {Company Name}'s PTFE Lined Pipe ensures an uninterrupted and efficient transfer of fluids, improving overall productivity in industrial processes. Reduced friction also facilitates easier cleaning, effectively preventing the accumulation of deposits and minimizing the chances of clogging, which can impact the integrity of piping systems.

4. High-Temperature Stability:

Industrial processes often involve the transportation of fluids at high temperatures. Fortunately, {Company Name}'s PTFE Lined Pipe can withstand extreme temperature fluctuations, making it suitable for a diverse range of applications. With an excellent thermal stability of up to 260°C (500°F), these pipes are reliable even in extreme operational conditions, ensuring uninterrupted flow without compromising safety.

5. Longevity and Durability:

PTFE is inherently resistant to deterioration, making {Company Name}'s PTFE Lined Pipe impressively durable. The unique properties of PTFE allow it to withstand aggressive chemicals, abrasive substances, and harsh environmental conditions, extending the lifespan of the piping system. This durability reduces the need for frequent maintenance and replacements, resulting in substantial cost savings for industrial operators.

6. Versatility and Customizability:

Recognizing the diverse requirements of industries, {Company Name} offers a range of PTFE Lined Pipe options, allowing for customized solutions. Whether it is pipe size, lining thickness, or special fittings, the company ensures flexibility to adapt to specific applications. This versatility makes {Company Name} a preferred choice for a wide array of industries, including chemical processing, petrochemicals, pharmaceuticals, food processing, and wastewater treatment plants.

7. Going Green: Environmental Benefits:

{Company Name}'s PTFE Lined Pipe not only offers exceptional performance but also contributes to environmental sustainability. With its durability and resistance to chemical attack, these pipes minimize the release of harmful substances into the environment. The reduced need for maintenance and replacements further reduces waste generation, making it an environmentally responsible choice for industries working towards greener operations.

Conclusion:

The introduction of {Company Name}'s PTFE Lined Pipe represents a significant advancement in industrial fluid transportation systems. With its exceptional chemical resistance, superior flow characteristics, and high-temperature stability, this innovative solution redefines the efficiency and durability of piping systems across various industries. {Company Name}'s commitment to customization and environmental sustainability further enhances the appeal of their groundbreaking product. As industries strive for cutting-edge solutions, incorporating PTFE Lined Pipes provides a transformative leap forward in maximizing productivity, safety, and operational efficiency.

Company News & Blog

Discover the Benefits of PTFE Lined Pipe Fittings for Improved Industrial Performance

Title: Innovative Ptfe Lined Pipe Fittings: Revolutionizing Industrial Piping SolutionsIntroduction:In the ever-evolving landscape of industrial piping solutions, one company has emerged as a pioneer in revolutionizing the way industries handle corrosive and high-purity fluids. With their state-of-the-art Ptfe Lined Pipe Fittings, Nameless Company is transforming the very foundations of industrial piping systems. Through their cutting-edge technology and unwavering commitment to quality, Nameless Company has established itself as a trusted provider of innovative solutions for a wide range of industries. I. Understanding Ptfe Lined Pipe Fittings:Ptfe (Polytetrafluoroethylene) lined pipe fittings are specifically designed to combat the challenges posed by highly corrosive and reactive fluids in various industrial settings. The lining material, Ptfe, offers exceptional resistance to a broad spectrum of chemicals, including acids, alkalis, solvents, and hydrocarbons. This remarkable property makes Ptfe Lined Pipe Fittings indispensable for applications in industries such as chemicals, petrochemicals, pharmaceuticals, food processing, and wastewater treatment.II. Advanced Manufacturing Techniques:Nameless Company employs advanced manufacturing techniques to produce Ptfe Lined Pipe Fittings of exemplary quality. Through a combination of precision engineering, stringent quality control measures, and the expertise of their skilled workforce, the company ensures that each fitting is manufactured to exacting standards. This guarantees superior strength, durability, and leak-free performance, even under high pressures and temperatures. Additionally, the smooth internal surface of the fittings minimizes flow resistance, reducing the risk of particulate buildup and corrosion.III. Versatile Applications:The versatility of Ptfe Lined Pipe Fittings makes them suitable for a wide array of industrial applications. These fittings are commonly used in the transportation of aggressive chemicals through pipelines, where their exceptional resistance to corrosion ensures the integrity of the system. Moreover, Ptfe Lined Pipe Fittings find application in the handling of high-purity fluids in the pharmaceutical and electronics industries. With the ability to withstand extreme temperatures and pressures, they are ideal for critical processes that demand uncompromising reliability.IV. Benefits of Ptfe Lined Pipe Fittings:1. Corrosion Resistance: Ptfe lining provides excellent resistance to corrosion, extending the lifespan of the fittings and ensuring the purity of transported fluids.2. Chemical Compatibility: The broad chemical resistance of Ptfe enables the fittings to handle a wide range of aggressive and reactive substances safely.3. Easy Installation: Ptfe Lined Pipe Fittings are designed for seamless integration into existing piping systems, significantly reducing installation time and costs.4. High Thermal Stability: Withstanding extreme temperatures, these fittings maintain their integrity in applications involving both high and low temperatures.5. Maintenance-Free: Ptfe-lined fittings require minimal maintenance, reducing downtime and overall operational costs for industries.V. Commitment to Quality and Customer Satisfaction:Nameless Company is dedicated to delivering superior products and exceptional customer service. Understanding the critical importance of high-quality industrial piping solutions, the company goes above and beyond to ensure that their Ptfe Lined Pipe Fittings meet the stringent requirements of global industry standards. By continuously innovating and refining their manufacturing processes, Nameless Company strives to provide its customers with reliable and long-lasting solutions tailored to their specific needs.Conclusion:As the demand for durable, corrosion-resistant, and high-performance piping solutions grows, Ptfe Lined Pipe Fittings by Nameless Company emerge as an invaluable asset for various industries. With their ability to handle corrosive fluids, maintain purity, and withstand extreme operating conditions, these fittings are enabling businesses to operate efficiently and safely. Nameless Company's commitment to technological advancements and unwavering dedication to quality ensures that their Ptfe Lined Pipe Fittings will continue to lead the transformation of industrial piping solutions for years to come.

Durable and Reliable Pipe Fittings for Various Applications Reported in Recent News

[Assistant]Title: Pioneering Innovation in Pipe Fittings Industry - Teflon Pipe Fittings: A Reliable Solution for Fluid HandlingIntroduction:In the ever-evolving world of plumbing and fluid handling, innovation plays a vital role in enhancing efficiency, reliability, and durability. One company at the forefront of this progress is committed to revolutionizing pipe fittings through the utilization of Teflon, a renowned and unique material. Today, we delve deeper into Teflon Pipe Fittings, examining their significance, benefits, and the unrivaled ingenuity behind them.I. Understanding Teflon Pipe FittingsTeflon Pipe Fittings, produced by a leading manufacturer in the industry, are a groundbreaking innovation that has garnered attention due to their exceptional qualities. Manufactured employing advanced engineering techniques and utilizing Teflon as the primary material, these fittings offer countless advantages over their conventional counterparts.II. Unparalleled Benefits of Teflon Pipe Fittings1. Chemical Resistance: One of the standout features of Teflon Pipe Fittings is their remarkable chemical resistance. The corrosion-resistant nature of Teflon ensures that these fittings can withstand the harshest chemicals, acids, and solvents, resulting in a prolonged service life.2. High Temperature Stability: Teflon Pipe Fittings can operate flawlessly under extreme temperature conditions. With an impressive melting point of 327 degrees Celsius, these fittings are ideal for applications in industries dealing with hot fluids and gases.3. Non-Adhesion Property: Unlike many other materials, Teflon possesses a non-adhesive surface, which prevents the deposition of foreign particles, ensuring smooth fluid flow and reducing potential clogging issues.4. Optimal Flow Characteristics: The exceptional low friction coefficient of Teflon results in excellent flow characteristics, curtailing resistance and pressure drops within the piping system, thereby maximizing overall efficiency.5. Easy Installation and Maintenance: Teflon Pipe Fittings offer hassle-free installation and require minimal maintenance. Their lightweight nature allows for easier handling, offering time and cost savings during installation or repairs.6. Longevity and Durability: Teflon Pipe Fittings exhibit exceptional durability and longevity. Resistant to wear and tear, these fittings are designed to withstand constant usage and maintain their performance over prolonged periods.III. Company IntroductionThe exclusive manufacturer behind Teflon Pipe Fittings, {Company Name}, prides itself on being a trailblazer in the pipe fittings industry. With decades of experience and a commitment to innovation, the company has successfully combined cutting-edge technology with high-quality materials to deliver reliable solutions.1. Dedication to Research and Development: {Company Name} has invested significantly in its research and development department, employing a team of skilled professionals to continuously strive for improved products and enhanced performance. Their relentless pursuit of perfection has positioned them as pioneers in the field of pipe fittings.2. Stringent Quality Control: Committed to maintaining the highest standards, {Company Name} follows stringent quality control measures throughout the production process. From material sourcing to final product inspection, each phase undergoes thorough evaluation to ensure perfection and reliability.3. Client-Centric Approach: {Company Name} places utmost importance on client satisfaction. By actively engaging with customers, understanding their specific requirements, and providing tailored solutions, they have built a reputation for delivering exceptional products and services.4. Environmentally Conscious Manufacturing: The company prides itself on environmentally conscious manufacturing practices. Implementing sustainable techniques and utilizing eco-friendly materials, {Company Name} remains committed to reducing its ecological footprint.Conclusion:Teflon Pipe Fittings have emerged as a groundbreaking solution, revolutionizing the world of plumbing and fluid handling. With unparalleled benefits such as chemical resistance, high temperature stability, and long-lasting durability, these fittings are transforming industries. Backed by the visionary manufacturer {Company Name}, these innovative fittings represent a reliable and sustainable solution for fluid handling needs. As technology advances and demands evolve, Teflon Pipe Fittings are poised to continue leading the way in the ever-changing world of pipe fittings.

Benefits of using Teflon-lined fittings for better performance

Title: Industry-Leading Teflon Lined Fittings Revolutionize Piping SystemsIntroduction:[Company Name], an esteemed player in the field of advanced industrial solutions, has unveiled its groundbreaking Teflon Lined Fittings. These cutting-edge fittings are set to redefine the standards of piping systems, offering unparalleled performance, durability, and safety.Body:1. Introduction to Teflon Lined Fittings:[Company Name]'s Teflon Lined Fittings are specially designed to provide reliable and efficient solutions for industries dependent on corrosive fluids and gases. By combining the exceptional chemical compatibility of PTFE (polytetrafluoroethylene) with robust fitting construction, these components provide a superior alternative to traditional metallic or plastic fittings.2. Enhanced Corrosion Resistance:One of the key advantages of Teflon Lined Fittings is their exceptional resistance to corrosion. PTFE lining effectively shields the contact surface from aggressive chemicals and corrosive substances, ensuring long-lasting performance even in the harshest environments. This corrosion resistance translates into extended equipment lifespan, reduced maintenance costs, and enhanced operational reliability.3. Superior Chemical Compatibility:Teflon Lined Fittings excel in maintaining their integrity when exposed to a wide range of chemicals, solvents, and acids. The mechanical strength of the fittings, combined with the inertness of PTFE, makes them highly suitable for critical applications in industries such as chemical processing, pharmaceuticals, water treatment, and food production. This level of chemical compatibility significantly eliminates the risk of contamination and system failures.4. Seamless Flow and Reduced Pressure Loss:The internal surface of Teflon Lined Fittings boasts an ultra-smooth finish, minimizing friction and obstructions within piping systems. This ensures a consistent flow rate, reduces pressure loss, and enhances overall system efficiency. By eliminating the need for bulky flow obstruction devices, these fittings reduce system complexity, enabling easier maintenance and optimizing performance.5. Temperature and Pressure Resistance:Engineered with high temperature and pressure tolerance in mind, Teflon Lined Fittings offer exceptional operational versatility. These fittings can withstand elevated temperatures up to 220°C (428°F) and pressures up to 16 bar (232 psi), making them suitable for a broad spectrum of demanding applications. The ability to handle extreme conditions ensures the overall safety and reliability of the connected systems.6. Installation and Maintenance Convenience:The innovative design of Teflon Lined Fittings emphasizes easy installation, allowing for efficient integration into existing piping systems. With a variety of connection options, including flanged, threaded, and welded, these fittings provide flexibility, further simplifying installation procedures. Moreover, their low maintenance requirements contribute to cost savings and minimize downtime.7. Recognizing Industry Standards:[Company Name] manufactures its Teflon Lined Fittings in compliance with international standards and industry regulations. These fittings adhere to ASTM (American Society for Testing and Materials) standards, ensuring consistent and reliable performance across different industrial sectors. Customers can trust that these fittings meet the highest quality benchmarks and are backed by extensive research and development.Conclusion:[Company Name]'s Teflon Lined Fittings offer an innovative and highly reliable solution for industries in need of efficient and corrosion-resistant piping systems. With their superior chemical compatibility, exceptional temperature and pressure resistance, and ease of installation, these fittings are set to revolutionize the field. By introducing this cutting-edge technology, [Company Name] continues to demonstrate its commitment to delivering advanced industrial solutions that meet the evolving needs of various industries worldwide.

Discover the Advantages of Bonded PTFE Sheet for Various Applications

[Introduction]Innovations in the field of materials science are continuously shaping various industries, and the latest development in the realm of polytetrafluoroethylene (PTFE) technology is making waves. An emerging player in this space, {Company Name}, has recently introduced a groundbreaking product known as the Bonded PTFE Sheet, revolutionizing how industries utilize this versatile material. With its unique properties and diverse range of applications, this innovative sheet is poised to transform multiple sectors, from medical and automotive to aerospace and engineering.[Overview of PTFE and its significance]PTFE is a synthetic fluoropolymer of tetrafluoroethylene that possesses exceptional chemical resistance, low coefficient of friction, as well as excellent electrical insulation properties. These qualities have made PTFE a highly sought-after material across various industries. However, traditional PTFE sheets are known to have limitations due to their relatively weak bond strength when it comes to bonding with other substrates such as metals or plastics.[Bonded PTFE Sheet: A game-changer]Recognizing the need for a more reliable and versatile solution, {Company Name} developed the Bonded PTFE Sheet, engineered to address the bonding challenges associated with traditional PTFE sheets. By employing advanced adhesive technology, this innovative sheet combines the remarkable properties of PTFE with enhanced bond strength, offering unprecedented possibilities and applications.The Bonded PTFE Sheet features an enhanced surface treatment, allowing it to form strong bonds with various materials, including metals, plastics, rubbers, and composites. This breakthrough innovation expands the scope of applications for PTFE sheets, enabling engineers and designers to explore new avenues in their projects.[Applications in the medical industry]The medical industry is one such sector that stands to benefit significantly from the introduction of the Bonded PTFE Sheet. Its exceptional chemical resistance, biocompatibility, and low friction properties make it an ideal choice for medical devices, implants, and pharmaceutical applications. The enhanced bond strength further ensures the longevity and reliability of medical instruments while providing an additional layer of safety to patients.[Revolutionizing the automotive and aerospace sectors]In the automotive industry, the Bonded PTFE Sheet offers a multitude of advantages. Its low coefficient of friction aids in reducing wear and tear between moving components, thereby enhancing the overall efficiency and lifespan of the vehicles. Furthermore, its chemical resistance makes it an excellent choice for gaskets, seals, and electrical insulation, ensuring optimal performance in various automotive applications.Likewise, in the aerospace sector, the Bonded PTFE Sheet provides an innovative solution for critical applications. Its ability to withstand extreme temperatures, resist corrosion, and maintain mechanical integrity even in harsh environments is paramount in aerospace engineering. The increased bond strength ensures that vital components can withstand the rigors of space travel, making this sheet an invaluable addition to the industry.[Diversity in engineering applications]The engineering industry, encompassing a wide range of disciplines, can also harness the potential offered by the Bonded PTFE Sheet. Its unique combination of properties makes it an exceptional material choice for applications such as electrical insulation, sealing, and anti-corrosion protection. The enhanced bond strength expands the possibilities for engineers, allowing them to use PTFE in conjunction with other materials, thereby unlocking new realms of innovation.[Conclusion]With the introduction of the Bonded PTFE Sheet, {Company Name} has undoubtedly taken a significant step forward in improving the functionality and versatility of PTFE. This innovative product opens up a myriad of possibilities in various industries, enabling engineers and designers to push boundaries and explore new frontiers. As technology continues to advance, the importance of materials like the Bonded PTFE Sheet cannot be overstated, making it a game-changer that will undoubtedly shape the future of multiple sectors.

A Guide to Amber Glass Reagent Bottles - Why They're Essential for Laboratory Use

Title: Ambershield Introduces Revolutionary Reagent Bottle for Enhanced Chemical Storage SafetyIntroduction:Ambershield, a global leader in laboratory equipment manufacturing, is excited to announce the launch of their innovative Reagent Bottle Amber Glass. Designed with utmost precision and incorporating the latest technological advancements, this groundbreaking product ensures improved chemical storage safety in laboratories, pharmaceutical research facilities, and industrial settings. Ambershield's focus on quality and customer satisfaction remains at the forefront, offering highly reliable and durable laboratory solutions that surpass industry standards.Enhancing Safety in Chemical Storage:When working with hazardous chemicals, proper handling and storage are of paramount importance to safeguard the well-being of scientists and minimize the risk of accidents. Traditional reagent bottles made from clear glass or plastic often fail to provide adequate protection against exposure to harmful UV light and harsh chemicals. Recognizing this crucial need, Ambershield has developed its Reagent Bottle Amber Glass, carefully engineered to safeguard the integrity of sensitive reagents and optimize safety precautions.Unparalleled Protection:The key feature of the Reagent Bottle Amber Glass is its superior light-filtering properties. The amber-colored glass effectively blocks harmful UV radiation, preventing degradation of light-sensitive substances stored within. This breakthrough technology ensures that delicate reagents and solutions remain stable and their integrity is preserved, reducing the risk of contamination and potential compromise in experimental outcomes.Furthermore, the high-quality borosilicate glass used in the manufacture of these bottles provides exceptional resistance to corrosion from a wide range of chemicals. The robust construction, coupled with Ambershield's stringent quality control processes, guarantees long-term durability, limiting the possibility of leaks or breakages that could jeopardize the safety of both personnel and the laboratory environment.Improved User Experience:Ambershield gives utmost priority to user convenience and ergonomics. The Reagent Bottle Amber Glass is intelligently designed with a wide mouth, facilitating effortless pouring and ensuring precise measurement of reagents. The bottle's airtight screw cap prevents accidental leaks and evaporation, maintaining the integrity of the stored chemicals, even in demanding laboratory environments.Easy Identification and Compliance:Ambershield understands the importance of efficient lab management and keeping in line with regulatory guidelines. The brand ensures all their Reagent Bottle Amber Glass products are clearly marked with calibrated volume indicators, facilitating accurate measurement and dosage. Additionally, each bottle is imprinted with chemical-resistant labels, ensuring proper identification, traceability, and compliance with safety regulations.Sustainable and Environmentally-Friendly Solutions:Ambershield is committed to environmental sustainability, and the Reagent Bottle Amber Glass is no exception. Made from high-quality recyclable borosilicate glass, these bottles can be reused numerous times without compromising their structural integrity. By investing in these eco-friendly reagent bottles, laboratories and pharmaceutical research facilities contribute to minimizing single-use plastic waste and promote a greener, more sustainable future.Availability and Future Prospects:Ambershield's Reagent Bottle Amber Glass is now available for purchase through their trusted global network of distributors. With a comprehensive range of sizes and capacities, Ambershield caters to the diverse storage needs of laboratories worldwide. Furthermore, Ambershield's commitment to continuous improvement ensures constant research and development, guaranteeing the introduction of advanced lab equipment solutions that meet the evolving requirements of scientific advancements.Conclusion:Ambershield's Reagent Bottle Amber Glass represents a significant breakthrough in enhancing chemical storage safety. By combining cutting-edge technology, rigorous quality standards, and a commitment to customer satisfaction, Ambershield once again reaffirms its position as a global leader in laboratory equipment manufacturing. The advanced protective properties, user-friendly design, and eco-friendly nature make the Reagent Bottle Amber Glass the ultimate choice for laboratories seeking enhanced safety and optimal preservation of sensitive reagents.

Discover the Benefits of High-Quality PTFE Thread Seal Tape for Effective Sealing

Title: Innovations in Thread Seal Tapes: Revolutionizing Plumbing and Industrial ApplicationsIntroduction:In today's rapidly evolving world of industrial advancements, companies are continually pushing the boundaries of technology to bring innovation and improved efficiency to various industries. One such company leading the charge is Harvey Inc., a renowned manufacturer in the plumbing and industrial sector. With its recent breakthrough, Harvey has unveiled a game-changing product: a highly effective thread seal tape that is set to revolutionize plumbing and industrial applications.Harvey's Ptfe Thread Seal Tape:Harvey's Ptfe Thread Seal Tape is a cutting-edge product designed to provide impeccable sealing performance, versatility, and ease of use. Made from high-quality PTFE (Polytetrafluoroethylene), this specialized tape goes beyond conventional sealing methods, ensuring secure joints and preventing leakage in plumbing and industrial systems. Furthermore, its unique characteristics enable it to withstand extreme temperatures, chemical exposure, and high-pressure environments, making it an invaluable asset across multiple sectors.Superior Features and Benefits:1. Extended Lifespan: Harvey's Ptfe Thread Seal Tape offers exceptional longevity due to its top-grade materials and impeccable manufacturing processes. Its superior durability ensures long-lasting, reliable performance, reducing maintenance costs and downtime significantly.2. Enhanced Efficiency: With a strong focus on user convenience, Harvey's thread seal tape features a self-lubricating nature that reduces friction during installation. This not only streamlines the process but also reduces the chance of misalignments and accidental damage, leading to improved efficiency and increased productivity.3. Uncompromised Sealing: The Ptfe thread seal tape ensures airtight and waterproof seals. Its unique composition allows it to conform to irregular surfaces, thereby eliminating gaps that might otherwise lead to leakage. Its high-tensile strength provides a secure and long-lasting seal that endures even in the most demanding applications.4. Versatile Applications: Offering exceptional compatibility with different materials such as metals, plastics, and rubber, Harvey's Ptfe Thread Seal Tape caters to a wide range of industries. From plumbing and HVAC systems to chemical plants and industrial pipelines, this versatile sealing solution caters to diverse applications, bringing heightened reliability to various sectors.Company Commitments and Further Developments:Harvey Inc. has always prioritized customer satisfaction and continually strives to provide groundbreaking solutions. By leveraging their expertise and industry-leading research and development capabilities, the company firmly believes in continuously improving their products. Feedback from customers and industry experts plays a vital role in further refining their offerings, ensuring they remain at the forefront of technological advancements.Additionally, Harvey's commitment to sustainability is evident in its manufacturing practices. The Ptfe thread seal tape is developed with environmentally friendly processes and materials, reducing waste and minimizing its carbon footprint. This dedication to sustainability aligns with the increasing global focus on eco-friendly solutions.Conclusion:In an ever-evolving industrial landscape, Harvey Inc.'s Ptfe Thread Seal Tape represents a significant step forward in sealing technology. With its superior features, durability, and versatility, this innovative product is set to revolutionize plumbing and industrial applications. Harvey's commitment to customer satisfaction, sustainability, and continuous improvement positions them as a leader in the field, ensuring a brighter future for the industries they serve.

The Importance of Hose Thread Tape for Leak-Proof Connections

[Title]: Innovative Hose Thread Tape Sets New Standards in Plumbing Industry[Subtitle]: Company X Revolutionizes Plumbing Solutions with Cutting-Edge Hose Thread Tape[Date]: [Enter Current Date][City, State]: [Enter City Name], [Enter State Name] - Renowned for their dedication to delivering pioneering solutions in the plumbing industry, Company X has unveiled their latest innovation - a groundbreaking hose thread tape that is set to redefine the way plumbers and homeowners approach plumbing installations and repairs. With its unrivaled durability, ease of use, and performance, this new product is poised to become an indispensable tool in every plumber's toolkit.Company X has been an industry leader for over a decade, consistently pushing the boundaries to develop innovative plumbing solutions that streamline processes and improve efficiency. Their commitment to quality and customer satisfaction has earned them an exceptional reputation within the industry. This new hose thread tape is yet another testament to their unwavering pursuit of excellence.The design team at Company X invested countless hours of research and development into perfecting this game-changing hose thread tape. The result is a tape that offers an unparalleled level of performance and reliability. Crafted using advanced materials and production techniques, this tape is built to withstand the most demanding plumbing applications.One of the standout features of this hose thread tape is its exceptional strength and durability. Unlike traditional tapes that can easily tear or degrade over time, this tape is specifically engineered to resist wear and tear, ensuring a long-lasting and leak-free seal. Plumbers and homeowners no longer have to worry about frequent reapplications or pesky leaks.Furthermore, the tape's user-friendly design makes it incredibly easy to work with. Its unique composition allows for smooth handling and hassle-free application. Plumbers will no longer have to struggle with unraveling or tearing tape, providing significant time savings during installations and repairs. This user-centric approach is a hallmark of Company X's commitment to customer satisfaction.Additionally, the hose thread tape's enhanced performance extends beyond its durability and ease of use. It is specially formulated to offer an exceptional level of sealing performance, ensuring leaks are effectively prevented. This feature makes it an essential tool for both simple plumbing repairs and complex installations, addressing the needs of professionals and DIY enthusiasts alike.Company X's new hose thread tape is also environmentally friendly. Manufactured using sustainable materials and processes, it aligns with the company's commitment to reducing its environmental impact. Plumbers and homeowners can now make conscientious choices without compromising on quality or performance.To ensure maximum accessibility, Company X will be making this innovative hose thread tape available for purchase through their extensive network of distributors and retailers. With their widespread presence, customers can easily procure this groundbreaking product without any hassle.In conclusion, Company X's revolutionary hose thread tape is poised to shape the future of the plumbing industry. With its exceptional durability, ease of use, and sealing performance, it sets a new standard for plumbing solutions. By merging cutting-edge technology with environmental consciousness, Company X continues to demonstrate their leadership and commitment to providing innovative products that exceed customer expectations.

Valuable Insights on Elastomeric Neoprene Bearing Pads Revealed in Recent News

Title: Innovative Bearing Solution Revolutionizes Structural Stability in Construction IndustryIntroduction:In the ever-evolving construction industry, ensuring structural stability and durability is of paramount importance. Addressing this need, a leading company specializing in engineering solutions has developed an innovative product that sets new standards in structural support systems. The Elastomeric Neoprene Bearing Pad combines superior functionality, durability, and versatility, making it an indispensable component in modern construction projects.I. The Evolving Needs of the Construction IndustryThe construction industry is witnessing progress at an unprecedented pace, with the demand for large-scale infrastructure projects on the rise. As buildings become taller, bridges span greater distances, and roads support heavier vehicles, engineers are confronted with the challenge of maintaining safety and stability. The need for reliable bearing pads that can absorb shocks, accommodate movements, and enhance structural resilience has become more essential than ever before.II. Introducing the Elastomeric Neoprene Bearing Pad (remove brand name)Recognizing the industry's demands, {Company Name}, a leader in engineering solutions, has introduced the Elastomeric Neoprene Bearing Pad. This cutting-edge product combines the mechanical properties of high-quality elastomers with the versatility and durability of neoprene. Designed to withstand heavy loads, seismic activities, temperature fluctuations, and structural movements, the Elastomeric Neoprene Bearing Pad offers unmatched support to various construction projects across different sectors.III. Superior Functionality and PerformanceThe Elastomeric Neoprene Bearing Pad is engineered to perform reliably under extreme conditions, providing crucial support to bridges, highways, buildings, and other infrastructure projects. Its unique composition enables multidirectional movements, allowing the structure to accommodate external forces like seismic activity and thermal expansion. Furthermore, its resilient properties provide excellent energy absorption, thus reducing vibrations and impacts on the structure. This innovative product significantly enhances safety and longevity while minimizing maintenance costs.IV. Key Advantages of Elastomeric Neoprene Bearing Pad1. Durability and Longevity: The Elastomeric Neoprene Bearing Pad's robust construction ensures its longevity and resistance to wear, tear, and degradation. It can withstand environmental factors such as UV radiation, temperature variations, and chemical exposure, thereby contributing to the overall durability of the structure.2. Versatility: The bearing pad's versatility allows it to be customized according to specific project requirements. It can be designed in various shapes, sizes, and load-bearing capacities, making it a suitable solution for projects ranging from simple structures to complex mega-infrastructure developments.3. Cost-Effective Solution: By minimizing the potential for structural damage caused by movements and vibrations, the Elastomeric Neoprene Bearing Pad reduces the need for frequent repairs, maintenance, and replacements. This leads to cost savings for project owners and contractors.V. Applications in the Construction IndustryThe applications of the Elastomeric Neoprene Bearing Pad are vast and diverse. Its usage extends to the construction and renovation of bridges, highways, railways, buildings, sports facilities, and seismic isolation systems. With its ability to withstand heavy loads, movements, and vibrations, this innovative bearing pad provides enhanced safety for both domestic and international construction projects.VI. ConclusionThe introduction of the Elastomeric Neoprene Bearing Pad by {Company Name} signifies a revolutionary breakthrough in the construction industry. Its unmatched functionality, durability, and versatility make it an indispensable component for engineers and architects seeking reliable structural support systems. As large-scale projects continue to shape the future of the construction industry, this innovative product paves the way for safer and more resilient structures, further emphasizing the commitment to progress and excellence in modern construction practices.

Sustainable and Eco-Friendly Agent Bottle: The Newest Solution for All Your Needs

Title: Innovative Reusable Bottle Revolutionizes How We HydrateIntroduction:In recent years, concerns regarding plastic waste and its impact on the environment have intensified. As a result, companies worldwide have begun to seek alternatives to single-use plastic products. One such innovative solution is the Re Agent Bottle, an eco-friendly and durable reusable bottle that is set to revolutionize the way we hydrate. Designed and produced by a leading company dedicated to sustainability, the Re Agent Bottle is making waves as it aims to tackle diverse environmental challenges associated with disposable bottles.1. Environmental Benefits:The Re Agent Bottle addresses the glaring issue of plastic waste by offering a sustainable alternative to disposable bottles. Manufactured using premium-quality materials, the bottle is designed to be both reusable and long-lasting. By promoting repeated use, it significantly reduces the amount of single-use plastic waste generated. This eco-conscious approach aligns perfectly with the company's commitment to creating a greener future.2. Innovative Design and Features:The Re Agent Bottle incorporates innovative design elements that prioritize functionality, convenience, and user experience. Its leak-proof cap ensures mess-free portability, making it ideal for travel, outdoor adventures, or day-to-day use. The bottle's ergonomic shape and lightweight construction make it easy to hold and carry, while the wide mouth allows for hassle-free filling, cleaning, and adding ice cubes. Available in a range of sizes and vibrant colors, the Re Agent Bottle caters to diverse customer preferences.3. Durability:Distinguishing itself from many other reusable bottles on the market, the Re Agent Bottle is built to withstand the rigors of daily use. Its robust construction ensures long-lasting durability, reducing the need for frequent replacements and further minimizing plastic waste. Whether it's for hot or cold beverages, the bottle's premium insulation properties keep liquids at the desired temperature for extended periods.4. BPA-Free Material:The Re Agent Bottle is manufactured using high-quality, BPA-free materials, ensuring it is safe for everyday use. By implementing rigorous quality control measures, the company guarantees that each bottle adheres to the highest industry standards. This commitment to safety makes the Re Agent Bottle a reliable choice for health-conscious individuals seeking eco-friendly hydration solutions.5. Corporate Social Responsibility:The company behind the Re Agent Bottle is dedicated to corporate social responsibility and sustainable business practices. In addition to producing environmentally friendly products, they actively engage in initiatives aimed at reducing plastic pollution and promoting recycling. Furthermore, a percentage of profits from each Re Agent Bottle sold is donated to organizations focused on environmental conservation, reinforcing the company's commitment to making a positive impact.Conclusion:In a time where the environmental consequences of plastic waste have become impossible to ignore, the Re Agent Bottle serves as a practical, eco-friendly solution. Combining innovative design, durability, and sustainability, it embodies the future of reusable bottles. With its positive impact on the environment, user-centric features, and commitment to corporate social responsibility, the Re Agent Bottle has positioned itself as a leading contender in the endeavor to reduce single-use plastic waste and create a greener planet for generations to come.

Boost Your Projects with Heat-Resistant PTFE Thread Seal Tape

Title: PTFE Thread Seal Tape: A Superior Heat-Resistant Solution for Enhanced SealingIntroduction:In today's dynamic market, industries are constantly on the lookout for innovative ways to improve their product quality and efficiency. Recognizing this need, (Company Name) has developed a breakthrough solution in the form of PTFE (polytetrafluoroethylene) Thread Seal Tape - a product that offers superior heat resistance and sealing capabilities. With this novel development, (Company Name) aims to revolutionize the industry and serve as a key source of reliable and efficient sealing solutions.Expanding on the Company's Background:Founded in (Year of Establishment), (Company Name) holds a prominent position in the industry, boasting a rich legacy of excellence in developing cutting-edge solutions. With a team of passionate and experienced professionals, the company has maintained a strong focus on research and development, enabling them to consistently introduce innovative products that cater to the ever-evolving needs of their customers.PTFE Thread Seal Tape - Unparalleled Heat Resistance:In industries where high temperatures and demanding conditions are prevalent, the quality and reliability of seals are of utmost importance. (Company Name)'s PTFE Thread Seal Tape serves as an ideal solution, offering exceptional heat resistance and durability. This tape is manufactured using high-quality PTFE material, recognized for its outstanding resistance to heat, chemicals, and aging.Key Features and Benefits:1. Extreme Heat Resistance: Withstanding temperatures up to (insert temperature range), the PTFE Thread Seal Tape remains robust and maintains its sealing capabilities even in extremely demanding environments. This offers significant advantages, particularly in applications involving steam systems, boilers, and high-temperature hydraulic systems.2. Superior Chemical Resistance: In addition to heat resistance, this innovative tape exhibits excellent chemical resistance, making it ideal for use in a wide range of industries, such as chemical processing, petrochemicals, and oil and gas. The PTFE material restricts the tape from reacting with various chemicals, ensuring enhanced safety and longevity of the seals.3. Versatility and Compatibility: The PTFE Thread Seal Tape is extremely versatile, compatible with a wide range of pipe materials, including metal, plastic, and composite pipes. This flexibility enables businesses to streamline their operations, cut costs, and simplify inventory management by utilizing a single sealant for various applications.4. Enhanced Sealing Performance: The unique properties of PTFE Thread Seal Tape allow it to provide an effective sealing solution, preventing leaks even under high pressure conditions. This feature makes it highly desirable for industries such as plumbing, HVAC, and manufacturing, where tight sealing is crucial for system efficiency and performance.5. Easy Application: (Company Name)'s PTFE Thread Seal Tape has been designed for easy application and hassle-free installation. The tape is conveniently packaged in rolls, enabling users to effortlessly measure and cut the desired length, ensuring consistent and accurate sealing.Conclusion:The introduction of (Company Name)'s PTFE Thread Seal Tape represents a significant advancement in the sealing industry, providing businesses with a reliable, heat-resistant, and versatile solution. With its exceptional heat resistance, chemical compatibility, and enhanced sealing performance, this innovative tape offers a multitude of advantages across various industries. As (Company Name) continues to lead the way in developing ingenious sealing solutions, this revolutionary product stands poised to transform and elevate industrial operations, maximizing efficiency and ensuring superior performance.