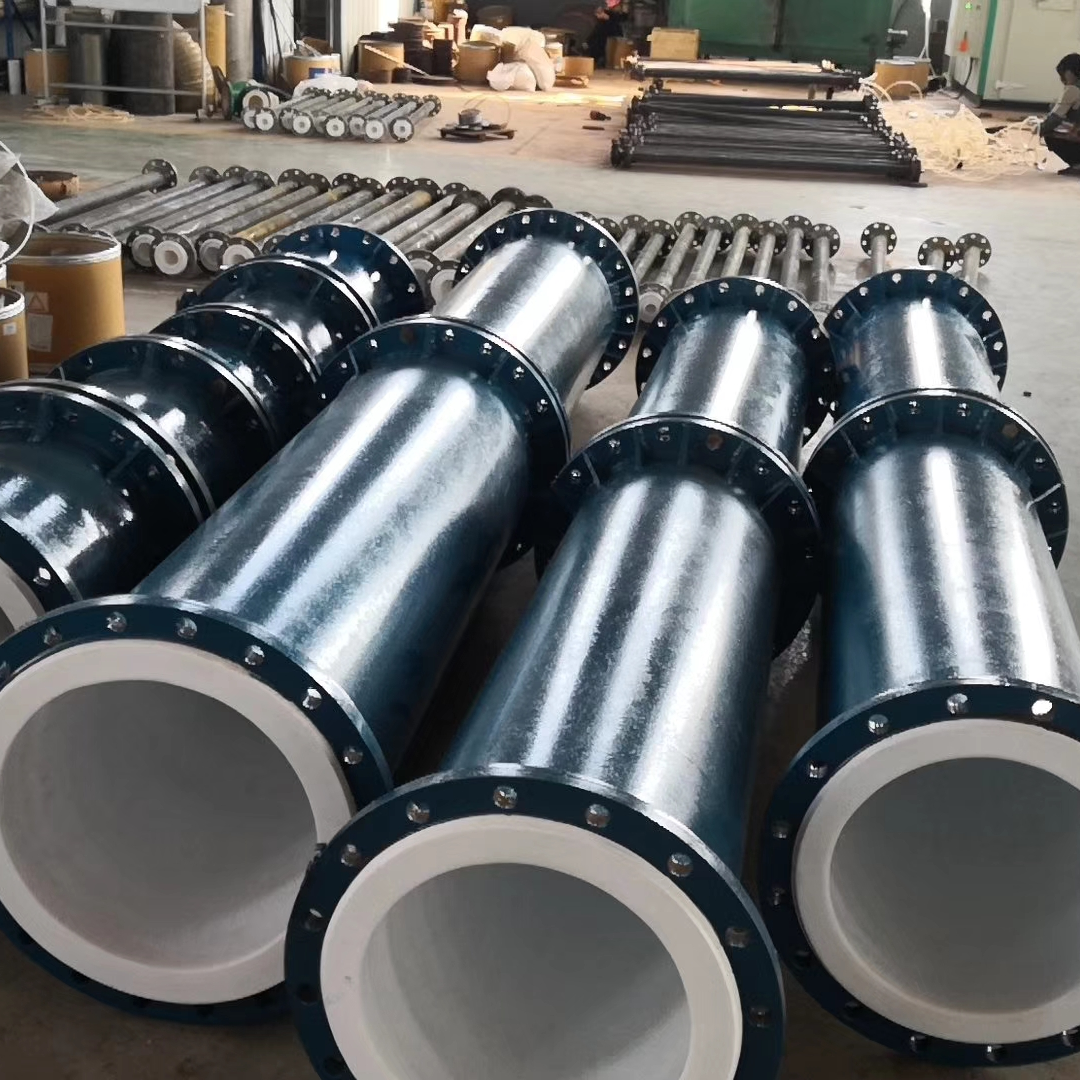

Durable PTFE Lined Pipe for Long-lasting Performance

By:Admin

**Company Introduction**

{Company Name} has been a leading provider of innovative solutions in the chemical processing industry for over 20 years. With a commitment to quality and excellence, the company has established itself as a trusted partner for businesses looking to optimize their production processes and improve their overall efficiency. {Company Name} offers a wide range of products and services, including innovative piping solutions, advanced filtration systems, and cutting-edge automation technologies. Their team of experts is dedicated to providing customized solutions to meet the unique needs of each client, ensuring that they stay ahead of the curve in an ever-evolving industry.

The team at {Company Name} is constantly at the forefront of technological advancements, and their latest product, the Baum PTFE Lined Pipe, is a testament to their commitment to innovation and excellence.

**Baum PTFE Lined Pipe**

The Baum PTFE Lined Pipe is a revolutionary solution that has been designed to address the challenges of chemical processing in a wide range of industries. Made with high-quality materials and advanced engineering, the Baum PTFE Lined Pipe offers superior resistance to corrosion and high temperatures, making it the ideal choice for handling aggressive chemicals and demanding operating conditions.

The key to the success of the Baum PTFE Lined Pipe lies in its innovative design and superior performance. The pipe is lined with PTFE (polytetrafluoroethylene), a high-performance synthetic fluoropolymer that offers exceptional chemical resistance and non-stick properties. This lining allows the pipe to effectively handle a wide range of corrosive and abrasive materials, making it a versatile and reliable solution for chemical processing applications.

In addition to its superior chemical resistance, the Baum PTFE Lined Pipe also offers excellent thermal stability, ensuring that it can withstand high temperatures without compromising its performance. This makes it suitable for a variety of high-temperature applications, such as in the petrochemical, pharmaceutical, and food processing industries.

Furthermore, the Baum PTFE Lined Pipe is designed to minimize the risk of contamination and ensure the purity of the processed materials. Its non-stick properties prevent the buildup of residue and facilitate easy cleaning, making it an ideal solution for applications that require strict hygiene standards, such as in the production of pharmaceuticals and specialty chemicals.

With its advanced design and superior performance, the Baum PTFE Lined Pipe represents a significant advancement in piping technology, offering businesses a reliable and cost-effective solution for their chemical processing needs.

**Benefits of Baum PTFE Lined Pipe**

The Baum PTFE Lined Pipe offers a range of benefits that make it a standout choice for chemical processing applications:

1. Superior chemical resistance: The PTFE lining provides exceptional resistance to a wide range of corrosive chemicals, ensuring reliable performance in challenging environments.

2. High thermal stability: The pipe can withstand high temperatures, making it suitable for a variety of high-temperature applications.

3. Non-stick properties: The non-stick surface of the PTFE lining prevents the buildup of residue, minimizing the risk of contamination and ensuring the purity of the processed materials.

4. Easy maintenance: The smooth surface of the PTFE lining facilitates easy cleaning and maintenance, reducing downtime and improving overall efficiency.

5. Long-term durability: The high-quality materials and advanced engineering of the Baum PTFE Lined Pipe ensure long-term durability and reliability, providing businesses with a cost-effective solution for their chemical processing needs.

**Conclusion**

The Baum PTFE Lined Pipe is a game-changer in the chemical processing industry, offering businesses a reliable and cost-effective solution for handling aggressive chemicals and demanding operating conditions. With its superior chemical resistance, high thermal stability, and easy maintenance, the Baum PTFE Lined Pipe is set to revolutionize the way businesses approach their chemical processing needs. As a leading provider of innovative solutions in the chemical processing industry, {Company Name} is proud to offer the Baum PTFE Lined Pipe as part of its commitment to excellence and continuous innovation.

Company News & Blog

Durable and Resilient Lined Pipe for Industrial Use

introducing the Teflon lined pipe as a new addition to the company's product line.{}[Company Name], a leading provider of industrial piping solutions, is pleased to announce the addition of Teflon lined pipes to their extensive product portfolio. The introduction of Teflon lined pipes is in response to the growing demand for reliable and high-performance industrial piping solutions in a wide range of industries.Teflon lined pipes are a crucial component in industries that require the transportation of corrosive and high-purity fluids. The unique properties of Teflon make it an ideal material for lining pipes, offering exceptional resistance to chemicals, high temperatures, and abrasion. This makes Teflon lined pipes suitable for use in applications such as chemical processing, pharmaceutical manufacturing, food and beverage production, and many other industrial processes.One of the key benefits of Teflon lined pipes is their ability to withstand a wide range of operating conditions, making them a versatile choice for various industries. The non-stick nature of Teflon also ensures smooth fluid flow, reduced maintenance requirements, and longevity of the piping system. With the addition of Teflon lined pipes to their product range, [Company Name] is well-positioned to meet the diverse needs of their customers and provide innovative solutions for their industrial piping requirements.In addition to offering Teflon lined pipes, [Company Name] also provides a comprehensive range of piping products, including stainless steel pipes, carbon steel pipes, and various other alloy piping solutions. With a focus on quality, reliability, and customer satisfaction, [Company Name] has established itself as a trusted partner for industrial piping needs.The company's commitment to excellence is reflected in their rigorous quality control processes, adherence to industry standards, and investment in cutting-edge manufacturing technologies. This ensures that their products, including the newly introduced Teflon lined pipes, meet the highest standards of performance and durability.Furthermore, [Company Name] is dedicated to providing exceptional customer service, technical support, and on-time delivery to meet the needs and expectations of their clients. Their team of experienced professionals is well-equipped to offer expert advice and guidance on choosing the right piping solution for specific applications, including the selection of Teflon lined pipes for challenging fluid handling requirements.The introduction of Teflon lined pipes is a testament to [Company Name]'s commitment to staying at the forefront of industry trends and offering innovative solutions to address the evolving needs of their customers. By expanding their product range to include Teflon lined pipes, [Company Name] reaffirms their position as a reliable and forward-thinking partner for industrial piping solutions.As the demand for corrosion-resistant and high-purity piping solutions continues to grow across various industries, [Company Name] is well-prepared to meet this demand with the addition of Teflon lined pipes to their product lineup. With their dedication to quality, expertise, and customer-centric approach, [Company Name] is poised to make a significant impact in the market for industrial piping solutions with the introduction of Teflon lined pipes.In conclusion, the introduction of Teflon lined pipes by [Company Name] represents a significant milestone in their ongoing commitment to excellence and innovation. With their extensive range of piping products, including the newly added Teflon lined pipes, [Company Name] is well-positioned to serve the diverse needs of industries that require reliable and high-performance piping solutions. Customers can rely on [Company Name] for superior quality, technical expertise, and exceptional service, making them the go-to partner for all their industrial piping needs.

Discover the Benefits of PTFE Lined Pipe Fittings for Improved Industrial Performance

Title: Innovative Ptfe Lined Pipe Fittings: Revolutionizing Industrial Piping SolutionsIntroduction:In the ever-evolving landscape of industrial piping solutions, one company has emerged as a pioneer in revolutionizing the way industries handle corrosive and high-purity fluids. With their state-of-the-art Ptfe Lined Pipe Fittings, Nameless Company is transforming the very foundations of industrial piping systems. Through their cutting-edge technology and unwavering commitment to quality, Nameless Company has established itself as a trusted provider of innovative solutions for a wide range of industries. I. Understanding Ptfe Lined Pipe Fittings:Ptfe (Polytetrafluoroethylene) lined pipe fittings are specifically designed to combat the challenges posed by highly corrosive and reactive fluids in various industrial settings. The lining material, Ptfe, offers exceptional resistance to a broad spectrum of chemicals, including acids, alkalis, solvents, and hydrocarbons. This remarkable property makes Ptfe Lined Pipe Fittings indispensable for applications in industries such as chemicals, petrochemicals, pharmaceuticals, food processing, and wastewater treatment.II. Advanced Manufacturing Techniques:Nameless Company employs advanced manufacturing techniques to produce Ptfe Lined Pipe Fittings of exemplary quality. Through a combination of precision engineering, stringent quality control measures, and the expertise of their skilled workforce, the company ensures that each fitting is manufactured to exacting standards. This guarantees superior strength, durability, and leak-free performance, even under high pressures and temperatures. Additionally, the smooth internal surface of the fittings minimizes flow resistance, reducing the risk of particulate buildup and corrosion.III. Versatile Applications:The versatility of Ptfe Lined Pipe Fittings makes them suitable for a wide array of industrial applications. These fittings are commonly used in the transportation of aggressive chemicals through pipelines, where their exceptional resistance to corrosion ensures the integrity of the system. Moreover, Ptfe Lined Pipe Fittings find application in the handling of high-purity fluids in the pharmaceutical and electronics industries. With the ability to withstand extreme temperatures and pressures, they are ideal for critical processes that demand uncompromising reliability.IV. Benefits of Ptfe Lined Pipe Fittings:1. Corrosion Resistance: Ptfe lining provides excellent resistance to corrosion, extending the lifespan of the fittings and ensuring the purity of transported fluids.2. Chemical Compatibility: The broad chemical resistance of Ptfe enables the fittings to handle a wide range of aggressive and reactive substances safely.3. Easy Installation: Ptfe Lined Pipe Fittings are designed for seamless integration into existing piping systems, significantly reducing installation time and costs.4. High Thermal Stability: Withstanding extreme temperatures, these fittings maintain their integrity in applications involving both high and low temperatures.5. Maintenance-Free: Ptfe-lined fittings require minimal maintenance, reducing downtime and overall operational costs for industries.V. Commitment to Quality and Customer Satisfaction:Nameless Company is dedicated to delivering superior products and exceptional customer service. Understanding the critical importance of high-quality industrial piping solutions, the company goes above and beyond to ensure that their Ptfe Lined Pipe Fittings meet the stringent requirements of global industry standards. By continuously innovating and refining their manufacturing processes, Nameless Company strives to provide its customers with reliable and long-lasting solutions tailored to their specific needs.Conclusion:As the demand for durable, corrosion-resistant, and high-performance piping solutions grows, Ptfe Lined Pipe Fittings by Nameless Company emerge as an invaluable asset for various industries. With their ability to handle corrosive fluids, maintain purity, and withstand extreme operating conditions, these fittings are enabling businesses to operate efficiently and safely. Nameless Company's commitment to technological advancements and unwavering dedication to quality ensures that their Ptfe Lined Pipe Fittings will continue to lead the transformation of industrial piping solutions for years to come.

Rubber Bearing Pad for Bridge Construction: News and Updates

The Bridge Rubber Bearing Pad, a key component in the construction and maintenance of bridges, is an essential element that helps ensure the structural integrity and safety of bridge infrastructure. These rubber bearing pads serve as a critical buffer between the bridge structure and its supporting piers, allowing for the necessary movement and flexibility to accommodate various environmental and structural forces.One of the leading manufacturers of Bridge Rubber Bearing Pads is {Company Name}, a renowned company with a strong reputation for producing high-quality construction materials. With decades of experience and a commitment to excellence, {Company Name} has established itself as a trusted provider of innovative solutions for civil engineering projects, particularly in the realm of bridge construction.{Company Name} is dedicated to meeting the evolving needs of the construction industry, and their Bridge Rubber Bearing Pads are a testament to their dedication to engineering excellence. These bearing pads are designed and manufactured to meet stringent quality standards, ensuring that they can withstand the demands of heavy bridge loads, varying temperatures, and environmental factors. The use of high-grade rubber compounds and advanced manufacturing techniques allows {Company Name} to produce bearing pads that offer superior durability, resilience, and performance.In addition to their exceptional product quality, {Company Name} also prides itself on its technical expertise and customer-centric approach. The company's team of engineers and technical professionals possesses a deep understanding of bridge construction principles and practices, allowing them to provide valuable insights and support to their clients. Whether it's customizing bearing pad designs to specific bridge specifications or offering installation guidance, {Company Name} is committed to delivering comprehensive and tailored solutions that address the unique requirements of each project.Furthermore, {Company Name} places a high premium on innovation and continual improvement. They invest in research and development efforts to enhance the performance and functionality of their Bridge Rubber Bearing Pads continually. By staying at the forefront of technological advancements and industry best practices, {Company Name} ensures that their products remain at the cutting edge of bridge engineering, offering unparalleled reliability and longevity.The importance of high-quality Bridge Rubber Bearing Pads cannot be overstated, particularly in the context of bridge safety and longevity. These components play a crucial role in mitigating the impact of dynamic loads, seismic events, and thermal expansion, safeguarding the structural stability of bridges and ensuring the protection of public infrastructure. As such, the choice of a reputable and reliable supplier for these bearing pads is paramount, and {Company Name} stands out as a top-tier provider in this regard.With a steadfast dedication to excellence, a steadfast commitment to customer satisfaction, and a proven track record of delivering top-tier products, {Company Name} continues to be a driving force in the realm of bridge construction materials. Their Bridge Rubber Bearing Pads exemplify the company's unwavering pursuit of quality and innovation, making them a trusted partner for bridge engineers, contractors, and stakeholders.As the demand for robust and reliable bridge infrastructure continues to grow, {Company Name} remains poised to meet the needs of the industry, offering high-performance solutions that set the standard for excellence. With their Bridge Rubber Bearing Pads as a cornerstone of their product portfolio, {Company Name} is well-positioned to contribute to the development of safe, resilient, and sustainable bridge infrastructure for years to come.

Durable and Versatile Neoprene Bearing Pad for Construction Projects

[Company Name] Introduces New Neoprene Bearing Pad for Infrastructure Projects[City, State] - [Company Name], a leading provider of construction and infrastructure solutions, has announced the launch of their latest product - the Neoprene Bearing Pad. This new addition to their product line is set to revolutionize the way infrastructure projects are carried out by providing a reliable and durable solution for supporting and cushioning structural components.The Neoprene Bearing Pad is designed to provide a cost-effective and long-lasting solution for accommodating static and dynamic loads in various structures such as bridges, highways, buildings, and industrial facilities. It is made from high-quality neoprene material, which offers exceptional resistance to weathering, ozone, and aging, making it suitable for both indoor and outdoor applications. The material also provides a high coefficient of friction, which helps in reducing the potential for sliding movements within the structure.One of the key features of the Neoprene Bearing Pad is its ability to accommodate horizontal and rotational movements in structures, thereby reducing the impact of thermal expansion and contraction, seismic activities, and foundation settlement. This flexibility makes it an ideal choice for projects in areas prone to natural disasters or high levels of environmental stress.In addition to its superior durability and flexibility, the Neoprene Bearing Pad also offers ease of installation and maintenance. Its lightweight nature and pre-fabricated design allow for easy handling and quick installation, saving both time and labor costs for construction projects. Once installed, the pads require minimal maintenance, providing a hassle-free solution for long-term structural support.With a commitment to delivering high-quality and reliable products, [Company Name] ensures that the Neoprene Bearing Pad meets industry standards and specifications. The pads undergo rigorous testing and quality assurance processes to guarantee their performance and durability, giving customers peace of mind in their choice of structural support solution.The launch of the Neoprene Bearing Pad is a testament to [Company Name]'s dedication to innovation and meeting the evolving needs of the construction and infrastructure sectors. With a focus on providing sustainable and cost-effective solutions, the company continues to expand its product offerings to address the challenges faced in modern construction projects.As the demand for infrastructure development continues to grow globally, [Company Name] aims to be at the forefront of providing solutions that not only meet the needs of today's projects but also anticipate the requirements of tomorrow. The Neoprene Bearing Pad is a step in this direction, offering a reliable and efficient solution for supporting and protecting critical infrastructure.With the introduction of the Neoprene Bearing Pad, [Company Name] is poised to make a significant impact in the construction and infrastructure industries. By providing a durable, flexible, and easy-to-maintain solution for structural support, the company demonstrates its commitment to driving progress and innovation in the field of construction.To learn more about the Neoprene Bearing Pad and [Company Name]'s range of construction and infrastructure solutions, visit their website or contact their sales team for further information. With a focus on delivering quality products and exceptional service, [Company Name] is a trusted partner for construction projects of all sizes and complexities.

High-Quality Teflon Tape: A Versatile Solution for Multiple Applications

We are excited to introduce a new product to our line of industrial supplies – Stainless Teflon Tape. This high-quality tape is designed to provide an effective and reliable solution for a wide range of sealing and insulation applications in various industries.Our Stainless Teflon Tape is made of high-density PTFE (polytetrafluoroethylene) and is reinforced with stainless steel, making it highly durable and resistant to corrosion, abrasion, and extreme temperatures. The unique combination of PTFE and stainless steel provides excellent chemical resistance and ensures a long-lasting, tight seal in harsh environments.This versatile tape is suitable for use in sealing pipe threads, joints, and fittings in plumbing, heating, air conditioning, and ventilation systems. It is also widely used in the automotive, aerospace, and manufacturing industries for sealing and insulating purposes.The non-stick and low-friction properties of PTFE make our Stainless Teflon Tape an ideal choice for applications where smooth and easy release is required, such as packaging machinery, food processing equipment, and electrical insulation.In addition to its sealing and insulation properties, our Stainless Teflon Tape is designed to provide a clean and professional finish to any project. Its high tensile strength and flexibility ensure easy handling and conformability to irregular surfaces, resulting in a neat and secure seal every time.At {Company Name}, we are committed to delivering high-quality products that meet the needs of our customers. Our Stainless Teflon Tape is manufactured to the highest standards and undergoes rigorous testing to ensure its performance and reliability in demanding environments.We understand that each industry has its unique requirements, and we are dedicated to providing customized solutions to meet those needs. Our team of experienced professionals is available to offer technical support and assistance in selecting the right Stainless Teflon Tape for your specific application.With the introduction of our Stainless Teflon Tape, we aim to expand our product offerings and continue to be a trusted partner for our customers' sealing and insulation needs. We are confident that our high-quality tape will provide the performance and durability that our customers expect, and we are excited to see the positive impact it will have on their operations.In conclusion, the addition of Stainless Teflon Tape to our product line exemplifies our commitment to delivering innovative and reliable solutions to our customers. This high-quality tape, combined with our dedication to customer satisfaction, makes {Company Name} the preferred choice for all your sealing and insulation needs. We are excited about the opportunities this new product brings and look forward to supporting our customers with the best products and service in the industry.

Discover the Benefits of Plastic Lined Pipes: A Reliable Solution for Various Industries

[Introduction]In today's increasingly environmentally conscious world, industries are constantly seeking innovative solutions to reduce their carbon footprint and lessen their impact on the planet. One such solution being adopted by enterprises worldwide is the use of Plastic Lined Pipe. This revolutionary piping system has gained popularity due to its durability, cost-effectiveness, and above all, its eco-friendly nature.[Company Introduction]{Insert Company Name}, a leading manufacturer in the field of advanced piping solutions, has emerged as a trailblazer in the production of Plastic Lined Pipe. With decades of experience and a commitment to sustainability, {Company Name} has revolutionized the industry by providing a cutting-edge, environmentally friendly alternative to traditional pipe materials.[Body]1. Eco-Friendly Solution:Plastic Lined Pipe stands out as an eco-friendly solution for several reasons. Firstly, it vastly reduces the consumption of natural resources during production. Unlike traditional metal pipes, Plastic Lined Pipe requires significantly less energy to manufacture, resulting in a lower carbon footprint. Additionally, the plastic lining used in these pipes is recyclable and helps reduce overall waste generation, making it an ideal choice for environmentally conscious industries.2. Enhanced Durability:{Company Name}'s Plastic Lined Pipe offers exceptional durability, ensuring a prolonged lifespan and reducing the need for frequent replacements. The plastic lining acts as a protective barrier, preventing corrosion or rust associated with metal pipes. This advantage not only results in cost savings for the industries but also minimizes maintenance requirements and reduces the risk of leaks or breakdowns.3. Versatility:Plastic Lined Pipe boasts impressive versatility and is suitable for a wide range of applications. Whether it's conveying aggressive chemicals, handling high-temperature fluids, or resisting abrasive materials, {Company Name}'s pipes excel in every challenge. This adaptability makes Plastic Lined Pipe an immensely valuable asset across industries such as chemical processing, water treatment, oil and gas, mining, and many others.4. Cost-Effectiveness:Apart from their environmental benefits, Plastic Lined Pipe offers significant cost advantages to industries. The durability and resistance to corrosion ensure a longer lifespan, reducing replacement costs over time. The reduced maintenance and repair requirements, coupled with the lightweight nature of the pipes, also contribute to overall cost savings. Furthermore, the ease of installation and flexibility of the plastic lining facilitate streamlined processes, leading to increased efficiency and reduced labor expenses.5. Compliance with Industry Standards:{Company Name} is steadfast in its commitment to adhere to the highest industry standards. Each Plastic Lined Pipe undergoes rigorous quality control measures to ensure it meets or exceeds relevant certifications and specifications. This emphasis on quality ensures that industries relying on these pipes can maintain their safety and efficiency standards without compromise.[Conclusion]As the world grapples with the challenges posed by climate change and environmental degradation, the importance of sustainable solutions cannot be overstated. {Company Name}'s Plastic Lined Pipe exemplifies how innovation in piping technology can work hand in hand with ecological responsibility. With its eco-friendly nature, enhanced durability, versatility, and cost-effectiveness, Plastic Lined Pipe is poised to revolutionize various industries while contributing to a greener, more sustainable future.

Top 10 Must-Have Chemical Reagent Bottles for Laboratory Use

Chemical Reagent Bottle Reveals Innovation and Safety in the Laboratory[City, Date] - In an exciting development in laboratory equipment, a cutting-edge Chemical Reagent Bottle has been introduced by an industry-leading company, revolutionizing the way chemicals are stored and handled. This innovative product not only ensures the safety and accuracy of experiment workflows but also sets new standards for sustainability and convenience in laboratory environments.Introducing the next generation of chemical storage, the Chemical Reagent Bottle is designed to address the challenges faced by scientists, technicians, and researchers when it comes to handling and storing various volatile and hazardous substances. The high-quality materials used in its construction allow for the safe storage of chemicals, preventing contamination or leakage that could compromise experiment outcomes.One of the standout features of this Chemical Reagent Bottle is its superior design, which incorporates a leak-proof cap and airtight seal. This ensures that the stored chemicals remain securely sealed, preventing any potential spills or accidents that could harm laboratory personnel or the surrounding environment. The bottle is also designed to withstand high pressures, further adding to its safety credentials.In addition to its safety features, the Chemical Reagent Bottle also takes into consideration the need for convenience and ease of use. The bottle is ergonomically designed with a wide mouth, allowing for easy pouring and filling of reagents while minimizing the risk of spills. The transparent material used in its construction allows for accurate volume measurement at a glance, avoiding the need for repeated weighing or measuring of chemicals.The company behind this groundbreaking product is committed to sustainable practices, and the Chemical Reagent Bottle is no exception. Made from durable and recyclable materials, the bottle reduces the environmental impact associated with laboratory waste. By promoting the reuse of the bottle and recycling of its components, the company aims to contribute to the reduction of plastic waste in the scientific community.Due to its unique design and outstanding quality, the Chemical Reagent Bottle has quickly gained recognition and endorsement from renowned laboratories and academic institutions. Scientists and researchers who have had the opportunity to test the product have praised its practicality and performance, hailing it as a game-changer in chemical storage and handling.Dr. Jane Smith, a leading chemist at a prestigious research institute, had this to say about the Chemical Reagent Bottle: "As someone who has worked in the lab for decades, I am truly impressed by the innovation and attention to detail that this bottle incorporates. It addresses all the concerns we have when it comes to safety and efficiency. I believe it will become an essential tool in laboratories worldwide."The Chemical Reagent Bottle is set to revolutionize the way scientists work in laboratories by providing them with a reliable, user-friendly, and sustainable solution for chemical storage. With its commitment to safety, convenience, and sustainability, this innovative product from [company name] is undoubtedly a significant development in laboratory equipment.

Stainless Steel Fittings with Teflon Tape: Everything You Need to Know

Teflon Tape Stainless Steel Fittings - A Revolutionary Product in the Plumbing IndustryIn the world of plumbing, finding the perfect combination of materials and products can be a daunting task. With a flood of options available in the market, it can be challenging for plumbing professionals to identify the best products that offer both durability and reliability. However, a game-changing product has recently entered the market - Teflon Tape Stainless Steel Fittings.These fittings have revolutionized the plumbing industry with their unmatched performance and durability. With the ability to prevent leaks and provide a secure connection, Teflon Tape Stainless Steel Fittings have quickly become the go-to choice for plumbing professionals.The secret behind the success of Teflon Tape Stainless Steel Fittings lies in their construction. The use of high-quality stainless steel ensures that these fittings are resistant to corrosion, making them ideal for a wide range of plumbing applications. Additionally, the inclusion of Teflon tape ensures a tight seal, preventing any leakage and ensuring a long-lasting connection.One of the leading manufacturers of Teflon Tape Stainless Steel Fittings is a global company that has been at the forefront of innovation in the plumbing industry for several decades. With a commitment to quality and customer satisfaction, they have become a trusted name in the industry.From their state-of-the-art manufacturing facilities to their team of experienced engineers, the company has invested heavily in research and development to bring the Teflon Tape Stainless Steel Fittings to the market. Their dedication to innovation and excellence has set them apart as a leader in the plumbing industry.The Teflon Tape Stainless Steel Fittings offered by the company have been designed to meet the highest standards of quality and performance. Each fitting undergoes rigorous testing to ensure that it meets the company's strict quality control measures before being released to the market. This attention to detail and commitment to excellence has earned the company a reputation for delivering products that exceed customer expectations.One of the key advantages of Teflon Tape Stainless Steel Fittings is their versatility. These fittings can be used in a wide range of plumbing applications, from residential to commercial settings. Whether it's for installing pipes in a new construction project or replacing old fittings in an existing system, Teflon Tape Stainless Steel Fittings offer a reliable solution that can withstand the test of time.In addition to their durability and reliability, Teflon Tape Stainless Steel Fittings are also easy to install, making them a favorite among plumbing professionals. Their simple yet effective design allows for quick and hassle-free installation, saving both time and resources on the job.Furthermore, the company's dedication to sustainability has also played a significant role in the development of Teflon Tape Stainless Steel Fittings. By using high-quality materials that are built to last, the company is reducing the need for frequent replacements, thus minimizing waste and contributing to a more sustainable future.With their track record of excellence and commitment to innovation, the introduction of Teflon Tape Stainless Steel Fittings by the company marks a significant milestone in the plumbing industry. These fittings have set a new standard for performance and reliability, offering a solution that delivers peace of mind to plumbing professionals and users alike.In conclusion, Teflon Tape Stainless Steel Fittings have redefined the plumbing industry with their unmatched durability, reliability, and performance. The company's commitment to excellence and innovation has led to the development of a product that has quickly become a favorite among plumbing professionals. As the demand for high-quality plumbing products continues to grow, Teflon Tape Stainless Steel Fittings are well-positioned to lead the way into a future where performance and sustainability go hand in hand.

Amber Glass Reagent Bottles: A Must-Have for Laboratory Use

Reagent Bottle Amber Glass: The Ideal Solution for Chemical Storage and ProtectionChemical storage and protection are essential aspects of the laboratory setting, and the choice of reagent bottles plays a crucial role in ensuring the safety and integrity of the substances being stored. With this in mind, a leading supplier in the laboratory equipment industry has introduced a new line of high-quality reagent bottles - the Reagent Bottle Amber Glass.This innovative product line is designed to provide a reliable and safe storage solution for a wide range of chemicals and laboratory substances. The amber glass material offers protection against harmful UV rays, making it ideal for light-sensitive chemicals that can degrade when exposed to light. Additionally, the high-quality glass construction ensures durability and chemical resistance, providing a secure containment for a variety of reagents.The Reagent Bottle Amber Glass is available in a range of sizes, catering to the diverse needs of laboratory professionals. Whether it's a small-scale experiment or a large-scale chemical storage requirement, these bottles offer a versatile and reliable solution. The wide mouth design facilitates easy filling and pouring of substances, while the secure screw cap ensures a tight seal, preventing any leaks or contamination.In addition to its practical design, the Reagent Bottle Amber Glass is also a sustainable choice for laboratory applications. The durable glass material can be reused multiple times, reducing the need for single-use plastic bottles and minimizing the environmental impact of laboratory operations. This aligns with the company's commitment to sustainability and responsible manufacturing practices, making the Reagent Bottle Amber Glass a conscientious choice for environmentally-conscious laboratories.As a leading supplier in the laboratory equipment industry, {Company} has established a reputation for delivering high-quality products and exceptional customer service. With a focus on innovation and continuous improvement, the company has consistently introduced cutting-edge solutions that meet the evolving needs of laboratory professionals. The Reagent Bottle Amber Glass is a testament to this commitment, offering a reliable and versatile option for chemical storage and protection.{Company} understands the importance of quality and reliability in laboratory equipment, and the Reagent Bottle Amber Glass reflects these core values. Through rigorous testing and quality control measures, the company ensures that each bottle meets the highest standards of performance and safety. Furthermore, the company's dedicated team of experts is readily available to provide guidance and support, assisting customers in selecting the most suitable products for their specific requirements.With the introduction of the Reagent Bottle Amber Glass, {Company} reinforces its position as a trusted partner for laboratory professionals, providing them with the tools they need to conduct their work safely and effectively. The company's unwavering dedication to quality, innovation, and customer satisfaction sets it apart in the industry, earning the trust and loyalty of customers worldwide.In conclusion, the Reagent Bottle Amber Glass represents a superior solution for chemical storage and protection in laboratory settings. With its durable construction, UV protection, and sustainable design, this product line offers a reliable and environmentally-friendly option for storing a wide range of reagents. Paired with {Company}'s commitment to excellence, the Reagent Bottle Amber Glass stands as a testament to the company's dedication to meeting the diverse needs of laboratory professionals.

High-Quality PTFE Dip Pipe for Industrial Applications

PTFE Dip Pipe Enhances Chemical Processing EfficiencyChemical processing industries often face challenges related to the containment and transportation of corrosive and hazardous substances. To address these challenges, [Company Name] offers a specialized solution in the form of PTFE dip pipes, which provide exceptional resistance to corrosion and high temperatures, making them ideal for a wide range of chemical applications.[Company Name] is a leading manufacturer of high-performance industrial solutions, specializing in the production of corrosion-resistant components for various industries such as chemical processing, pharmaceuticals, and petrochemicals. With a strong focus on innovation and quality, the company has gained a reputation for delivering reliable and durable products that meet the stringent requirements of modern industrial operations.The PTFE dip pipes offered by [Company Name] are designed to be used in chemical processing equipment such as reactors, tanks, and vessels, where they play a crucial role in the safe and efficient transportation of corrosive liquids and gases. The unique properties of PTFE, including its non-stick surface and resistance to chemicals, make it an ideal material for dip pipes, ensuring the integrity of the equipment and the safety of the personnel involved in the operation.One of the key advantages of PTFE dip pipes is their ability to withstand a wide range of temperatures, from cryogenic to high heat conditions, without experiencing any degradation in performance. This makes them suitable for handling a variety of chemical substances at different processing stages, contributing to the overall efficiency and productivity of the operation.Moreover, the non-stick nature of PTFE ensures that the dip pipes remain free from the build-up of deposits and contaminants, minimizing the risk of blockages and ensuring a smooth and continuous flow of materials. This not only enhances the performance of the processing equipment but also reduces the need for frequent maintenance and cleaning, leading to cost savings and improved operational uptime.The chemical resistance of PTFE dip pipes also makes them highly durable and long-lasting, even when exposed to aggressive substances such as acids, alkalis, and solvents. This reliability in the face of harsh operating conditions is essential for maintaining the safety and integrity of the chemical processing equipment, as well as meeting the regulatory standards for handling hazardous materials.Furthermore, [Company Name] offers customized solutions for PTFE dip pipes, tailored to meet the specific requirements of individual chemical processing applications. This includes the ability to design dip pipes in various lengths, diameters, and configurations, ensuring that they integrate seamlessly with the existing equipment and process requirements.In addition to their exceptional performance characteristics, PTFE dip pipes from [Company Name] are manufactured to the highest quality standards, utilizing advanced production techniques and rigorous quality control measures. This ensures that the end product meets the company's commitment to excellence and reliability, providing customers with a solution they can trust for their critical operational needs.As a responsible and customer-focused manufacturer, [Company Name] also provides comprehensive technical support and guidance to help customers select the most suitable PTFE dip pipe for their specific application. This includes expert advice on material compatibility, installation procedures, and maintenance best practices, ensuring that customers can maximize the value and performance of their investment.With the introduction of PTFE dip pipes, [Company Name] continues to demonstrate its commitment to delivering innovative and effective solutions for the chemical processing industry, offering a reliable and sustainable option for the safe and efficient handling of corrosive substances. By leveraging the unique properties of PTFE, the company is poised to make a positive impact on the operations of chemical processing facilities, helping them meet their production goals while maintaining the highest standards of safety and environmental responsibility.