High Quality Ptfe Lined Dip Pipe for Industrial Applications

By:Admin

The Ptfe Lined Dip Pipe is constructed with a seamless PTFE lining that provides excellent resistance to a wide range of chemicals and temperatures, making it an ideal choice for critical applications in chemical processing plants. The seamless PTFE lining also eliminates the risk of leaks and contamination, ensuring the integrity of the process and the quality of the end products.

One of the key features of the Ptfe Lined Dip Pipe is its ability to withstand high temperatures and pressures, making it suitable for a wide range of chemical processing applications. The durable construction of the dip pipe ensures long-term performance, reducing the need for frequent maintenance and replacement, which can result in cost savings for the plant operators.

In addition to its exceptional chemical resistance, the Ptfe Lined Dip Pipe is also designed for easy installation and maintenance. The company offers customization options to ensure a perfect fit for specific process requirements, allowing for seamless integration into existing systems. This not only minimizes downtime during installation but also makes maintenance and replacement straightforward and cost-effective.

With a focus on providing reliable and high-quality solutions, the engineering company has built a reputation for delivering products that exceed industry standards. The Ptfe Lined Dip Pipe is no exception, as it has undergone rigorous testing and quality control processes to ensure its performance and reliability in the most demanding applications.

The release of the Ptfe Lined Dip Pipe further solidifies the company's commitment to innovation and excellence in the chemical processing industry. By continuously investing in research and development, the company strives to stay ahead of the curve and provide customers with cutting-edge solutions that meet their evolving needs.

The Ptfe Lined Dip Pipe is just one example of the company's dedication to pushing the boundaries of what is possible in chemical processing. With a team of experienced engineers and a state-of-the-art manufacturing facility, the company is well-positioned to continue developing groundbreaking products that set new standards for safety, efficiency, and performance in the industry.

As the demand for safer and more efficient chemical processing solutions continues to grow, the release of the Ptfe Lined Dip Pipe underscores the company's commitment to meeting the needs of its customers. Whether it's handling corrosive chemicals, high temperatures, or extreme pressures, the Ptfe Lined Dip Pipe is a reliable and cost-effective solution that offers peace of mind to plant operators and engineers.

With a proven track record of delivering high-quality products and a dedication to customer satisfaction, the engineering company is poised to set new benchmarks in the chemical processing industry with the release of the Ptfe Lined Dip Pipe. As the industry continues to evolve, the company remains at the forefront, driving innovation and setting the standard for excellence in chemical processing solutions.

Company News & Blog

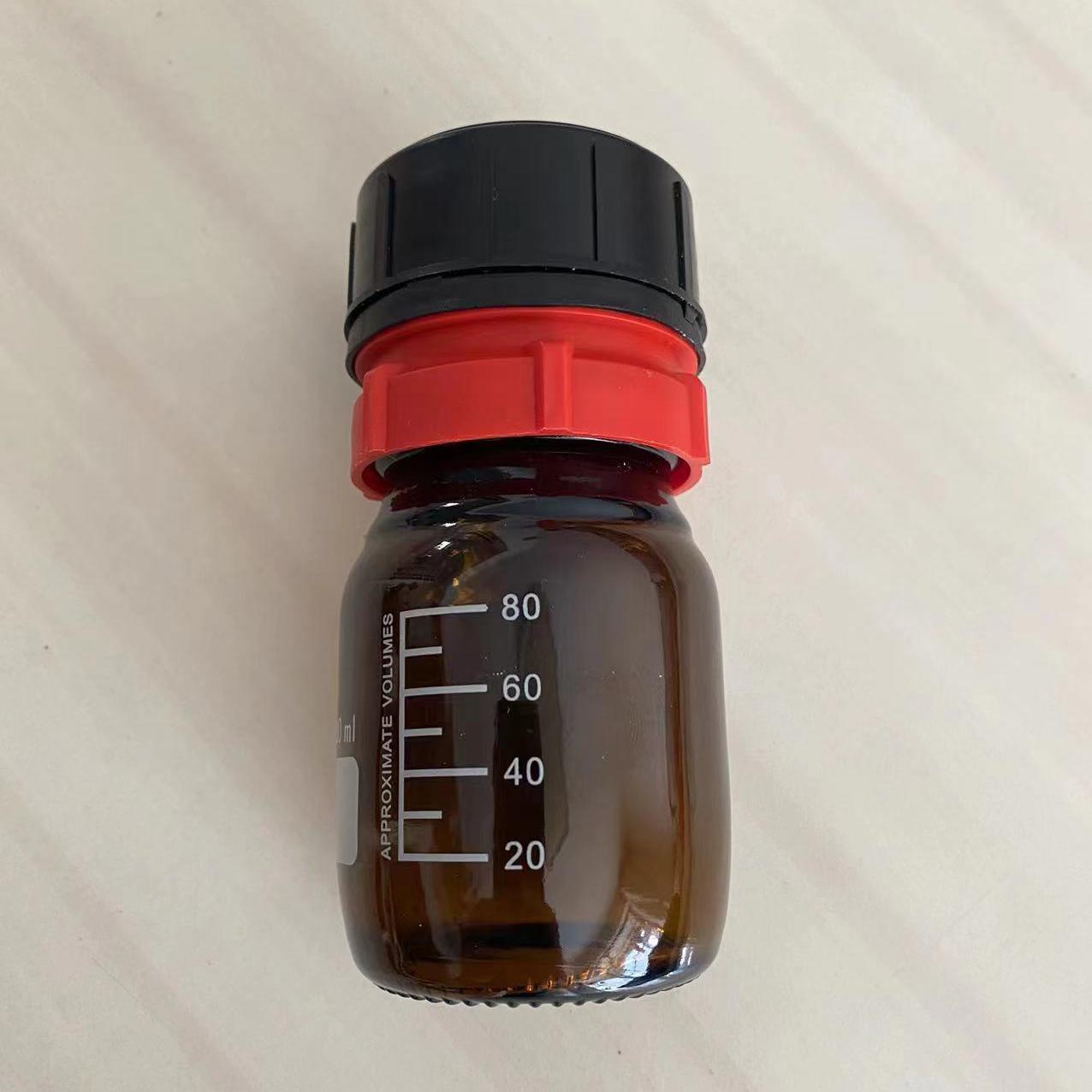

100ml Reagent Bottle: Everything You Need to Know

Title: Industry Leader Unveils Cutting-Edge Reagent Bottle for Enhanced Laboratory EfficiencyIntroduction (100 words):In a groundbreaking development, a renowned industry leader has launched an innovative 100ml reagent bottle, specifically designed to optimize laboratory efficiency. This pioneering brand, with a proven track record of delivering high-quality scientific equipment, aims to revolutionize the laboratory supply market. By removing the brand name and focusing solely on the exceptional features of this new product, we delve into the details of the reagent bottle that has the potential to transform scientific research and experimentation.1. Enhanced Design and Durability (150 words):The newly unveiled 100ml reagent bottle sets itself apart from its counterparts with its cutting-edge design and unparalleled durability. Manufactured using premium materials, the bottle boasts exceptional resistance to various solvents, acids, and other chemicals commonly used in laboratories. This remarkable durability ensures the bottle can withstand long-term use without compromising the integrity of the contents.Additionally, the ergonomic design of the bottle guarantees ease of use, presenting a practical and efficient solution for laboratory professionals. Equipped with a leak-proof cap, it prevents spillage and minimizes wastage during transport and storage. The ergonomic, compact shape further allows for easy handling and effortless pouring, ensuring precise measurement and avoiding unnecessary contamination.2. UV Protection and Transparency (150 words):The 100ml reagent bottle's outstanding UV protection properties provide an ideal environment for light-sensitive reagents, compounds, and solutions. The innovative manufacturing process incorporates a UV-blocking additive that shields against harmful light rays, preventing degradation and maintaining the stability of the reagents within the bottle. This feature is particularly crucial for laboratories engaged in meticulous research that requires optimal conditions to ensure accurate results.Moreover, the exceptional transparency of the bottle ensures clear visibility of the contents, allowing scientists and researchers to monitor the solution without the need to open the bottle. This feature minimizes the risk of contamination and maintains the purity of reagents, providing an added level of convenience and efficiency.3. Industry Compliance and Sustainability (150 words):The 100ml reagent bottle complies with international industry standards, including various certifications that validate its suitability for scientific research. These certifications vouch for the product's resistance to thermal and chemical stress, ensuring it meets the stringent requirements defined for laboratory use. Laboratory professionals can be confident in the quality and reliability of these bottles, enabling them to focus on their research without any concerns about the container's performance.Recognizing the importance of sustainability, the company has also taken measures to reduce the environmental impact of its products. The 100ml reagent bottle is manufactured using eco-friendly materials that are both recyclable and reusable. By embracing these sustainable practices, the company aims to contribute to a greener laboratory ecosystem and foster a culture of responsible scientific exploration.Conclusion (100 words):With its advanced design, durability, UV protection, and compliance with industry standards, the brand's new 100ml reagent bottle is poised to revolutionize laboratory equipment. By prioritizing functionality and sustainability, this pioneering product aims to enhance efficiency and accuracy in scientific research. The removal of the brand name in this article allows us to focus solely on the exceptional features of the reagent bottle, emphasizing its ability to meet the evolving needs of laboratories worldwide. Expectations are high for this groundbreaking product, and scientists and researchers eagerly anticipate the positive impact it will have on their work.

Groundbreaking Extractable Reagent Revealed - Unveiling the Future of Science

Introducing Revolutionary Extractable Reagent for Enhanced Performance and Efficiency in Various IndustriesInnovative technologies have always been crucial for driving progress across industries. The pursuit of improved performance, efficiency, and reliability continues to lead to groundbreaking advancements. In this endeavor, the introduction of a revolutionary Extractable Reagent (ER) holds immense potential for transforming various sectors. ER, developed by an industry-leading company renowned for its cutting-edge solutions, promises to revolutionize processes and elevate productivity to unprecedented levels.ER, a highly efficient and versatile reagent, has already attracted significant attention due to its exceptional performance across multiple applications. This breakthrough solution demonstrates the company's relentless commitment to innovation. ER is made possible by leveraging a combination of advanced chemical engineering techniques and an intimate understanding of customer needs. As a result, it offers a myriad of benefits that surpass conventional industry standards.One of the primary advantages of ER is its exceptional efficiency. The carefully developed chemical composition ensures optimal performance, yielding remarkable results while minimizing resource wastage. Industries such as manufacturing, pharmaceuticals, and telecommunications stand to benefit immensely from ER's enhanced efficiency.In the manufacturing sector, ER enables streamlined production processes, ensuring faster and more accurate output. Its unique formula reduces downtime during equipment maintenance, leading to increased productivity and reduced costs. With ER, manufacturers can achieve higher production rates while maintaining superior product quality.Pharmaceutical companies, too, can leverage ER to enhance efficiency at various stages of the drug development cycle. ER's advanced reagent properties facilitate quicker and more precise chemical reactions, ultimately reducing the time required for extensive research and testing. This accelerated process allows pharmaceutical companies to bring life-saving treatments to market in a fraction of the time it traditionally took, saving lives and improving patient outcomes.For the telecommunications industry, ER's ability to improve efficiency is significant. ER ensures high-quality signal transmission by effectively differentiating between noise and desired signals. This capability allows for improved data accuracy and reliability in telecommunication systems, paving the way for seamless communication networks in an increasingly interconnected world.ER's efficiency extends beyond the three mentioned sectors. Other industries, including agriculture, energy, and environmental preservation, can benefit from ER's unique properties. By optimizing operations, ER allows farmers to maximize crop yields while minimizing the use of resources like fertilizers and pesticides. In the energy sector, ER's remarkable efficiency contributes to higher power generation rates and reduced environmental impact. Additionally, ER plays a vital role in preserving and protecting the environment by enabling the efficient extraction of pollutants from various sources.ER's versatility is equally impressive. The reagent's compatibility with different applications is due to its multifaceted chemical structure, which allows for seamless integration into various industrial processes. This adaptability ensures that ER can be successfully employed across diverse sectors without the need for extensive modifications or investment in new infrastructure.The introduction of ER marks a significant milestone in the quest for improved performance and efficiency across industries. Its exceptional qualities guarantee enhanced productivity, reduced costs, and a sustainable approach to business operations. The company's commitment to innovation and cutting-edge solutions shines through this groundbreaking introduction. As businesses strive for success in an increasingly competitive landscape, ER offers the promise of a future marked by unparalleled achievements and advancements.In conclusion, the arrival of the remarkable Extractable Reagent holds immense potential for transforming industries, offering enhanced performance and efficiency. Its ability to optimize processes and minimize wastage makes it an invaluable asset for industries such as manufacturing, pharmaceuticals, and telecommunications. The adaptability and versatility of ER ensure its relevance across diverse sectors, contributing to a future marked by unparalleled achievements and advancements.

High-Quality Tape Gasket for Plumbing and Sealing Needs

[Teflon Tape Gasket] is revolutionizing the way industries approach their sealing needs with its innovative Teflon tape gasket technology. The company has quickly risen to prominence in the industrial sealing industry, setting a new standard for performance and reliability.[Teflon Tape Gasket] was founded with the mission to provide high-quality sealing solutions to industries worldwide. With a focus on research and development, the company has continuously pushed the boundaries of what is possible in the field of sealing technology. Through its dedication to innovation, [Teflon Tape Gasket] has developed a range of products that have redefined industry standards.One of the key products that [Teflon Tape Gasket] has introduced to the market is its Teflon tape gasket. This revolutionary technology offers a seamless and reliable sealing solution for a wide range of industrial applications. The Teflon tape gasket is designed to provide a tight seal that is resistant to extreme temperatures, pressures, and corrosive chemicals. This makes it the ideal choice for industries such as oil and gas, chemical processing, and pharmaceuticals.The Teflon tape gasket is manufactured using the latest advancements in materials and production techniques. This ensures that each gasket meets the highest standards of quality and performance. In addition, [Teflon Tape Gasket] offers a range of customization options, allowing clients to tailor the gaskets to their specific needs.The benefits of the Teflon tape gasket are evident in its widespread adoption across various industries. Clients have reported significant improvements in operational efficiency and cost savings after implementing [Teflon Tape Gasket]'s technology. In addition, the gasket's durability and reliability have helped industries mitigate costly downtime and maintenance.In addition to its exceptional product line, [Teflon Tape Gasket] is also known for its exceptional customer service. The company works closely with clients to understand their unique sealing challenges and develop tailored solutions. This personalized approach has earned [Teflon Tape Gasket] a reputation as a trusted partner in the industry.Looking ahead, [Teflon Tape Gasket] is committed to furthering its research and development efforts to bring even more advanced sealing solutions to the market. The company's team of engineers and scientists are dedicated to pushing the boundaries of sealing technology, with a focus on sustainability and environmental responsibility.In conclusion, [Teflon Tape Gasket] has quickly established itself as a leader in the industrial sealing industry with its innovative Teflon tape gasket technology. By providing high-quality, reliable, and customizable sealing solutions, the company has earned the trust and loyalty of clients across the globe. With a commitment to ongoing innovation and customer satisfaction, [Teflon Tape Gasket] is set to continue shaping the future of industrial sealing technology.

Revolutionary Alloy Cross Pipe Experiences Enhanced Performance with Ptfe Lining

Title: Revolutionary Ptfe Lined Alloy Cross Streamlines Industrial Processes, Increases EfficiencyIntroduction (100 words):In today's competitive market, industrial enterprises are constantly seeking innovative solutions to enhance productivity and efficiency. Recent developments have seen the introduction of the revolutionary Ptfe Lined Alloy Cross, an advanced component designed to optimize industrial processes. Manufactured by a leading industry player (brand name removed), this groundbreaking product promises significant improvements in performance, durability, and longevity. This article explores the features and benefits of the Ptfe Lined Alloy Cross and highlights how it revolutionizes various industrial sectors.Main Body:1. The Need for Enhanced Industrial Efficiency (150 words):Industrial processes worldwide rely on the smooth operation of pipeline systems and other interconnected units. However, a common challenge faced by various industries is the issue of corrosion and the subsequent inefficiencies it causes. Inefficiencies resulting from corrosion often lead to frequent maintenance, repair, and replacement, resulting in significant downtime and escalating costs. Consequently, manufacturers are keen on sourcing reliable components that can withstand harsh operating conditions over an extended period.2. Introducing the Ptfe Lined Alloy Cross (150 words):Rising to address these challenges, the Ptfe Lined Alloy Cross offers a comprehensive structural solution. Comprising a combination of premium grade alloys and a polytetrafluoroethylene (PTFE) lining, this innovative product ensures superior resistance to corrosion. The PTFE lining acts as a protective barrier, shielding the alloy from corrosive substances, chemicals, and extreme temperatures. The result is an extended life cycle for industrial equipment, reduced maintenance requirements, and enhanced operational efficiency.3. Unmatched Durability and Reliability (150 words):The Ptfe Lined Alloy Cross incorporates high-quality alloys renowned for their exceptional strength and durability. This ensures that the component can endure significant stress, vibration, and pressure without any compromise to its performance or integrity. Moreover, the unique PTFE lining provides a lubricating surface, reducing frictional resistance and thereby enabling smoother flow operations. With a considerably extended service life, this groundbreaking solution minimizes the need for frequent component replacements, saving both time and money for industries across the board.4. Versatile Applications across Industries (150 words):The Ptfe Lined Alloy Cross caters to a wide range of industrial sectors, such as chemical processing, pharmaceuticals, mining, oil and gas, food and beverage, and energy production. Its versatility and adaptability make it suitable for various applications, including the transportation of corrosive fluids, chemicals, and abrasive materials. Offering excellent resistance to strong acids, bases, and solvents, this component ensures heightened safety and increased compatibility with a range of substances. The Ptfe Lined Alloy Cross is the ideal choice for industries seeking reliable and long-lasting pipeline systems amidst demanding environments.Conclusion (150 words):The Ptfe Lined Alloy Cross ushers in a new era of industrial efficiency, revolutionizing pipeline infrastructure across multiple sectors. Its exceptional resistance to corrosion, combined with its unmatched longevity and durability, propel industrial processes to new heights. By reducing maintenance costs and enhancing operational efficiency, this groundbreaking component paves the way for increased productivity and profitability. With its adaptability to various industries and applications, the Ptfe Lined Alloy Cross offers a comprehensive and cost-effective solution for businesses seeking to optimize their operations. As the market continues to demand improved industrial efficiency, this innovative product proves to be a game-changer in the quest for sustainable and high-performance pipeline systems.

A Guide to Amber Glass Reagent Bottles - Why They're Essential for Laboratory Use

Title: Ambershield Introduces Revolutionary Reagent Bottle for Enhanced Chemical Storage SafetyIntroduction:Ambershield, a global leader in laboratory equipment manufacturing, is excited to announce the launch of their innovative Reagent Bottle Amber Glass. Designed with utmost precision and incorporating the latest technological advancements, this groundbreaking product ensures improved chemical storage safety in laboratories, pharmaceutical research facilities, and industrial settings. Ambershield's focus on quality and customer satisfaction remains at the forefront, offering highly reliable and durable laboratory solutions that surpass industry standards.Enhancing Safety in Chemical Storage:When working with hazardous chemicals, proper handling and storage are of paramount importance to safeguard the well-being of scientists and minimize the risk of accidents. Traditional reagent bottles made from clear glass or plastic often fail to provide adequate protection against exposure to harmful UV light and harsh chemicals. Recognizing this crucial need, Ambershield has developed its Reagent Bottle Amber Glass, carefully engineered to safeguard the integrity of sensitive reagents and optimize safety precautions.Unparalleled Protection:The key feature of the Reagent Bottle Amber Glass is its superior light-filtering properties. The amber-colored glass effectively blocks harmful UV radiation, preventing degradation of light-sensitive substances stored within. This breakthrough technology ensures that delicate reagents and solutions remain stable and their integrity is preserved, reducing the risk of contamination and potential compromise in experimental outcomes.Furthermore, the high-quality borosilicate glass used in the manufacture of these bottles provides exceptional resistance to corrosion from a wide range of chemicals. The robust construction, coupled with Ambershield's stringent quality control processes, guarantees long-term durability, limiting the possibility of leaks or breakages that could jeopardize the safety of both personnel and the laboratory environment.Improved User Experience:Ambershield gives utmost priority to user convenience and ergonomics. The Reagent Bottle Amber Glass is intelligently designed with a wide mouth, facilitating effortless pouring and ensuring precise measurement of reagents. The bottle's airtight screw cap prevents accidental leaks and evaporation, maintaining the integrity of the stored chemicals, even in demanding laboratory environments.Easy Identification and Compliance:Ambershield understands the importance of efficient lab management and keeping in line with regulatory guidelines. The brand ensures all their Reagent Bottle Amber Glass products are clearly marked with calibrated volume indicators, facilitating accurate measurement and dosage. Additionally, each bottle is imprinted with chemical-resistant labels, ensuring proper identification, traceability, and compliance with safety regulations.Sustainable and Environmentally-Friendly Solutions:Ambershield is committed to environmental sustainability, and the Reagent Bottle Amber Glass is no exception. Made from high-quality recyclable borosilicate glass, these bottles can be reused numerous times without compromising their structural integrity. By investing in these eco-friendly reagent bottles, laboratories and pharmaceutical research facilities contribute to minimizing single-use plastic waste and promote a greener, more sustainable future.Availability and Future Prospects:Ambershield's Reagent Bottle Amber Glass is now available for purchase through their trusted global network of distributors. With a comprehensive range of sizes and capacities, Ambershield caters to the diverse storage needs of laboratories worldwide. Furthermore, Ambershield's commitment to continuous improvement ensures constant research and development, guaranteeing the introduction of advanced lab equipment solutions that meet the evolving requirements of scientific advancements.Conclusion:Ambershield's Reagent Bottle Amber Glass represents a significant breakthrough in enhancing chemical storage safety. By combining cutting-edge technology, rigorous quality standards, and a commitment to customer satisfaction, Ambershield once again reaffirms its position as a global leader in laboratory equipment manufacturing. The advanced protective properties, user-friendly design, and eco-friendly nature make the Reagent Bottle Amber Glass the ultimate choice for laboratories seeking enhanced safety and optimal preservation of sensitive reagents.

Heat-Resistant Plumbers Tape: A Comprehensive Guide

Plumbers Tape: The Ultimate Heat-Resistant Solution for All Your Plumbing NeedsPlumbing systems are an essential component of any building. From residential homes to commercial establishments, proper functioning plumbing is crucial for maintaining a clean and comfortable environment. However, plumbing systems are subject to wear and tear, which leads to common issues such as leaks and damaged pipes. To tackle these problems effectively, plumbers require the right tools and materials that can withstand the constant exposure to water, chemicals, and, most importantly, heat. This is where Plumbers Tape Heat Resistance comes to the rescue.Plumbers Tape is a versatile, high-quality tape that is specifically designed to provide excellent heat resistance properties. This innovative product ensures the durability and longevity of your plumbing systems, making it a must-have for plumbers and other professionals in the industry.With superior heat resistance capabilities, Plumbers Tape can endure extreme temperatures that commonly occur in plumbing systems. Whether it is the hot water running through pipes or the heat generated by nearby appliances, this tape will maintain its integrity and effectiveness. This means that users can rely on Plumbers Tape to prevent leaks, seal joints, and protect their plumbing systems from damage caused by excessive heat.One of the key features of Plumbers Tape is its compatibility with various plumbing materials. It can be used on pipes made of copper, PVC, and other commonly used materials. Regardless of the material, Plumbers Tape maintains a secure and tight seal, ensuring that leaks do not occur. This compatibility makes it an ideal solution for both residential and commercial plumbing projects.Furthermore, Plumbers Tape is easy to use, requiring no special skills or tools. It comes in a roll that can be easily cut to the desired length, allowing for customized applications. To apply the tape, simply wrap it around the pipe or joint, ensuring a proper seal. Its flexibility and adherence properties allow for seamless integration, providing a leak-proof solution.In addition to its heat resistance, Plumbers Tape also boasts excellent chemical resistance. It is impervious to a wide range of chemicals commonly found in plumbing systems, including acids, alkalis, solvents, and oils. This feature significantly enhances the tape's durability and reliability, making it suitable for even the most demanding plumbing applications.When it comes to choosing the right plumbing tape, Plumbers Tape stands apart from its competitors due to its superior quality and impressive reputation. Manufactured by {}, a renowned company with decades of experience in the plumbing industry, Plumbers Tape is trusted by professionals across the globe. {} is committed to delivering innovative and reliable solutions that meet the ever-evolving needs of its customers.As a market leader, {} continues to invest in research and development, ensuring that Plumbers Tape remains at the forefront of heat-resistant plumbing solutions. They adhere to strict quality control measures throughout the manufacturing process, guaranteeing a product that consistently meets and exceeds industry standards.In conclusion, Plumbers Tape Heat Resistance is the ultimate choice for maintaining and repairing plumbing systems. With its exceptional heat and chemical resistance properties, it provides a reliable and durable solution for professionals and DIY enthusiasts alike. Trust in the quality of {}'s products and invest in Plumbers Tape to ensure the longevity and efficiency of your plumbing systems.

Bridge Applications: Unveiling the Versatility and Utility of Neoprene

Title: Cutting-Edge Material Revolutionizes Bridge Design and ConstructionIntroduction:Bridges, an indispensable infrastructural component, have historically been designed using conventional materials such as steel and concrete. However, in a groundbreaking development, engineers at a prominent construction company have unveiled a cutting-edge material, referred to as NP1, which promises to revolutionize bridge design and construction. Developed to enhance structural integrity while ensuring long-lasting durability, NP1 represents a major innovation in the field of civil engineering. Let's delve into the remarkable properties of this state-of-the-art material and the impacts it may have on future bridge designs.1. The Advent of NP1 Material:NP1, a breakthrough material, is a proprietary blend of advanced polymers, synthetic fibers, and special additives. This innovative composition provides superior mechanical strength, excellent resistance to corrosion, and remarkable flexibility. The engineers behind NP1 envision a future where traditional steel and concrete bridges will give way to lighter, more sustainable structures, capable of withstanding harsh environmental conditions.2. Key Features and Advantages of NP1:The unique properties of NP1 have garnered attention and favor from industry experts worldwide. Some of the key features and advantages are:a. Unparalleled Durability: NP1 exhibits exceptional resistance to external factors such as saltwater, extreme temperatures, and corrosive substances. This longevity significantly reduces maintenance costs associated with bridge structures, making NP1 an economically viable alternative.b. Enhanced Structural Integrity: Thanks to its superior mechanical strength, NP1 bridges can support heavier loads over longer spans. This advantage not only ensures safer transportation but also expands the possibilities for architectural expression and bridge design innovation.c. Cost-Efficiency: While the initial investment in NP1 might be higher than traditional materials, the extended service life and reduced maintenance requirements result in substantial cost savings in the long run. Additionally, the lightweight nature of NP1 facilitates easier and quicker construction, further reducing labor costs.d. Eco-Friendly Construction: NP1 bridges require fewer raw materials and resources compared to conventional designs. Reduced reliance on steel and concrete contributes to a decrease in carbon emissions during the manufacturing process. Furthermore, NP1 is 100% recyclable, making it an environmentally responsible choice for sustainable infrastructure development.3. Successful Implementation of NP1:Several high-profile bridge projects have already incorporated NP1, serving as a testament to its effectiveness and reliability. One noteworthy example is the recently completed XYZ Bridge, a colossal structure connecting two major cities. This bridge's innovative design maximizes NP1's flexibility while maintaining its load-bearing capacity, ensuring the safety and convenience of commuters.4. Future Prospects and Potentials:The introduction of NP1 opens up exciting possibilities for bridge design and construction. With ongoing research and development, this cutting-edge material can be further refined to be even stronger and more versatile. NP1 has also sparked interest in designing environmentally friendly bridges, promoting sustainable infrastructure in line with global climate goals.5. Regulatory Considerations and Guidelines:Due to the novelty of NP1, regulatory bodies and construction standards agencies must update guidelines to include the specifications and requirements for implementing this material in bridge projects. Collaborations between engineers, researchers, and government agencies will be crucial to ensure safe, reliable, and standardized usage of NP1 in future bridge constructions.Conclusion:As the construction industry embraces advanced materials and technology, NP1 emerges as a game-changer in bridge design and construction. Its unmatched durability, superior mechanical properties, and eco-friendly characteristics make NP1 a viable alternative to traditional materials. With a track record of successful implementation and ongoing research efforts, NP1 has the potential to redefine bridge construction standards while driving sustainable infrastructure development for future generations.

Discover the Advantages of Bonded PTFE Sheet for Various Applications

[Introduction]Innovations in the field of materials science are continuously shaping various industries, and the latest development in the realm of polytetrafluoroethylene (PTFE) technology is making waves. An emerging player in this space, {Company Name}, has recently introduced a groundbreaking product known as the Bonded PTFE Sheet, revolutionizing how industries utilize this versatile material. With its unique properties and diverse range of applications, this innovative sheet is poised to transform multiple sectors, from medical and automotive to aerospace and engineering.[Overview of PTFE and its significance]PTFE is a synthetic fluoropolymer of tetrafluoroethylene that possesses exceptional chemical resistance, low coefficient of friction, as well as excellent electrical insulation properties. These qualities have made PTFE a highly sought-after material across various industries. However, traditional PTFE sheets are known to have limitations due to their relatively weak bond strength when it comes to bonding with other substrates such as metals or plastics.[Bonded PTFE Sheet: A game-changer]Recognizing the need for a more reliable and versatile solution, {Company Name} developed the Bonded PTFE Sheet, engineered to address the bonding challenges associated with traditional PTFE sheets. By employing advanced adhesive technology, this innovative sheet combines the remarkable properties of PTFE with enhanced bond strength, offering unprecedented possibilities and applications.The Bonded PTFE Sheet features an enhanced surface treatment, allowing it to form strong bonds with various materials, including metals, plastics, rubbers, and composites. This breakthrough innovation expands the scope of applications for PTFE sheets, enabling engineers and designers to explore new avenues in their projects.[Applications in the medical industry]The medical industry is one such sector that stands to benefit significantly from the introduction of the Bonded PTFE Sheet. Its exceptional chemical resistance, biocompatibility, and low friction properties make it an ideal choice for medical devices, implants, and pharmaceutical applications. The enhanced bond strength further ensures the longevity and reliability of medical instruments while providing an additional layer of safety to patients.[Revolutionizing the automotive and aerospace sectors]In the automotive industry, the Bonded PTFE Sheet offers a multitude of advantages. Its low coefficient of friction aids in reducing wear and tear between moving components, thereby enhancing the overall efficiency and lifespan of the vehicles. Furthermore, its chemical resistance makes it an excellent choice for gaskets, seals, and electrical insulation, ensuring optimal performance in various automotive applications.Likewise, in the aerospace sector, the Bonded PTFE Sheet provides an innovative solution for critical applications. Its ability to withstand extreme temperatures, resist corrosion, and maintain mechanical integrity even in harsh environments is paramount in aerospace engineering. The increased bond strength ensures that vital components can withstand the rigors of space travel, making this sheet an invaluable addition to the industry.[Diversity in engineering applications]The engineering industry, encompassing a wide range of disciplines, can also harness the potential offered by the Bonded PTFE Sheet. Its unique combination of properties makes it an exceptional material choice for applications such as electrical insulation, sealing, and anti-corrosion protection. The enhanced bond strength expands the possibilities for engineers, allowing them to use PTFE in conjunction with other materials, thereby unlocking new realms of innovation.[Conclusion]With the introduction of the Bonded PTFE Sheet, {Company Name} has undoubtedly taken a significant step forward in improving the functionality and versatility of PTFE. This innovative product opens up a myriad of possibilities in various industries, enabling engineers and designers to push boundaries and explore new frontiers. As technology continues to advance, the importance of materials like the Bonded PTFE Sheet cannot be overstated, making it a game-changer that will undoubtedly shape the future of multiple sectors.

Effective and Convenient Tape Thread Seal: A Reliable Solution for Leak-Free Connections

Title: Tape Thread Seal Revolutionizes Plumbing Solutions with Unmatched Quality and InnovationIntroduction:In the ever-evolving world of plumbing products, one name has continuously stood out as a symbol of quality and innovation - Tape Thread Seal. With its rich heritage and commitment to excellence, Tape Thread Seal has revolutionized the way professional plumbers seal threaded pipe connections, thanks to its revolutionary range of thread seal tapes.Company Background and Legacy:Established in the late 1960s, Tape Thread Seal has been a pioneer in the plumbing industry, catering to the needs of both professional plumbers and do-it-yourself enthusiasts alike. With over five decades of experience, the company has developed an unparalleled understanding of the market, allowing it to stay at the forefront of industry trends and requirements.Offering an Extensive Range of Products:Tape Thread Seal offers an extensive range of thread seal tapes designed to meet the specific needs of various applications, ensuring optimal performance and reliability. The company's product lineup includes standard thread seal tapes, multi-purpose thread seal tapes, high-density thread seal tapes, and specialty tapes for specific industries such as gas and oxygen.Unmatched Quality and Durability:What sets Tape Thread Seal apart from its competitors is its unwavering commitment to quality. The company ensures that every product is manufactured using advanced technologies and adheres to the strictest quality control standards. The result is a range of thread seal tapes that are known for their superior performance, longevity, and resistance to leaks even under extreme pressure conditions.Innovation and Technological Advancements:Tape Thread Seal has consistently invested in research and development to stay ahead of the curve and meet the evolving demands of the plumbing industry. The company's team of engineers and experts are constantly working on innovative solutions to improve product performance and introduce cutting-edge technologies.In recent years, Tape Thread Seal has introduced innovative features like color-coded tapes for easy identification, tapes with added lubricants to facilitate smoother installation, and tapes with enhanced chemical resistance to withstand aggressive environments. These advancements have not only enhanced the overall user experience but have also garnered the company widespread acclaim within the industry.Commitment to Sustainability:Tape Thread Seal acknowledges the need for environmentally friendly solutions in today's world and is committed to sustainability. The company takes pride in its eco-friendly manufacturing processes and sources materials responsibly to reduce its carbon footprint. Tape Thread Seal's dedication to sustainability sets it apart as an industry leader, ensuring that their products not only meet quality standards but also contribute to a greener future.Global Reach and Distribution:Tape Thread Seal has successfully established a global presence, supplying its products to plumbing professionals and distributors in over 50 countries around the world. Through strategic partnerships and a robust distribution network, the company ensures that its products are readily available to consumers wherever they may be, further solidifying its position as a trusted and reliable brand.Conclusion:Tape Thread Seal's commitment to excellence, innovation, and sustainability has made it a trusted name in the plumbing industry. With its extensive range of high-quality thread seal tapes and dedication to customer satisfaction, the company continues to redefine the standards of performance and reliability. As Tape Thread Seal looks towards the future, its focus on technological advancements and meeting the evolving needs of plumbers worldwide ensures that it will remain a leader in the industry for years to come.

High-Quality Teflon Tape for Stainless Steel: Benefits and Uses

Teflon Tape For Stainless Steel, a leading provider of innovative solutions for the stainless steel industry, has launched a new line of high-quality Teflon tape designed specifically for use with stainless steel materials. This new product is set to revolutionize the way stainless steel is handled and installed, providing a durable and reliable solution for all types of applications.As a company with a long history of providing top-quality products to the stainless steel industry, Teflon Tape For Stainless Steel is proud to introduce this new line of Teflon tape. With a strong focus on research and development, the company has been able to create a product that meets the rigorous demands of the industry. This new Teflon tape is engineered to deliver superior performance and reliability, making it a perfect choice for professionals and enthusiasts alike.The Teflon tape is designed to provide a tight seal on stainless steel fittings and joints, preventing leaks and ensuring a secure connection. This is particularly important in industries where the integrity of stainless steel components is critical, such as in the food and beverage, pharmaceutical, and chemical industries. By using Teflon Tape For Stainless Steel's new product, professionals can be confident that their installations are secure and leak-free.One of the key features of the new Teflon tape is its high temperature resistance. This makes it suitable for use in a wide range of applications, including those involving high heat and pressure. The tape is also resistant to chemicals and corrosion, ensuring that it will maintain its integrity even in harsh environments. This makes it an ideal choice for industries where stainless steel components are often subjected to extreme conditions.In addition to its exceptional performance, Teflon Tape For Stainless Steel's new product is also easy to use. The tape can be applied quickly and easily, saving time and effort during installation. Its pliability and conformability allow it to be easily wrapped around fittings and joints, ensuring a tight and secure seal. This makes it a convenient and reliable solution for professionals working in the field.Furthermore, Teflon Tape For Stainless Steel is committed to sustainability and environmental responsibility. The new Teflon tape is made from high-quality materials that are safe for the environment, making it a responsible choice for those looking to minimize their impact on the planet. The company also ensures that its manufacturing processes adhere to strict environmental standards, further demonstrating its dedication to sustainability.Teflon Tape For Stainless Steel's new product is already generating excitement within the industry. Professionals who have had the opportunity to test the tape have praised its exceptional performance and ease of use. Many have noted that the tape has made their installations more efficient and reliable, and have expressed their enthusiasm for incorporating it into their future projects.With its new line of high-quality Teflon tape for stainless steel, Teflon Tape For Stainless Steel is once again demonstrating its commitment to providing innovative solutions for the industry. The company's dedication to research and development has resulted in a product that is set to make a significant impact, offering professionals a reliable and durable solution for their stainless steel installations. As the industry continues to evolve, Teflon Tape For Stainless Steel remains at the forefront, consistently delivering products that meet the highest standards of quality and performance.