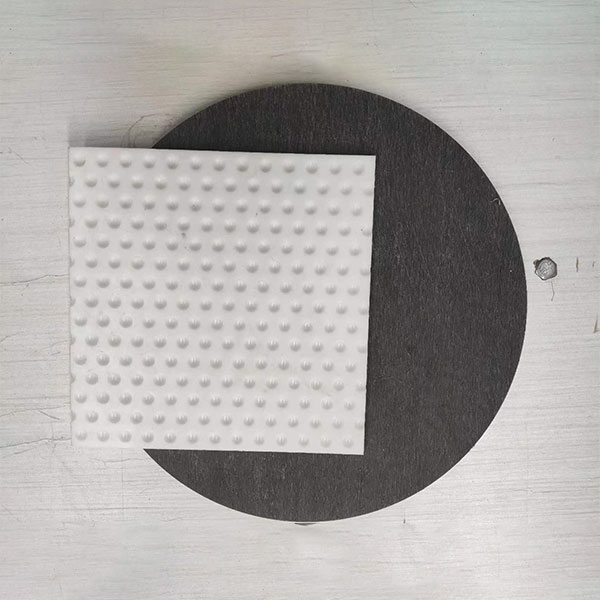

High-Quality UHMWPE Bridge Support Pad for Enhanced Stability

By:Admin

The company behind this groundbreaking product, [Company Name], has a proven track record of delivering high-quality engineering solutions for infrastructure projects. With a focus on innovation and sustainability, [Company Name] has established itself as a trusted partner for clients in the construction and engineering industry.

The Black UHMWPE Bridge Support Pad is the latest addition to [Company Name]'s extensive range of engineered products. Made from ultra-high molecular weight polyethylene (UHMWPE), the support pad is incredibly strong and durable, making it an ideal choice for supporting heavy loads and providing long-term stability for bridges. In addition to its impressive strength, the support pad is also resistant to corrosion, abrasion, and impact, ensuring that it can withstand the harshest environmental conditions.

One of the key advantages of the Black UHMWPE Bridge Support Pad is its versatility. Unlike traditional support methods, which often require custom fabrication and complex installation processes, the UHMWPE support pad can be easily customized and installed to fit the specific needs of any bridge project. This not only saves time and money during the construction process but also allows for greater flexibility and adaptability in bridge design and maintenance.

Furthermore, the UHMWPE material used in the support pad is environmentally friendly, making it a sustainable choice for bridge construction and maintenance. Its long lifespan and resistance to wear and tear mean that it can significantly reduce the need for frequent replacements and maintenance, minimizing the environmental impact of bridge projects.

In addition to its technical advantages, the Black UHMWPE Bridge Support Pad also offers cost savings for clients. Its durability and low maintenance requirements result in reduced long-term costs, while its ease of installation and customization can streamline construction processes and improve overall project efficiency. This makes it an attractive option for engineers and contractors looking to optimize their bridge projects without compromising on quality and safety.

The introduction of the Black UHMWPE Bridge Support Pad is a testament to [Company Name]'s commitment to innovation and excellence in the engineering industry. By continuously developing and introducing new and advanced products, [Company Name] is empowering its clients with the tools and solutions they need to tackle complex infrastructure challenges and achieve success in their projects.

As the demand for sustainable and high-performance infrastructure solutions continues to grow, the Black UHMWPE Bridge Support Pad is poised to make a significant impact on the construction and maintenance of bridges around the world. Its superior strength, durability, and versatility position it as a game-changer in the industry, offering a new standard for bridge support that is both effective and environmentally responsible.

With the Black UHMWPE Bridge Support Pad, [Company Name] is once again demonstrating its leadership in the engineering solutions market, and its ongoing commitment to delivering innovative, sustainable, and cost-effective products that meet the evolving needs of the industry. Clients can trust in the reliability and performance of this latest offering, knowing that it has been developed by a company with a proven track record of excellence and a dedication to driving positive change in the infrastructure sector.

Company News & Blog

High-Quality Teflon Tape for Industrial Use

Cooper Teflon Tape Leads the Industry with Innovative ProductsCooper Teflon Tape, a leading manufacturer of high-quality industrial sealing products, continues to assert its dominance in the industry with the introduction of innovative products that set new standards for performance and reliability. With a strong commitment to excellence and customer satisfaction, the company has firmly established itself as a trusted provider of Teflon tape solutions for a wide range of industrial applications.For over a decade, Cooper Teflon Tape has been at the forefront of advancing sealing technology, consistently delivering products that meet the evolving needs of its customers. The company's extensive experience and expertise in the field have enabled it to develop a comprehensive range of Teflon tape products that offer superior performance, durability, and versatility. From standard sealing applications to specialized uses in extreme environments, Cooper Teflon Tape has the right solution for every sealing challenge.One of the key factors that set Cooper Teflon Tape apart from its competitors is its unwavering commitment to innovation. The company continuously invests in research and development to stay ahead of the curve and bring cutting-edge solutions to the market. This dedication to innovation has led to the development of several groundbreaking products that have revolutionized the industry and raised the bar for performance and quality.In particular, Cooper Teflon Tape's latest product, which cannot be named, has generated significant excitement and interest among industry professionals. This innovative Teflon tape is engineered to deliver exceptional sealing performance in the most demanding applications, where traditional sealing materials may fall short. Its unique composition and superior design make it an ideal choice for sealing applications in harsh chemical environments, extreme temperatures, and high-pressure conditions.Furthermore, the new product boasts enhanced resistance to chemicals, corrosion, and abrasion, making it a reliable and long-lasting solution for a wide range of industrial sealing challenges. Its exceptional flexibility and conformability ensure a tight and secure seal, even on irregular or uneven surfaces, providing peace of mind to users and minimizing the risk of leaks and failures.As part of its commitment to providing comprehensive solutions, Cooper Teflon Tape offers customization options for its products, allowing customers to tailor sealing solutions to their specific requirements. Whether it's a unique size, thickness, or special additive, the company's team of experts works closely with customers to develop customized Teflon tape solutions that meet their exact needs and specifications.In addition to its innovative products, Cooper Teflon Tape is also known for its dedication to quality and consistency. The company maintains stringent quality control measures throughout the manufacturing process to ensure that every roll of Teflon tape meets the highest standards of excellence. This commitment to quality has earned Cooper Teflon Tape a stellar reputation for reliability and performance, making it the go-to choice for discerning professionals in various industries.Moreover, Cooper Teflon Tape prides itself on its responsive and customer-centric approach. The company's team of experienced professionals is always ready to provide expert guidance and support, helping customers find the best sealing solutions for their specific needs. With a focus on building long-term relationships and delivering exceptional value, Cooper Teflon Tape strives to be a trusted partner to its customers, offering not just products, but also reliable support and expertise.In conclusion, Cooper Teflon Tape's dedication to innovation, quality, and customer satisfaction has positioned it as a leader in the industry, setting new benchmarks for sealing performance and reliability. With its latest innovative product {} and a comprehensive range of Teflon tape solutions, the company continues to drive progress and provide exceptional value to its customers. As the industry evolves, Cooper Teflon Tape remains committed to staying ahead of the curve and delivering cutting-edge solutions that meet the evolving needs of its customers, ensuring that it remains at the forefront of the industry for years to come.

Revolutionary Alloy Cross Pipe Experiences Enhanced Performance with Ptfe Lining

Title: Revolutionary Ptfe Lined Alloy Cross Streamlines Industrial Processes, Increases EfficiencyIntroduction (100 words):In today's competitive market, industrial enterprises are constantly seeking innovative solutions to enhance productivity and efficiency. Recent developments have seen the introduction of the revolutionary Ptfe Lined Alloy Cross, an advanced component designed to optimize industrial processes. Manufactured by a leading industry player (brand name removed), this groundbreaking product promises significant improvements in performance, durability, and longevity. This article explores the features and benefits of the Ptfe Lined Alloy Cross and highlights how it revolutionizes various industrial sectors.Main Body:1. The Need for Enhanced Industrial Efficiency (150 words):Industrial processes worldwide rely on the smooth operation of pipeline systems and other interconnected units. However, a common challenge faced by various industries is the issue of corrosion and the subsequent inefficiencies it causes. Inefficiencies resulting from corrosion often lead to frequent maintenance, repair, and replacement, resulting in significant downtime and escalating costs. Consequently, manufacturers are keen on sourcing reliable components that can withstand harsh operating conditions over an extended period.2. Introducing the Ptfe Lined Alloy Cross (150 words):Rising to address these challenges, the Ptfe Lined Alloy Cross offers a comprehensive structural solution. Comprising a combination of premium grade alloys and a polytetrafluoroethylene (PTFE) lining, this innovative product ensures superior resistance to corrosion. The PTFE lining acts as a protective barrier, shielding the alloy from corrosive substances, chemicals, and extreme temperatures. The result is an extended life cycle for industrial equipment, reduced maintenance requirements, and enhanced operational efficiency.3. Unmatched Durability and Reliability (150 words):The Ptfe Lined Alloy Cross incorporates high-quality alloys renowned for their exceptional strength and durability. This ensures that the component can endure significant stress, vibration, and pressure without any compromise to its performance or integrity. Moreover, the unique PTFE lining provides a lubricating surface, reducing frictional resistance and thereby enabling smoother flow operations. With a considerably extended service life, this groundbreaking solution minimizes the need for frequent component replacements, saving both time and money for industries across the board.4. Versatile Applications across Industries (150 words):The Ptfe Lined Alloy Cross caters to a wide range of industrial sectors, such as chemical processing, pharmaceuticals, mining, oil and gas, food and beverage, and energy production. Its versatility and adaptability make it suitable for various applications, including the transportation of corrosive fluids, chemicals, and abrasive materials. Offering excellent resistance to strong acids, bases, and solvents, this component ensures heightened safety and increased compatibility with a range of substances. The Ptfe Lined Alloy Cross is the ideal choice for industries seeking reliable and long-lasting pipeline systems amidst demanding environments.Conclusion (150 words):The Ptfe Lined Alloy Cross ushers in a new era of industrial efficiency, revolutionizing pipeline infrastructure across multiple sectors. Its exceptional resistance to corrosion, combined with its unmatched longevity and durability, propel industrial processes to new heights. By reducing maintenance costs and enhancing operational efficiency, this groundbreaking component paves the way for increased productivity and profitability. With its adaptability to various industries and applications, the Ptfe Lined Alloy Cross offers a comprehensive and cost-effective solution for businesses seeking to optimize their operations. As the market continues to demand improved industrial efficiency, this innovative product proves to be a game-changer in the quest for sustainable and high-performance pipeline systems.

Discover the Advantages of Bonded PTFE Sheet for Various Applications

[Introduction]Innovations in the field of materials science are continuously shaping various industries, and the latest development in the realm of polytetrafluoroethylene (PTFE) technology is making waves. An emerging player in this space, {Company Name}, has recently introduced a groundbreaking product known as the Bonded PTFE Sheet, revolutionizing how industries utilize this versatile material. With its unique properties and diverse range of applications, this innovative sheet is poised to transform multiple sectors, from medical and automotive to aerospace and engineering.[Overview of PTFE and its significance]PTFE is a synthetic fluoropolymer of tetrafluoroethylene that possesses exceptional chemical resistance, low coefficient of friction, as well as excellent electrical insulation properties. These qualities have made PTFE a highly sought-after material across various industries. However, traditional PTFE sheets are known to have limitations due to their relatively weak bond strength when it comes to bonding with other substrates such as metals or plastics.[Bonded PTFE Sheet: A game-changer]Recognizing the need for a more reliable and versatile solution, {Company Name} developed the Bonded PTFE Sheet, engineered to address the bonding challenges associated with traditional PTFE sheets. By employing advanced adhesive technology, this innovative sheet combines the remarkable properties of PTFE with enhanced bond strength, offering unprecedented possibilities and applications.The Bonded PTFE Sheet features an enhanced surface treatment, allowing it to form strong bonds with various materials, including metals, plastics, rubbers, and composites. This breakthrough innovation expands the scope of applications for PTFE sheets, enabling engineers and designers to explore new avenues in their projects.[Applications in the medical industry]The medical industry is one such sector that stands to benefit significantly from the introduction of the Bonded PTFE Sheet. Its exceptional chemical resistance, biocompatibility, and low friction properties make it an ideal choice for medical devices, implants, and pharmaceutical applications. The enhanced bond strength further ensures the longevity and reliability of medical instruments while providing an additional layer of safety to patients.[Revolutionizing the automotive and aerospace sectors]In the automotive industry, the Bonded PTFE Sheet offers a multitude of advantages. Its low coefficient of friction aids in reducing wear and tear between moving components, thereby enhancing the overall efficiency and lifespan of the vehicles. Furthermore, its chemical resistance makes it an excellent choice for gaskets, seals, and electrical insulation, ensuring optimal performance in various automotive applications.Likewise, in the aerospace sector, the Bonded PTFE Sheet provides an innovative solution for critical applications. Its ability to withstand extreme temperatures, resist corrosion, and maintain mechanical integrity even in harsh environments is paramount in aerospace engineering. The increased bond strength ensures that vital components can withstand the rigors of space travel, making this sheet an invaluable addition to the industry.[Diversity in engineering applications]The engineering industry, encompassing a wide range of disciplines, can also harness the potential offered by the Bonded PTFE Sheet. Its unique combination of properties makes it an exceptional material choice for applications such as electrical insulation, sealing, and anti-corrosion protection. The enhanced bond strength expands the possibilities for engineers, allowing them to use PTFE in conjunction with other materials, thereby unlocking new realms of innovation.[Conclusion]With the introduction of the Bonded PTFE Sheet, {Company Name} has undoubtedly taken a significant step forward in improving the functionality and versatility of PTFE. This innovative product opens up a myriad of possibilities in various industries, enabling engineers and designers to push boundaries and explore new frontiers. As technology continues to advance, the importance of materials like the Bonded PTFE Sheet cannot be overstated, making it a game-changer that will undoubtedly shape the future of multiple sectors.

Heat-Resistant Plumbers Tape: A Comprehensive Guide

Plumbers Tape: The Ultimate Heat-Resistant Solution for All Your Plumbing NeedsPlumbing systems are an essential component of any building. From residential homes to commercial establishments, proper functioning plumbing is crucial for maintaining a clean and comfortable environment. However, plumbing systems are subject to wear and tear, which leads to common issues such as leaks and damaged pipes. To tackle these problems effectively, plumbers require the right tools and materials that can withstand the constant exposure to water, chemicals, and, most importantly, heat. This is where Plumbers Tape Heat Resistance comes to the rescue.Plumbers Tape is a versatile, high-quality tape that is specifically designed to provide excellent heat resistance properties. This innovative product ensures the durability and longevity of your plumbing systems, making it a must-have for plumbers and other professionals in the industry.With superior heat resistance capabilities, Plumbers Tape can endure extreme temperatures that commonly occur in plumbing systems. Whether it is the hot water running through pipes or the heat generated by nearby appliances, this tape will maintain its integrity and effectiveness. This means that users can rely on Plumbers Tape to prevent leaks, seal joints, and protect their plumbing systems from damage caused by excessive heat.One of the key features of Plumbers Tape is its compatibility with various plumbing materials. It can be used on pipes made of copper, PVC, and other commonly used materials. Regardless of the material, Plumbers Tape maintains a secure and tight seal, ensuring that leaks do not occur. This compatibility makes it an ideal solution for both residential and commercial plumbing projects.Furthermore, Plumbers Tape is easy to use, requiring no special skills or tools. It comes in a roll that can be easily cut to the desired length, allowing for customized applications. To apply the tape, simply wrap it around the pipe or joint, ensuring a proper seal. Its flexibility and adherence properties allow for seamless integration, providing a leak-proof solution.In addition to its heat resistance, Plumbers Tape also boasts excellent chemical resistance. It is impervious to a wide range of chemicals commonly found in plumbing systems, including acids, alkalis, solvents, and oils. This feature significantly enhances the tape's durability and reliability, making it suitable for even the most demanding plumbing applications.When it comes to choosing the right plumbing tape, Plumbers Tape stands apart from its competitors due to its superior quality and impressive reputation. Manufactured by {}, a renowned company with decades of experience in the plumbing industry, Plumbers Tape is trusted by professionals across the globe. {} is committed to delivering innovative and reliable solutions that meet the ever-evolving needs of its customers.As a market leader, {} continues to invest in research and development, ensuring that Plumbers Tape remains at the forefront of heat-resistant plumbing solutions. They adhere to strict quality control measures throughout the manufacturing process, guaranteeing a product that consistently meets and exceeds industry standards.In conclusion, Plumbers Tape Heat Resistance is the ultimate choice for maintaining and repairing plumbing systems. With its exceptional heat and chemical resistance properties, it provides a reliable and durable solution for professionals and DIY enthusiasts alike. Trust in the quality of {}'s products and invest in Plumbers Tape to ensure the longevity and efficiency of your plumbing systems.

Understanding the Significance and Features of Bridge Bearing Pads Made from Ptfe Material

Title: Advanced Bridge Bearing Pads Set to Revolutionize Infrastructure TechnologyIntroduction:In a bid to enhance the durability and safety of bridges, engineering materials and technology company XYZ introduces its latest innovation in bridge construction – the advanced Ptfe Bridge Bearing Pad. Engineered to withstand heavy loads, resist wear and tear, and provide superior stability, the company aims to revolutionize the infrastructure industry with this groundbreaking product.Understanding the Importance of Bridge Bearings:Bridge bearings play a critical role in facilitating movement and load distribution in bridge structures. These pads are typically placed between the superstructure and the substructure to minimize stress, accommodate thermal expansion, and allow for structural rotations and movements caused by external factors such as traffic, wind, and seismic events.Introducing Ptfe Bridge Bearing Pad:XYZ's Ptfe Bridge Bearing Pad is a result of extensive research and development aimed at creating a durable and reliable solution for bridge construction projects. These pads are made from high-strength polytetrafluoroethylene (PTFE) material, well-known for its excellent load-bearing capacity and low friction coefficient, making it perfect for use in bridge bearings.Key Features and Benefits:1. High Load-Bearing Capacity: The Ptfe Bridge Bearing Pad boasts exceptional load-bearing capacity, making it capable of withstanding heavy vehicular and structural loads. This ensures enhanced safety and longevity of bridge structures, reducing maintenance costs in the long run.2. Low Friction Coefficient: The low friction properties of the PTFE material reduce shear stress and resistance, resulting in smoother movement and minimizing energy dissipation. This feature greatly extends the service life of the bridge bearing system.3. Superior Durability: XYZ's bridge bearing pads are engineered to withstand harsh environmental conditions, including extreme temperatures, corrosive substances, and UV radiation. This durability reduces the need for frequent replacements and significantly cuts down maintenance expenses.4. Resistance to Wear and Tear: The PTFE material used in the bridge bearing pads exhibits exceptional resistance to wear and tear, ensuring long-term reliability. This feature makes them ideal for bridges with high traffic volumes or subjected to repetitive load cycles.5. Easy Installation and Maintenance: XYZ's bridge bearing pads are designed for easy installation, reducing construction time and costs. Furthermore, their low maintenance requirements contribute to the overall cost-effectiveness of bridge projects.Applications and Future Prospects:The Ptfe Bridge Bearing Pad by XYZ can be employed in a wide range of bridge construction projects, including highway bridges, railway bridges, pedestrian bridges, and even special structures like cable-stayed and suspension bridges. With its exceptional load-bearing capacity, durability, and low friction properties, this innovative solution is poised to revolutionize the infrastructure industry worldwide.Conclusion:XYZ's advanced Ptfe Bridge Bearing Pad has the potential to transform the construction landscape by providing engineers and builders with a groundbreaking solution that ensures safety, durability, and cost-effectiveness. With its superior load-bearing capacity, low friction properties, and resistance to wear and tear, bridge structures incorporating these pads will boast enhanced longevity and require minimal maintenance. XYZ's commitment to engineering excellence positions them at the forefront of infrastructure technology, promising a more secure and efficient future for the world's bridges.

High-Quality Plumbers Tape: A Must-Have for Every Toolbox

Wide Plumbers Tape Launches Innovative New Product LineWide Plumbers Tape, a leading provider of plumbing supplies, has announced the launch of its innovative new product line, designed to streamline and improve plumbing repair and installation.The company, which has been in operation for over 20 years, is known for its high-quality plumbing tape and other sealing products. With the introduction of their new product line, Wide Plumbers Tape seeks to further solidify its position as a go-to source for plumbing professionals and DIY enthusiasts alike.One of the highlights of the new product line is the introduction of a wide variety of tape widths, ranging from 2 inches to 6 inches. This wide range of widths allows plumbers and homeowners to select the best size of tape for their specific project, ensuring a more secure and reliable seal.In addition to the various widths, the new line also includes specialized tapes for different applications, such as high-temperature tapes for hot water and steam applications, as well as tape with extra gripping power for extra security in high-pressure situations.Wide Plumbers Tape has a long-standing reputation for reliability and innovation. Their products are known for their durability and ease of use, making them a top choice for professionals and beginners alike.A spokesperson for Wide Plumbers Tape noted, "We are proud to continue our tradition of excellence with the introduction of our new product line. These new tapes have been developed with the input of professionals in the field, ensuring that they meet the needs of plumbers and homeowners alike."The company has also introduced a new and improved dispensing system for their tape products, which allows for easier and more efficient application. This new system is designed to reduce waste and save time on the job, further enhancing the overall user experience.Wide Plumbers Tape has built a strong reputation for providing high-quality products at competitive prices. They are dedicated to ensuring that their customers have access to the best materials for their plumbing needs, and the introduction of this new line is a testament to that commitment.The new product line from Wide Plumbers Tape is now available for purchase online and in select retail locations. The company has also announced that they will be offering special promotions and discounts to celebrate the launch of the new line, making it an ideal time for plumbing professionals and DIY enthusiasts to stock up on these innovative new products.With the introduction of their new product line, Wide Plumbers Tape demonstrates their ongoing dedication to innovation and excellence in the field of plumbing supplies. As the company continues to expand and evolve, they remain a trusted source for premium-quality plumbing products.In summary, Wide Plumbers Tape has launched a new product line that includes a variety of tape widths and specialized tapes for different applications. The introduction of this innovative new line further solidifies the company's position as a leading provider in the field of plumbing supplies. With a strong reputation for reliability and innovation, Wide Plumbers Tape continues to be a top choice for professionals and DIY enthusiasts seeking high-quality plumbing materials.

Bridge Applications: Unveiling the Versatility and Utility of Neoprene

Title: Cutting-Edge Material Revolutionizes Bridge Design and ConstructionIntroduction:Bridges, an indispensable infrastructural component, have historically been designed using conventional materials such as steel and concrete. However, in a groundbreaking development, engineers at a prominent construction company have unveiled a cutting-edge material, referred to as NP1, which promises to revolutionize bridge design and construction. Developed to enhance structural integrity while ensuring long-lasting durability, NP1 represents a major innovation in the field of civil engineering. Let's delve into the remarkable properties of this state-of-the-art material and the impacts it may have on future bridge designs.1. The Advent of NP1 Material:NP1, a breakthrough material, is a proprietary blend of advanced polymers, synthetic fibers, and special additives. This innovative composition provides superior mechanical strength, excellent resistance to corrosion, and remarkable flexibility. The engineers behind NP1 envision a future where traditional steel and concrete bridges will give way to lighter, more sustainable structures, capable of withstanding harsh environmental conditions.2. Key Features and Advantages of NP1:The unique properties of NP1 have garnered attention and favor from industry experts worldwide. Some of the key features and advantages are:a. Unparalleled Durability: NP1 exhibits exceptional resistance to external factors such as saltwater, extreme temperatures, and corrosive substances. This longevity significantly reduces maintenance costs associated with bridge structures, making NP1 an economically viable alternative.b. Enhanced Structural Integrity: Thanks to its superior mechanical strength, NP1 bridges can support heavier loads over longer spans. This advantage not only ensures safer transportation but also expands the possibilities for architectural expression and bridge design innovation.c. Cost-Efficiency: While the initial investment in NP1 might be higher than traditional materials, the extended service life and reduced maintenance requirements result in substantial cost savings in the long run. Additionally, the lightweight nature of NP1 facilitates easier and quicker construction, further reducing labor costs.d. Eco-Friendly Construction: NP1 bridges require fewer raw materials and resources compared to conventional designs. Reduced reliance on steel and concrete contributes to a decrease in carbon emissions during the manufacturing process. Furthermore, NP1 is 100% recyclable, making it an environmentally responsible choice for sustainable infrastructure development.3. Successful Implementation of NP1:Several high-profile bridge projects have already incorporated NP1, serving as a testament to its effectiveness and reliability. One noteworthy example is the recently completed XYZ Bridge, a colossal structure connecting two major cities. This bridge's innovative design maximizes NP1's flexibility while maintaining its load-bearing capacity, ensuring the safety and convenience of commuters.4. Future Prospects and Potentials:The introduction of NP1 opens up exciting possibilities for bridge design and construction. With ongoing research and development, this cutting-edge material can be further refined to be even stronger and more versatile. NP1 has also sparked interest in designing environmentally friendly bridges, promoting sustainable infrastructure in line with global climate goals.5. Regulatory Considerations and Guidelines:Due to the novelty of NP1, regulatory bodies and construction standards agencies must update guidelines to include the specifications and requirements for implementing this material in bridge projects. Collaborations between engineers, researchers, and government agencies will be crucial to ensure safe, reliable, and standardized usage of NP1 in future bridge constructions.Conclusion:As the construction industry embraces advanced materials and technology, NP1 emerges as a game-changer in bridge design and construction. Its unmatched durability, superior mechanical properties, and eco-friendly characteristics make NP1 a viable alternative to traditional materials. With a track record of successful implementation and ongoing research efforts, NP1 has the potential to redefine bridge construction standards while driving sustainable infrastructure development for future generations.

A Guide to Amber Glass Reagent Bottles - Why They're Essential for Laboratory Use

Title: Ambershield Introduces Revolutionary Reagent Bottle for Enhanced Chemical Storage SafetyIntroduction:Ambershield, a global leader in laboratory equipment manufacturing, is excited to announce the launch of their innovative Reagent Bottle Amber Glass. Designed with utmost precision and incorporating the latest technological advancements, this groundbreaking product ensures improved chemical storage safety in laboratories, pharmaceutical research facilities, and industrial settings. Ambershield's focus on quality and customer satisfaction remains at the forefront, offering highly reliable and durable laboratory solutions that surpass industry standards.Enhancing Safety in Chemical Storage:When working with hazardous chemicals, proper handling and storage are of paramount importance to safeguard the well-being of scientists and minimize the risk of accidents. Traditional reagent bottles made from clear glass or plastic often fail to provide adequate protection against exposure to harmful UV light and harsh chemicals. Recognizing this crucial need, Ambershield has developed its Reagent Bottle Amber Glass, carefully engineered to safeguard the integrity of sensitive reagents and optimize safety precautions.Unparalleled Protection:The key feature of the Reagent Bottle Amber Glass is its superior light-filtering properties. The amber-colored glass effectively blocks harmful UV radiation, preventing degradation of light-sensitive substances stored within. This breakthrough technology ensures that delicate reagents and solutions remain stable and their integrity is preserved, reducing the risk of contamination and potential compromise in experimental outcomes.Furthermore, the high-quality borosilicate glass used in the manufacture of these bottles provides exceptional resistance to corrosion from a wide range of chemicals. The robust construction, coupled with Ambershield's stringent quality control processes, guarantees long-term durability, limiting the possibility of leaks or breakages that could jeopardize the safety of both personnel and the laboratory environment.Improved User Experience:Ambershield gives utmost priority to user convenience and ergonomics. The Reagent Bottle Amber Glass is intelligently designed with a wide mouth, facilitating effortless pouring and ensuring precise measurement of reagents. The bottle's airtight screw cap prevents accidental leaks and evaporation, maintaining the integrity of the stored chemicals, even in demanding laboratory environments.Easy Identification and Compliance:Ambershield understands the importance of efficient lab management and keeping in line with regulatory guidelines. The brand ensures all their Reagent Bottle Amber Glass products are clearly marked with calibrated volume indicators, facilitating accurate measurement and dosage. Additionally, each bottle is imprinted with chemical-resistant labels, ensuring proper identification, traceability, and compliance with safety regulations.Sustainable and Environmentally-Friendly Solutions:Ambershield is committed to environmental sustainability, and the Reagent Bottle Amber Glass is no exception. Made from high-quality recyclable borosilicate glass, these bottles can be reused numerous times without compromising their structural integrity. By investing in these eco-friendly reagent bottles, laboratories and pharmaceutical research facilities contribute to minimizing single-use plastic waste and promote a greener, more sustainable future.Availability and Future Prospects:Ambershield's Reagent Bottle Amber Glass is now available for purchase through their trusted global network of distributors. With a comprehensive range of sizes and capacities, Ambershield caters to the diverse storage needs of laboratories worldwide. Furthermore, Ambershield's commitment to continuous improvement ensures constant research and development, guaranteeing the introduction of advanced lab equipment solutions that meet the evolving requirements of scientific advancements.Conclusion:Ambershield's Reagent Bottle Amber Glass represents a significant breakthrough in enhancing chemical storage safety. By combining cutting-edge technology, rigorous quality standards, and a commitment to customer satisfaction, Ambershield once again reaffirms its position as a global leader in laboratory equipment manufacturing. The advanced protective properties, user-friendly design, and eco-friendly nature make the Reagent Bottle Amber Glass the ultimate choice for laboratories seeking enhanced safety and optimal preservation of sensitive reagents.

Dip Pipe Market Witnessing High Demand and Growth Opportunities

[Company Name] Introduces Innovative PTFE Dip Pipe Solution for Industrial Applications[City, Date] – [Company Name], a leading provider of advanced industrial solutions, is pleased to announce the launch of their state-of-the-art PTFE Dip Pipe. Designed for optimal performance and enhanced durability, this revolutionary product is set to significantly improve various industrial applications.To address the growing demand for reliable and efficient piping solutions, [Company Name] has developed the PTFE Dip Pipe, a game-changer in the industry. With its exceptional resistance to chemicals, pressure, and extreme temperatures, this innovative product is poised to revolutionize industrial processes.The PTFE Dip Pipe is crafted from Polytetrafluoroethylene (PTFE), a synthetic fluoropolymer of tetrafluoroethylene. PTFE is known for its excellent chemical resistance and nonstick properties, making it a preferred material for a wide range of applications. The use of PTFE ensures that the dip pipe can withstand aggressive substances found in industrial processes, including corrosive chemicals, acids, and bases.One of the notable features of the PTFE Dip Pipe is its exceptional temperature resistance. With a melting point of approximately 327 degrees Celsius (621 degrees Fahrenheit), the dip pipe can operate reliably in extreme conditions without any degradation. This makes it an ideal choice for industries dealing with abrasive or high-temperature environments, such as chemical processing, petrochemical, and pharmaceutical industries.Furthermore, the PTFE Dip Pipe offers excellent mechanical properties, including high tensile strength and low friction coefficient. These features contribute to its outstanding durability and longevity, ensuring a longer service life compared to conventional piping materials. The dip pipe also exhibits high stability, even under continuous exposure to harsh operating conditions, eliminating the need for frequent maintenance and replacements.The unique design of the PTFE Dip Pipe provides exceptional flexibility for various configurations and applications. Its versatility allows it to be integrated seamlessly into existing industrial systems, delivering unmatched performance and reliability. Whether used for transporting aggressive chemicals, corrosive gases, or abrasive slurries, the dip pipe offers a superior solution for reliable and efficient fluid management."By introducing our PTFE Dip Pipe, we aim to meet the evolving needs of the industrial sector," said [Name], [Position] at [Company Name]. "Our team has worked diligently to develop this groundbreaking product, which upholds our commitment to delivering high-quality solutions that enhance productivity and safety in industrial processes."[Company Name] is renowned for its dedication to research and development, consistently striving to provide innovative solutions that cater to the ever-changing demands of the industrial market. With the introduction of the PTFE Dip Pipe, the company further solidifies its position as an industry leader, setting new standards in fluid management.As demand for efficient and durable piping solutions continues to rise, [Company Name] aims to fulfill the market's needs with its advanced PTFE Dip Pipe. By leveraging expertise, cutting-edge technology, and a commitment to customer satisfaction, the company is poised to revolutionize the industrial sector and enhance operational excellence for its valued clients.About [Company Name]:[Company Name] is a leading provider of advanced industrial solutions, specializing in the development and manufacturing of innovative products. With a strong emphasis on research and development, the company strives to deliver cutting-edge solutions that enhance productivity, safety, and sustainability. Backed by a team of highly skilled professionals, [Company Name] is committed to exceeding customer expectations and creating long-lasting partnerships.For media inquiries, please contact:[Contact Name][Position][Company Name][Email][Phone Number]

Non-Stick Coating for Pipes: A Game-Changer in Plumbing Technology

The {Company} is pleased to announce the release of a new innovative product that is set to revolutionize the piping industry. The company has recently launched a new line of Teflon-coated pipes that are designed to provide superior performance and durability compared to traditional piping materials. With this new product, {Company} aims to offer long-term solutions for various industries such as chemical processing, oil and gas, food and beverage, and many others.The new Teflon-coated pipes are specifically engineered to withstand harsh environments and corrosive substances, making them an ideal choice for industries that require reliable and long-lasting piping systems. The Teflon coating not only provides excellent resistance to chemical reactions, but it also offers a smooth surface that minimizes friction and allows for efficient flow of liquids through the pipes. This unique combination of properties makes Teflon-coated pipes the ideal choice for industries that demand high performance and reliability from their piping systems.In addition to the outstanding performance of the Teflon-coated pipes, {Company} takes pride in its commitment to sustainability and environmental responsibility. The Teflon coating used in the pipes is designed to be environmentally friendly and non-toxic, ensuring that the company's products are in line with the latest environmental regulations and standards. This focus on sustainability sets {Company} apart from its competitors and reinforces its dedication to offering innovative solutions that not only meet industry demands but also contribute to a more sustainable future.{Company} has a long-standing reputation for delivering high-quality products and exceptional customer service. With a track record of successful projects and satisfied clients, the company has established itself as a trusted partner for industries that demand the highest standards in performance and reliability. The launch of the new Teflon-coated pipes further strengthens {Company}'s position in the market and demonstrates its continued commitment to innovation and excellence."We are thrilled to introduce our new Teflon-coated pipes to the market," said {Spokesperson} of {Company}. "These pipes represent a significant advancement in piping technology, and we are confident that they will set a new standard for performance and reliability in the industry. With our expertise and dedication to excellence, {Company} is poised to become a leading provider of Teflon-coated pipes for a wide range of industrial applications."The launch of the Teflon-coated pipes is just one example of {Company}'s ongoing efforts to push the boundaries of innovation and bring new, sustainable solutions to the market. With a team of experienced engineers and industry experts, the company is well-positioned to continue developing cutting-edge products that address the evolving needs of various industries. By focusing on quality, performance, and sustainability, {Company} remains committed to delivering value to its clients and driving positive change in the industry.As {Company} introduces its new Teflon-coated pipes to the market, it is clear that the company is shaping the future of the piping industry with its innovative solutions and unwavering commitment to excellence. With a focus on performance, reliability, and sustainability, {Company} is well poised to lead the way in providing advanced piping solutions for a wide range of industries. The launch of the Teflon-coated pipes is a significant milestone for the company and reaffirms its position as a trusted partner for industries that demand the best.