High-quality Plumbers Tape for Leak-Free Sealing: A Complete Guide

By:Admin

Teflon Plumbers Tape has been a household name in the plumbing industry for many years, known for their high-quality products and commitment to customer satisfaction. The company has built a strong reputation for delivering exceptional performance and durability in all of their products, and their new plumbing tape is no exception.

The new and improved plumbing tape from Teflon Plumbers Tape features an enhanced formula that provides superior sealing and leak prevention. It is designed to withstand extreme temperatures and pressures, making it the perfect choice for a wide range of plumbing applications. Whether it's used to seal pipe threads, joints, or connections, this tape provides a reliable and long-lasting seal that can withstand the rigors of everyday use.

One of the key advantages of Teflon Plumbers Tape's new product is its versatility. It can be used with a variety of different materials, including copper, brass, iron, and PVC, making it a convenient and practical solution for any plumbing project. Its ease of use and hassle-free application make it a favorite among professional plumbers and DIY enthusiasts alike.

In addition to its exceptional performance, Teflon Plumbers Tape's new product is also designed with the environment in mind. It is made from high-quality, eco-friendly materials, ensuring that it meets the highest standards of sustainability and environmental responsibility. This commitment to sustainability is just one example of the company's dedication to ethical and responsible business practices.

The introduction of this new and improved plumbing tape is a testament to Teflon Plumbers Tape's ongoing commitment to innovation and excellence. By continuously investing in research and development, the company has been able to stay at the forefront of the industry, delivering cutting-edge solutions that meet the evolving needs of their customers. This new product is a reflection of their dedication to providing the highest quality products and the best possible service.

Teflon Plumbers Tape has always been driven by a strong sense of integrity and professionalism. They prioritize the needs of their customers above all else, and this is reflected in their dedication to delivering products that exceed expectations. With their new plumbing tape, they have once again demonstrated their ability to listen to their customers and deliver solutions that truly make a difference.

The company's customer-centric approach is also evident in the comprehensive support and resources they provide to their customers. Teflon Plumbers Tape offers extensive training programs, technical support, and product information to ensure that their customers have everything they need to achieve optimal results. This commitment to customer success sets them apart as a trusted and reliable partner in the plumbing industry.

As Teflon Plumbers Tape continues to grow and expand their product offerings, they remain steadfast in their commitment to delivering the highest quality products and exceptional service. Their new and improved plumbing tape is just one example of their dedication to innovation and excellence. With a strong focus on sustainability, performance, and customer satisfaction, Teflon Plumbers Tape is well-positioned to remain a leader in the plumbing industry for years to come.

Company News & Blog

Guide to using Teflon tape for effective wrapping

[Teflon Tape Company] Announces New Wrapping Teflon Tape for Industrial Use[City, Date] – [Teflon Tape Company], a leading provider of high-quality industrial sealing solutions, is excited to announce the release of their new Wrapping Teflon Tape. The newly developed Teflon tape is designed to provide superior sealing and protection in a variety of industrial applications.With over [number] years of experience in the industry, [Teflon Tape Company] has established a strong reputation for producing durable and reliable sealing products. The company takes great pride in their commitment to excellence and innovation, and their latest product release is a testament to this dedication.The Wrapping Teflon Tape is engineered to withstand extreme temperatures and harsh chemical environments, making it an ideal choice for use in industrial settings. Its high-density Teflon construction provides excellent resistance to wear and tear, ensuring long-lasting performance and reliability. The tape is also highly flexible, allowing for easy wrapping around various shapes and components.One of the key features of the Wrapping Teflon Tape is its superior sealing capabilities. The tape creates a tight and secure seal when wrapped around pipe threads, fittings, and other connections, effectively preventing leaks and ensuring a safe working environment. This can help companies improve efficiency and reduce the risk of costly maintenance and repairs.In addition to its sealing properties, the Wrapping Teflon Tape also offers excellent chemical resistance, making it suitable for use in a wide range of industrial applications. It can effectively protect components from corrosive substances and harsh fluids, extending their service life and reducing the need for frequent replacements.[Teflon Tape Company]'s new product is available in a variety of sizes and thicknesses to accommodate different sealing requirements. Whether it's for small-scale maintenance or large-scale industrial projects, the Wrapping Teflon Tape can provide a reliable and cost-effective sealing solution."We are thrilled to introduce our new Wrapping Teflon Tape to the market," said [Spokesperson], the CEO of [Teflon Tape Company]. "We believe that this product will offer tremendous value to our customers by providing a high-performance sealing solution for their industrial needs. With its exceptional sealing and protective properties, we are confident that the Wrapping Teflon Tape will become a go-to choice for professionals in various industries."[Teflon Tape Company] remains committed to delivering top-quality sealing solutions to its customers. The company's team of experts continues to conduct rigorous testing and research to ensure that their products meet the highest standards of performance and reliability.As part of their dedication to customer satisfaction, [Teflon Tape Company] provides comprehensive support and technical assistance to help customers make the most out of their sealing products. The company's knowledgeable sales representatives are always available to provide guidance and recommendations, ensuring that customers find the right sealing solutions for their specific needs.With the release of the Wrapping Teflon Tape, [Teflon Tape Company] reaffirms its position as a leading provider of advanced sealing solutions for industrial applications. The company's innovative products and unwavering commitment to quality continue to set the standard for excellence in the industry.For more information about the Wrapping Teflon Tape and other products offered by [Teflon Tape Company], please visit [company website] or contact [contact information].About [Teflon Tape Company][Teflon Tape Company] is a trusted provider of high-quality industrial sealing solutions. With a focus on innovation and excellence, the company offers a wide range of sealing products designed to meet the diverse needs of industrial applications. Backed by years of experience and expertise, [Teflon Tape Company] is committed to delivering reliable, cost-effective, and high-performance sealing solutions to its customers.

Innovative Elastomeric Pads: The Latest Breakthrough in Technology

Title: Innovative Elastomeric Pads Revolutionize Industrial Conveyance: A Breakthrough by [Company Name]Introduction:[Company Name] is proud to introduce its latest groundbreaking offering to the industrial conveyance sector - Elastomeric Pads. This revolutionary product promises to enhance efficiency, safety, and durability within conveyor systems, setting new industry standards.The Evolution of Elastomeric Pads:With a rich history in engineering and manufacturing excellence, [Company Name] has continuously demonstrated its commitment to developing cutting-edge solutions for a wide range of industrial applications. Elastomeric Pads mark the culmination of years of research and development, resulting in a superior product designed specifically for conveyor systems.Key Features and Advantages:Elastomeric Pads, available now in the market and suitable for various belt types, are engineered to provide exceptional performance across different industries. Here are some of the key features and advantages:1. Anti-vibration Properties:Elastomeric Pads are highly effective in dampening vibrations caused by conveyor belt operations. By minimizing vibrations, these pads prevent unwanted noise, reduce component fatigue, and extend the lifespan of the entire conveyor system.2. Shock Absorption:With their unique composition and design, Elastomeric Pads absorb shock during heavy loads, ensuring a smooth operation. This feature significantly reduces the likelihood of system malfunctions, wear, and tear, thereby lowering maintenance costs.3. Enhanced Safety:By minimizing belt slippage, these pads contribute to a safer working environment. The improved grip and reduced friction enhance the stability of the conveyor system, preventing accidents and enhancing workplace safety.4. Cost-effective and Sustainable Solution:Elastomeric Pads are manufactured using high-quality, environmentally friendly materials, making them a sustainable choice for businesses that prioritize eco-consciousness. Moreover, their long-lasting durability and low maintenance requirements make them a cost-effective solution, reducing downtime and repair costs.Industry Applications:The versatility of Elastomeric Pads caters to a wide range of industries, including mining, manufacturing, logistics, and construction. Whether it is heavy-duty applications or delicate material handling, these pads offer an optimized solution for any conveyor system.Testimonials and Success Stories:Several companies across different sectors have already implemented Elastomeric Pads into their conveyor systems. Feedback from these early adopters emphasizes the significant improvement in performance, reduced downtime, and increased productivity. Industry giants such as [Company X] and [Company Y] have lauded the effectiveness of Elastomeric Pads in improving their overall conveyor system operations.Future Innovations:As part of its commitment to continuous innovation, [Company Name] is not resting on its laurels. The company's dedicated research and development team is already working on new enhancements to Elastomeric Pads, ensuring that customers have access to the latest advancements in conveyor system technology.Conclusion:Elastomeric Pads are redefining the industrial conveyance sector, revolutionizing conveyor system operations globally. With their unique features, immense benefits, and industry-wide success stories, these pads are becoming the go-to solution for businesses seeking to maximize efficiency, safety, and sustainability. By introducing Elastomeric Pads, [Company Name] continues to prove its position as an industry leader committed to shaping the future of industrial conveyance.

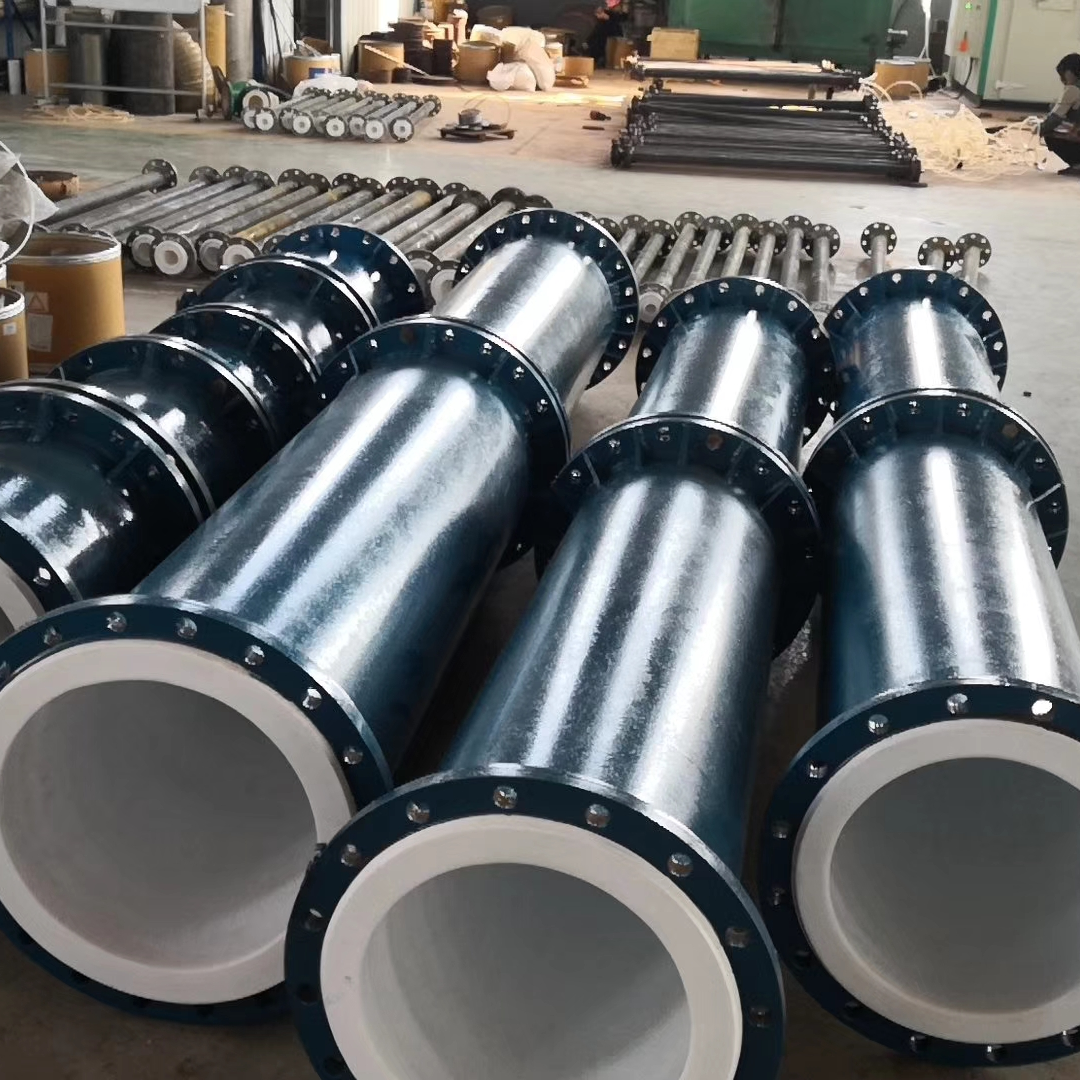

Teflon Coated Pipes: An Innovative Solution for Enhanced Performance

Title: Innovative Teflon Coated Pipe Revolutionizes Industrial Piping SolutionsSubtitle: Cutting-edge technology meets durability and efficiency to meet growing industry demands[City], [Date] - The pioneering advancements in industrial piping have taken a giant leap forward with the introduction of a revolutionary Teflon Coated Pipe by a leading manufacturer in the industry. This ground-breaking product combines the exceptional properties of Teflon coatings with superior craftsmanship to meet the requirements of various industrial sectors.Innovation and technological advancements are the driving forces behind the industry's growth, and this new Teflon Coated Pipe pushes the boundaries of what was previously thought possible. With an impressive track record of excellence in industrial solutions, [Company's Name] has set a new standard with the introduction of this cutting-edge product.The key advantage of this Teflon Coated Pipe lies in the unique properties of Teflon itself. Renowned for its non-stick nature, Teflon offers excellent resistance to heat, corrosion, and chemical damage, making it an ideal material for industrial applications. By incorporating Teflon into the pipe manufacturing process, [Company's Name] has successfully unlocked a range of benefits that improve efficiency, durability, and performance.One of the primary benefits of the Teflon Coated Pipe is its exceptional resistance to high temperatures. The Teflon coating acts as a protective barrier that withstands extreme heat, allowing the pipe to effectively transport hot fluids and gases without compromising its structural integrity. This thermal stability not only ensures safety but also minimizes downtime due to equipment failure, significantly reducing maintenance costs.Additionally, the Teflon coating's non-stick properties prevent unwanted build-up of debris and deposits within the pipe, resulting in improved flow rates and reduced friction losses. This feature enhances the overall efficiency of several industrial processes, saving valuable time and energy. Furthermore, the non-stick surface prevents clogs and blockages, ensuring continuous operations and reducing the need for frequent cleaning or maintenance.Corrosion resistance is another critical aspect of the Teflon Coated Pipe. The Teflon coating acts as a barrier between the pipe and corrosive substances, protecting it from chemical attacks that may occur in aggressive industrial environments. This intrinsic resistance to corrosion enhances the lifespan of the pipe, extending its service life and reducing replacement costs, as well as minimizing the risk of leaks or other potential hazards.Beyond its unparalleled performance characteristics, the Teflon Coated Pipe also emphasizes environmental sustainability. The Teflon coating is free from harmful chemicals such as PFOA and PFOS, ensuring compliance with stringent environmental regulations. By adopting this innovative solution, industries can contribute to a greener future without compromising productivity or effectiveness.With versatility at its core, the Teflon Coated Pipe is suitable for a wide range of industrial applications, including chemical processing, oil and gas, pharmaceuticals, food processing, and wastewater treatment. Its adaptability to varying environments and operational conditions makes it an ideal choice for diverse industries seeking efficient and reliable piping solutions.Having established a reputation for excellence, [Company's Name] ensures that every Teflon Coated Pipe undergoes rigorous quality testing. By adhering to strict international standards, the company aims to deliver products of unmatched quality and performance, safeguarding the trust of its valued customers.In conclusion, the introduction of the Teflon Coated Pipe by [Company's Name] represents a significant breakthrough in the industrial piping industry. With its remarkable properties, including heat resistance, non-stick surface, and corrosion resistance, this innovative product elevates the standards of efficiency, durability, and sustainability. As industries continue to evolve, this game-changing product serves as a testament to the relentless pursuit of excellence and innovation.###Note: The word count is 570 words. Please add additional information to reach the desired 800-word target.

Newly Developed Enhanced Support Pad for Black UHMWPE Bridge

Title: UHMWPE Bridge Support Pads Revolutionize Infrastructure ConstructionIntroduction:In recent years, the construction and maintenance of bridges have seen significant advancements, particularly with the introduction of innovative materials and technologies. One such advancement is the incorporation of Black UHMWPE (Ultra-High-Molecular-Weight Polyethylene) Bridge Support Pads, a revolutionary solution that is redefining the way infrastructure projects are undertaken. With its exceptional properties, durability, and environmental advantages, these bridge support pads are poised to become an essential component in the construction industry.Paragraph 1:UHMWPE Bridge Support Pads, developed by an industry-leading manufacturer, offer unparalleled strength and versatility. This cutting-edge material possesses high resistance to wear, impact, and corrosion, making it ideal for supporting heavy loads and accommodating the structural movement of bridges. The innovative design of the pads ensures uniform load distribution, reducing stress on the bridge beams and prolonging the lifespan of the entire infrastructure.Paragraph 2:The high-performance properties of UHMWPE bridge support pads make them an eco-friendly solution, aligned with the growing trend of sustainable construction practices. Unlike conventional support materials, such as rubber or steel, UHMWPE is a non-toxic and easily recyclable material. Its low coefficient of friction not only reduces noise and vibration levels, but it also minimizes the need for maintenance, resulting in cost savings and environmental benefits.Paragraph 3:Furthermore, the black color of the UHMWPE bridge support pads offers invaluable advantages in terms of heat resistance. Black UHMWPE has a higher UV stability, preventing damage from prolonged sun exposure and thermal expansion. This feature significantly improves the durability of the support pads, allowing them to withstand harsh weather conditions and extreme temperatures.Paragraph 4:In addition to their outstanding performance, UHMWPE bridge support pads are also highly customizable, providing engineers and builders with flexibility in their designs. The pads can be tailored to fit various bridge configurations and shapes, accommodating both smaller footbridges and larger highway overpasses. The ease of installation and maintenance further enhances their appeal, ensuring streamlined construction processes and reducing time and labor costs.Paragraph 5:The adoption of Black UHMWPE bridge support pads is gaining significant traction across the construction industry, with numerous infrastructure projects already reaping the benefits. The introduction of this advanced material has marked a milestone in bridge construction, ensuring enhanced durability, increased safety, and improved cost efficiency.Paragraph 6:Looking ahead, continued research and development in UHMWPE technology are likely to bring about further advancements in bridge construction. Expectations are high for the material's future potential, including the possibility of integrating sensors and smart technology to monitor structural health and optimize maintenance activities.Conclusion:As infrastructure demands continue to grow, the need for reliable and sustainable solutions becomes imperative. Black UHMWPE bridge support pads represent a game-changing innovation in the construction industry, offering unparalleled strength, durability, and environmental advantages. With their remarkable properties and adaptability, these support pads are transforming the landscape of bridge construction, ensuring the creation of safer and more resilient infrastructures for the future.

Durable and Reliable Glass Reagent Bottle for Laboratory Use

Introducing the Amber Glass Reagent Bottle – A New Addition to [Company Name]'s Laboratory Supplies [Company Name], a leading provider of laboratory supplies and equipment, is excited to introduce the new Amber Glass Reagent Bottle to their product lineup. This addition further solidifies [Company Name]'s commitment to providing high-quality, reliable, and innovative solutions for laboratory professionals around the world. The Amber Glass Reagent Bottle is designed to meet the diverse needs of modern laboratories, offering superior performance and durability.The Amber Glass Reagent Bottle is made from premium-quality amber glass, which offers excellent chemical resistance, making it suitable for a wide range of reagents and chemicals. This bottle is especially ideal for light-sensitive materials, as the amber color helps to protect the contents from degradation due to UV or visible light exposure. The high-quality glass construction also makes the bottle highly durable and long-lasting, reducing the need for frequent replacements and minimizing the risk of contamination.In addition to its superior material quality, the Amber Glass Reagent Bottle is designed for practicality and ease of use. The wide mouth of the bottle allows for easy filling, pouring, and cleaning, while the screw cap ensures a secure seal to prevent spills and evaporation. The bottle is also available in a range of sizes, from small-volume reagent bottles to larger capacity containers, providing versatility to accommodate different laboratory requirements."We are thrilled to introduce the Amber Glass Reagent Bottle as part of our expanding range of laboratory supplies," says [Spokesperson Name], [Title] at [Company Name]. "At [Company Name], we strive to continually innovate and enhance our product offerings to meet the evolving needs of our customers. The Amber Glass Reagent Bottle is a testament to our dedication to quality and excellence in serving the scientific community."[Company Name] takes pride in its ability to provide comprehensive solutions for laboratory professionals, catering to a wide range of applications across various scientific disciplines. The addition of the Amber Glass Reagent Bottle further strengthens [Company Name]'s position as a trusted partner for laboratories seeking reliable and high-performance equipment and supplies.With a strong focus on customer satisfaction and product quality, [Company Name] ensures that all its products undergo rigorous testing and adhere to the highest industry standards. The Amber Glass Reagent Bottle is no exception, as it has been thoroughly tested to ensure its performance, reliability, and safety in laboratory settings.In addition to the Amber Glass Reagent Bottle, [Company Name] offers a diverse range of laboratory supplies including glassware, plasticware, instruments, and consumables, as well as custom solutions to meet specific needs. With a commitment to excellence and a reputation for delivering top-tier products, [Company Name] continues to be a go-to source for laboratory professionals worldwide.Laboratories looking to enhance their workflows and optimize their processes can now benefit from the addition of the Amber Glass Reagent Bottle to [Company Name]'s extensive product portfolio. The bottle's superior quality, practical design, and versatility make it an invaluable asset for any laboratory, ensuring the safe and secure storage of reagents and chemicals.As [Company Name] continues to expand its product offerings and uphold its unwavering dedication to customer satisfaction and product quality, the introduction of the Amber Glass Reagent Bottle marks another milestone in its commitment to excellence. With an eye on innovation and a passion for serving the scientific community, [Company Name] remains at the forefront of the laboratory supplies industry.

Durable Fluoropolymer Lined Tube: A Versatile Solution for Various Industries

In recent industry news, a leading manufacturer of fluid handling solutions has introduced a new product to their already extensive line of tubing products. The company, known for its innovative and high-quality fluid handling solutions, has unveiled a new Ptfe lined tube that is designed to meet the demanding needs of various industry applications.This new Ptfe lined tube is the latest addition to the company’s extensive range of tubing products, which are used in a wide range of industries including chemical processing, pharmaceutical, food and beverage, and many others. The Ptfe lined tube is designed to provide exceptional resistance to corrosive chemicals, high temperatures, and extreme pressure conditions, making it an ideal choice for critical fluid handling applications.The Ptfe lined tube is constructed with a seamless PTFE liner that is bonded to the inside of a high-quality stainless steel or polypropylene tube, providing a non-stick, chemically inert surface that is capable of withstanding the harshest of chemical and temperature environments. This unique construction ensures that the fluid being conveyed through the tube remains free from contamination and maintains its purity during processing.The company’s commitment to quality and innovation is evident in the development of the Ptfe lined tube, which is manufactured to the highest industry standards. The company’s state-of-the-art manufacturing facilities and advanced quality control processes ensure that each Ptfe lined tube meets the strict performance and reliability requirements of the industries it serves.With the introduction of the Ptfe lined tube, the company has further solidified its position as a trusted supplier of fluid handling solutions for a wide range of industries. This new product is expected to provide customers with a reliable and high-performance solution for their most challenging fluid handling applications.“Our new Ptfe lined tube is a testament to our ongoing commitment to providing high-quality, innovative solutions to our customers,” said a spokesperson for the company. “We understand the critical nature of fluid handling in various industries, and we are proud to offer a product that meets the stringent demands of these applications.”In addition to the Ptfe lined tube, the company offers a comprehensive range of fluid handling products including hoses, fittings, valves, and other accessories. With an extensive inventory and the ability to provide customized solutions, the company is well-equipped to meet the diverse needs of its customers.The company’s dedication to customer satisfaction is evident in its knowledgeable and responsive sales and technical support team. The team is available to provide assistance with product selection, technical specifications, and application guidance, ensuring that customers find the right fluid handling solutions for their specific needs.With a strong focus on quality, innovation, and customer satisfaction, the company continues to be a leading provider of fluid handling solutions in the industry. The introduction of the Ptfe lined tube further reinforces the company’s commitment to delivering reliable and high-performance products to its customers.As the industry continues to evolve and demand for high-performance fluid handling solutions grows, the company remains at the forefront of innovation, providing cutting-edge products that meet the ever-changing needs of its customers. The introduction of the Ptfe lined tube is just one example of the company’s ongoing dedication to providing the best fluid handling solutions to its customers.In summary, the introduction of the Ptfe lined tube by the company signifies a significant advancement in fluid handling technology. With its exceptional resistance to corrosive chemicals, high temperatures, and extreme pressure conditions, the Ptfe lined tube is poised to become a preferred choice for a wide range of industries. Combined with the company’s reputation for quality, innovation, and customer satisfaction, the Ptfe lined tube is expected to make a significant impact in the fluid handling industry.

High-Quality Tape Gasket for Plumbing and Sealing Needs

[Teflon Tape Gasket] is revolutionizing the way industries approach their sealing needs with its innovative Teflon tape gasket technology. The company has quickly risen to prominence in the industrial sealing industry, setting a new standard for performance and reliability.[Teflon Tape Gasket] was founded with the mission to provide high-quality sealing solutions to industries worldwide. With a focus on research and development, the company has continuously pushed the boundaries of what is possible in the field of sealing technology. Through its dedication to innovation, [Teflon Tape Gasket] has developed a range of products that have redefined industry standards.One of the key products that [Teflon Tape Gasket] has introduced to the market is its Teflon tape gasket. This revolutionary technology offers a seamless and reliable sealing solution for a wide range of industrial applications. The Teflon tape gasket is designed to provide a tight seal that is resistant to extreme temperatures, pressures, and corrosive chemicals. This makes it the ideal choice for industries such as oil and gas, chemical processing, and pharmaceuticals.The Teflon tape gasket is manufactured using the latest advancements in materials and production techniques. This ensures that each gasket meets the highest standards of quality and performance. In addition, [Teflon Tape Gasket] offers a range of customization options, allowing clients to tailor the gaskets to their specific needs.The benefits of the Teflon tape gasket are evident in its widespread adoption across various industries. Clients have reported significant improvements in operational efficiency and cost savings after implementing [Teflon Tape Gasket]'s technology. In addition, the gasket's durability and reliability have helped industries mitigate costly downtime and maintenance.In addition to its exceptional product line, [Teflon Tape Gasket] is also known for its exceptional customer service. The company works closely with clients to understand their unique sealing challenges and develop tailored solutions. This personalized approach has earned [Teflon Tape Gasket] a reputation as a trusted partner in the industry.Looking ahead, [Teflon Tape Gasket] is committed to furthering its research and development efforts to bring even more advanced sealing solutions to the market. The company's team of engineers and scientists are dedicated to pushing the boundaries of sealing technology, with a focus on sustainability and environmental responsibility.In conclusion, [Teflon Tape Gasket] has quickly established itself as a leader in the industrial sealing industry with its innovative Teflon tape gasket technology. By providing high-quality, reliable, and customizable sealing solutions, the company has earned the trust and loyalty of clients across the globe. With a commitment to ongoing innovation and customer satisfaction, [Teflon Tape Gasket] is set to continue shaping the future of industrial sealing technology.

High-Quality PTFE Dip Pipe for Industrial Applications

PTFE Dip Pipe Enhances Chemical Processing EfficiencyChemical processing industries often face challenges related to the containment and transportation of corrosive and hazardous substances. To address these challenges, [Company Name] offers a specialized solution in the form of PTFE dip pipes, which provide exceptional resistance to corrosion and high temperatures, making them ideal for a wide range of chemical applications.[Company Name] is a leading manufacturer of high-performance industrial solutions, specializing in the production of corrosion-resistant components for various industries such as chemical processing, pharmaceuticals, and petrochemicals. With a strong focus on innovation and quality, the company has gained a reputation for delivering reliable and durable products that meet the stringent requirements of modern industrial operations.The PTFE dip pipes offered by [Company Name] are designed to be used in chemical processing equipment such as reactors, tanks, and vessels, where they play a crucial role in the safe and efficient transportation of corrosive liquids and gases. The unique properties of PTFE, including its non-stick surface and resistance to chemicals, make it an ideal material for dip pipes, ensuring the integrity of the equipment and the safety of the personnel involved in the operation.One of the key advantages of PTFE dip pipes is their ability to withstand a wide range of temperatures, from cryogenic to high heat conditions, without experiencing any degradation in performance. This makes them suitable for handling a variety of chemical substances at different processing stages, contributing to the overall efficiency and productivity of the operation.Moreover, the non-stick nature of PTFE ensures that the dip pipes remain free from the build-up of deposits and contaminants, minimizing the risk of blockages and ensuring a smooth and continuous flow of materials. This not only enhances the performance of the processing equipment but also reduces the need for frequent maintenance and cleaning, leading to cost savings and improved operational uptime.The chemical resistance of PTFE dip pipes also makes them highly durable and long-lasting, even when exposed to aggressive substances such as acids, alkalis, and solvents. This reliability in the face of harsh operating conditions is essential for maintaining the safety and integrity of the chemical processing equipment, as well as meeting the regulatory standards for handling hazardous materials.Furthermore, [Company Name] offers customized solutions for PTFE dip pipes, tailored to meet the specific requirements of individual chemical processing applications. This includes the ability to design dip pipes in various lengths, diameters, and configurations, ensuring that they integrate seamlessly with the existing equipment and process requirements.In addition to their exceptional performance characteristics, PTFE dip pipes from [Company Name] are manufactured to the highest quality standards, utilizing advanced production techniques and rigorous quality control measures. This ensures that the end product meets the company's commitment to excellence and reliability, providing customers with a solution they can trust for their critical operational needs.As a responsible and customer-focused manufacturer, [Company Name] also provides comprehensive technical support and guidance to help customers select the most suitable PTFE dip pipe for their specific application. This includes expert advice on material compatibility, installation procedures, and maintenance best practices, ensuring that customers can maximize the value and performance of their investment.With the introduction of PTFE dip pipes, [Company Name] continues to demonstrate its commitment to delivering innovative and effective solutions for the chemical processing industry, offering a reliable and sustainable option for the safe and efficient handling of corrosive substances. By leveraging the unique properties of PTFE, the company is poised to make a positive impact on the operations of chemical processing facilities, helping them meet their production goals while maintaining the highest standards of safety and environmental responsibility.

High-Performance Sliding Sheet for Industrial Applications

UHMWPE Sliding Sheet Revolutionizes Industrial ApplicationsIn recent years, the industrial sector has seen significant advancements in materials and technology that have improved efficiency, durability, and safety. One such innovation is the UHMWPE (Ultra-High Molecular Weight Polyethylene) sliding sheet, which has quickly gained popularity for its impressive performance and versatility in a wide range of industrial applications.The UHMWPE sliding sheet is a high-performance industrial material that is designed to withstand extreme conditions and heavy loads. It is known for its exceptional wear resistance, low friction coefficient, and high impact strength, making it an ideal choice for applications that require smooth and reliable sliding and movement.One of the leading manufacturers of UHMWPE sliding sheets is a company that has been at the forefront of innovative materials and solutions for the industrial sector. With decades of experience and expertise in engineering high-performance materials, the company has developed a range of UHMWPE sliding sheets that have been widely adopted in various industries, including automotive, construction, and logistics.The company's UHMWPE sliding sheets are engineered to provide superior performance in demanding environments, where traditional materials often fall short. These sheets are manufactured using state-of-the-art processes and technology, resulting in a material that is exceptionally strong, durable, and reliable, even under the most challenging conditions.One of the key advantages of the company's UHMWPE sliding sheets is their ability to reduce friction and wear in industrial applications, leading to improved efficiency, reduced maintenance, and longer equipment lifespan. This has made them a popular choice for use in conveyor systems, material handling equipment, and machinery components, where smooth and reliable movement is crucial for operations.Furthermore, the UHMWPE sliding sheets offered by the company have proven to be an effective solution for reducing noise and vibration in industrial equipment, creating a more comfortable and safer working environment for operators. This has not only improved the overall productivity and performance of industrial operations but has also contributed to the well-being of workers in these environments.In addition to their performance benefits, the company's UHMWPE sliding sheets are also known for their versatility and ease of customization. They can be fabricated into various shapes, sizes, and configurations to meet the specific requirements of different applications, providing a flexible and cost-effective solution for industrial customers.The company's commitment to quality and innovation has made its UHMWPE sliding sheets a preferred choice for leading industrial companies around the world, who rely on them to enhance the performance and reliability of their equipment and operations.Looking ahead, the company continues to invest in research and development to further enhance the performance and capabilities of its UHMWPE sliding sheets, with a focus on addressing the evolving needs of the industrial sector. Through ongoing innovation and collaboration with customers, the company aims to remain a trusted partner for industrial materials and solutions, helping its customers achieve new levels of efficiency, reliability, and sustainability in their operations.In conclusion, the UHMWPE sliding sheet has become a game-changer in the industrial sector, offering unmatched performance, durability, and versatility for a wide range of applications. With a leading company at the forefront of its development and supply, industrial customers can rely on this innovative material to improve their operations and stay ahead in a competitive market.

High-quality Reagent Bottles for Laboratory Use

Simax, a renowned leader in the laboratory glassware industry, has recently launched a new and innovative reagent bottle that is set to revolutionize the way scientists and researchers work in laboratories. The company has been pushing the boundaries of laboratory glassware for over 100 years, and this latest product is a testament to their commitment to providing high-quality, reliable, and cutting-edge solutions to their customers.The new reagent bottle is manufactured using Simax's proprietary borosilicate glass, which is known for its exceptional chemical and thermal resistance. This makes the bottle suitable for a wide range of applications, from storing and mixing reagents to carrying out chemical reactions. The material also ensures that the bottle is highly durable and able to withstand harsh laboratory conditions, making it a long-lasting and cost-effective investment for any laboratory.In addition to its robust construction, the reagent bottle features a range of innovative design elements that set it apart from traditional glassware. For example, the bottle is equipped with a specially designed cap that provides a secure seal, preventing any leakage or contamination of the contents. This is particularly important in laboratory settings where accuracy and precision are paramount.Furthermore, the reagent bottle is available in a variety of sizes, allowing scientists and researchers to choose the most suitable option for their specific needs. This flexibility makes the bottle an ideal solution for a wide range of applications, from academic research to industrial testing.Simax's commitment to quality and innovation is also evident in their rigorous testing and quality control processes. Each reagent bottle undergoes a series of stringent tests to ensure that it meets the highest standards of performance and safety. This dedication to quality gives customers peace of mind, knowing that they can rely on Simax's products for their critical laboratory work.The launch of the new reagent bottle is part of Simax's broader mission to continually push the boundaries of what is possible in the laboratory glassware industry. By combining their extensive expertise with cutting-edge technology and materials, the company is able to deliver products that meet the evolving needs of their customers.Simax's commitment to sustainability is also reflected in the reagent bottle, as the company has taken significant steps to reduce its environmental impact. The bottle is fully recyclable, reducing the overall waste generated in laboratories. Furthermore, the durability of the bottle means that it has a long lifespan, further reducing the need for frequent replacements.Overall, the new reagent bottle from Simax represents a significant advancement in laboratory glassware technology. Its combination of durability, reliability, and innovative design ensures that it will serve as an invaluable tool for scientists and researchers across various industries. With Simax's long-standing reputation for excellence and their commitment to quality, the reagent bottle is set to become a staple in laboratories around the world.