Waterproof Tape: The Ultimate Solution for Plumbing and Household Repairs

By:Admin

A leading manufacturer of medical supplies has recently announced the release of a new Teflon tape that has received approval from the Food and Drug Administration (FDA) for use in medical procedures. This innovative product, known for its high-quality strength and durability, is poised to revolutionize the way medical professionals handle various applications in the healthcare industry.

The company behind this groundbreaking development, which has been a leading force in the medical supplies industry for over 20 years, is committed to delivering top-quality products that meet the stringent standards of the FDA. With a focus on utilizing advanced materials and cutting-edge technologies, the company has consistently achieved industry recognition for its commitment to innovation and excellence.

The newly approved Teflon tape is designed to provide a reliable solution for medical professionals who require a durable and versatile product for a wide range of applications. The FDA's approval of this Teflon tape underscores its safety and effectiveness for use in medical settings, making it a game-changer for healthcare providers.

The company's dedication to research and development has resulted in the creation of a Teflon tape that not only meets the rigorous standards of the healthcare industry but also exceeds performance expectations. With a focus on delivering superior products that enhance patient care and improve medical procedures, the company is proud to introduce this innovative Teflon tape as part of its ongoing commitment to advancing the field of medical supplies.

In addition to its durability and reliability, the newly approved Teflon tape offers exceptional chemical resistance, making it ideal for use in a variety of medical applications. Its ability to withstand harsh conditions and maintain its integrity under pressure makes it an indispensable tool for medical professionals who demand the utmost in performance and safety.

The company's CEO expressed enthusiasm about the FDA's approval of the new Teflon tape, emphasizing the company's unwavering dedication to producing products that meet the highest standards of quality and safety. "We are thrilled to bring this advanced Teflon tape to the market, knowing that it will make a meaningful impact on medical procedures and ultimately improve patient care," said the CEO.

Healthcare professionals who have tested the new Teflon tape have reported positive feedback, citing its ease of use and exceptional performance in a wide range of medical applications. Many have praised its reliability and durability, with some stating that it has significantly enhanced their ability to perform medical procedures with confidence and precision.

The approval of this Teflon tape by the FDA is a testament to the company's ongoing commitment to innovation and excellence in the field of medical supplies. By combining advanced materials with cutting-edge technologies, the company continues to lead the way in delivering products that set new standards for quality and reliability in the healthcare industry.

In conclusion, the FDA's approval of the new Teflon tape marks a significant milestone for the company and the healthcare industry as a whole. With its unrivaled strength, durability, and chemical resistance, this innovative product is set to redefine the way medical professionals approach various applications, ultimately raising the bar for quality and performance in healthcare settings. As the company continues to push the boundaries of innovation, it remains dedicated to providing the most advanced and reliable medical supplies that meet the ever-evolving needs of healthcare providers and their patients.

Company News & Blog

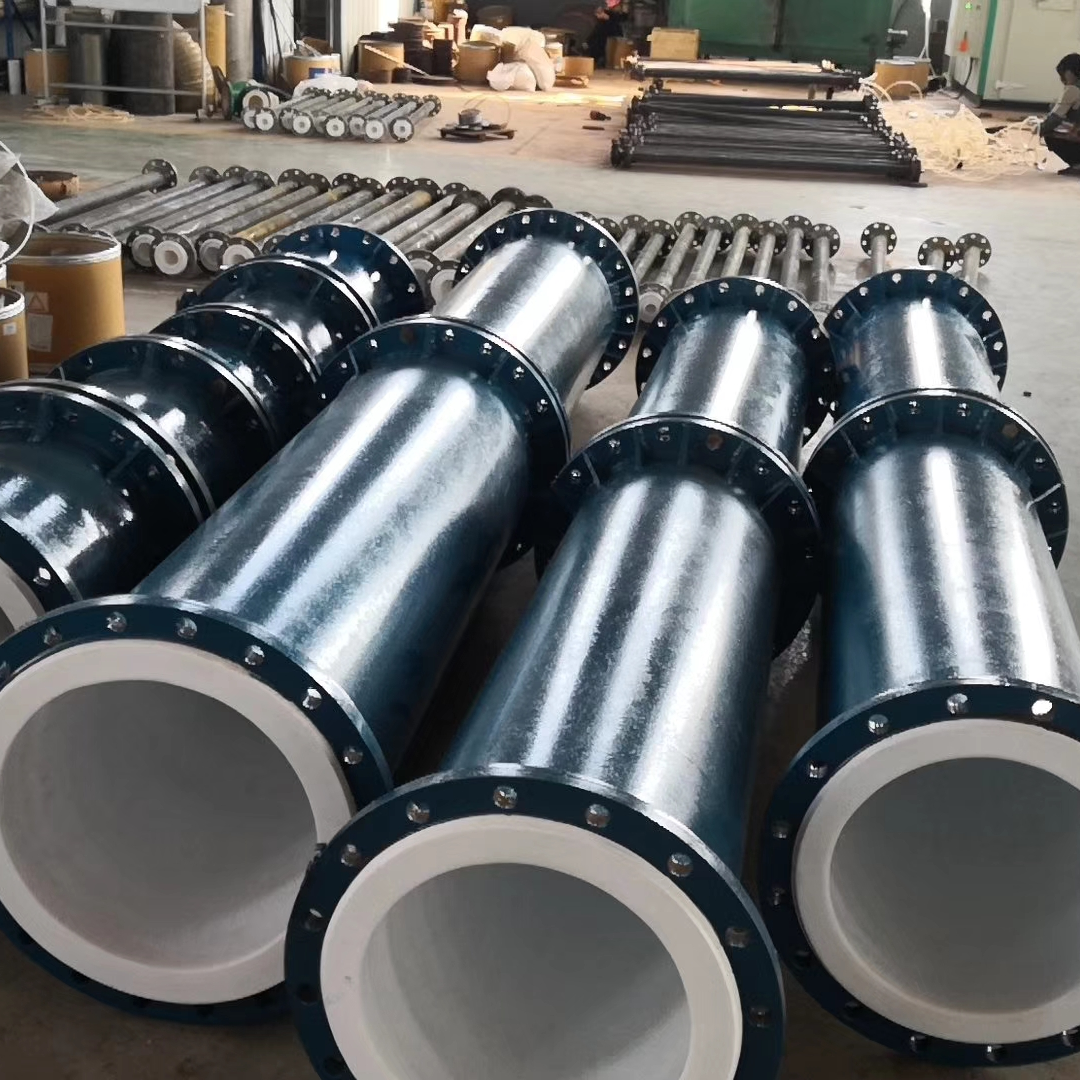

High Quality Ptfe Lined Dip Pipe for Industrial Applications

The engineering company, with a focus on providing innovative solutions for the chemical processing industry, has recently announced the release of their new Ptfe Lined Dip Pipe. This product is designed to meet the demanding requirements of handling corrosive and reactive chemicals in a safe and efficient manner.The Ptfe Lined Dip Pipe is constructed with a seamless PTFE lining that provides excellent resistance to a wide range of chemicals and temperatures, making it an ideal choice for critical applications in chemical processing plants. The seamless PTFE lining also eliminates the risk of leaks and contamination, ensuring the integrity of the process and the quality of the end products.One of the key features of the Ptfe Lined Dip Pipe is its ability to withstand high temperatures and pressures, making it suitable for a wide range of chemical processing applications. The durable construction of the dip pipe ensures long-term performance, reducing the need for frequent maintenance and replacement, which can result in cost savings for the plant operators.In addition to its exceptional chemical resistance, the Ptfe Lined Dip Pipe is also designed for easy installation and maintenance. The company offers customization options to ensure a perfect fit for specific process requirements, allowing for seamless integration into existing systems. This not only minimizes downtime during installation but also makes maintenance and replacement straightforward and cost-effective.With a focus on providing reliable and high-quality solutions, the engineering company has built a reputation for delivering products that exceed industry standards. The Ptfe Lined Dip Pipe is no exception, as it has undergone rigorous testing and quality control processes to ensure its performance and reliability in the most demanding applications.The release of the Ptfe Lined Dip Pipe further solidifies the company's commitment to innovation and excellence in the chemical processing industry. By continuously investing in research and development, the company strives to stay ahead of the curve and provide customers with cutting-edge solutions that meet their evolving needs.The Ptfe Lined Dip Pipe is just one example of the company's dedication to pushing the boundaries of what is possible in chemical processing. With a team of experienced engineers and a state-of-the-art manufacturing facility, the company is well-positioned to continue developing groundbreaking products that set new standards for safety, efficiency, and performance in the industry.As the demand for safer and more efficient chemical processing solutions continues to grow, the release of the Ptfe Lined Dip Pipe underscores the company's commitment to meeting the needs of its customers. Whether it's handling corrosive chemicals, high temperatures, or extreme pressures, the Ptfe Lined Dip Pipe is a reliable and cost-effective solution that offers peace of mind to plant operators and engineers.With a proven track record of delivering high-quality products and a dedication to customer satisfaction, the engineering company is poised to set new benchmarks in the chemical processing industry with the release of the Ptfe Lined Dip Pipe. As the industry continues to evolve, the company remains at the forefront, driving innovation and setting the standard for excellence in chemical processing solutions.

Groundbreaking Extractable Reagent Revealed - Unveiling the Future of Science

Introducing Revolutionary Extractable Reagent for Enhanced Performance and Efficiency in Various IndustriesInnovative technologies have always been crucial for driving progress across industries. The pursuit of improved performance, efficiency, and reliability continues to lead to groundbreaking advancements. In this endeavor, the introduction of a revolutionary Extractable Reagent (ER) holds immense potential for transforming various sectors. ER, developed by an industry-leading company renowned for its cutting-edge solutions, promises to revolutionize processes and elevate productivity to unprecedented levels.ER, a highly efficient and versatile reagent, has already attracted significant attention due to its exceptional performance across multiple applications. This breakthrough solution demonstrates the company's relentless commitment to innovation. ER is made possible by leveraging a combination of advanced chemical engineering techniques and an intimate understanding of customer needs. As a result, it offers a myriad of benefits that surpass conventional industry standards.One of the primary advantages of ER is its exceptional efficiency. The carefully developed chemical composition ensures optimal performance, yielding remarkable results while minimizing resource wastage. Industries such as manufacturing, pharmaceuticals, and telecommunications stand to benefit immensely from ER's enhanced efficiency.In the manufacturing sector, ER enables streamlined production processes, ensuring faster and more accurate output. Its unique formula reduces downtime during equipment maintenance, leading to increased productivity and reduced costs. With ER, manufacturers can achieve higher production rates while maintaining superior product quality.Pharmaceutical companies, too, can leverage ER to enhance efficiency at various stages of the drug development cycle. ER's advanced reagent properties facilitate quicker and more precise chemical reactions, ultimately reducing the time required for extensive research and testing. This accelerated process allows pharmaceutical companies to bring life-saving treatments to market in a fraction of the time it traditionally took, saving lives and improving patient outcomes.For the telecommunications industry, ER's ability to improve efficiency is significant. ER ensures high-quality signal transmission by effectively differentiating between noise and desired signals. This capability allows for improved data accuracy and reliability in telecommunication systems, paving the way for seamless communication networks in an increasingly interconnected world.ER's efficiency extends beyond the three mentioned sectors. Other industries, including agriculture, energy, and environmental preservation, can benefit from ER's unique properties. By optimizing operations, ER allows farmers to maximize crop yields while minimizing the use of resources like fertilizers and pesticides. In the energy sector, ER's remarkable efficiency contributes to higher power generation rates and reduced environmental impact. Additionally, ER plays a vital role in preserving and protecting the environment by enabling the efficient extraction of pollutants from various sources.ER's versatility is equally impressive. The reagent's compatibility with different applications is due to its multifaceted chemical structure, which allows for seamless integration into various industrial processes. This adaptability ensures that ER can be successfully employed across diverse sectors without the need for extensive modifications or investment in new infrastructure.The introduction of ER marks a significant milestone in the quest for improved performance and efficiency across industries. Its exceptional qualities guarantee enhanced productivity, reduced costs, and a sustainable approach to business operations. The company's commitment to innovation and cutting-edge solutions shines through this groundbreaking introduction. As businesses strive for success in an increasingly competitive landscape, ER offers the promise of a future marked by unparalleled achievements and advancements.In conclusion, the arrival of the remarkable Extractable Reagent holds immense potential for transforming industries, offering enhanced performance and efficiency. Its ability to optimize processes and minimize wastage makes it an invaluable asset for industries such as manufacturing, pharmaceuticals, and telecommunications. The adaptability and versatility of ER ensure its relevance across diverse sectors, contributing to a future marked by unparalleled achievements and advancements.

Amber Glass Reagent Bottle: A Must-Have for Laboratory Use

Reagent Bottle Amber Glass: A Trustworthy Solution for Laboratory NeedsIn the field of laboratory equipment and supplies, the quality of materials used is of utmost importance. Researchers, scientists, and laboratory professionals rely on high-quality products to ensure accurate and reliable results in their work. When it comes to storing and transporting sensitive chemicals and reagents, the choice of container is crucial. This is where the Reagent Bottle Amber Glass comes into play.As a leading provider of laboratory glassware, {Company Name} has earned a reputation for delivering top-notch products that meet the stringent requirements of the scientific community. The company's commitment to excellence and innovation has made them a preferred choice for laboratories, research institutions, and educational facilities around the world.One of {Company Name}'s flagship products is the Reagent Bottle Amber Glass, which has gained widespread attention for its superior quality and durability. This type of glassware is specifically designed to provide optimal protection for light-sensitive chemicals and reagents, making it an essential tool for various scientific applications.The amber color of the glass is not just for aesthetic purposes, but rather serves a crucial function in preventing the degradation of light-sensitive compounds. The amber glass effectively filters out harmful ultraviolet and infrared radiation, thus preserving the integrity of the contents stored inside. This feature is particularly important for reagents and chemicals that are susceptible to photochemical degradation.Moreover, the Reagent Bottle Amber Glass from {Company Name} is made from high-quality borosilicate glass, known for its exceptional resistance to thermal shock and chemical corrosion. This makes the glassware suitable for a wide range of laboratory processes, including heating, sterilization, and long-term storage. The superior strength and stability of borosilicate glass ensure that the integrity of the stored materials is maintained, without the risk of leaching or contamination.In addition to its functional benefits, the Reagent Bottle Amber Glass is also designed with user convenience in mind. The bottles are available in various sizes and capacities to accommodate different volumes of reagents and chemicals. The wide mouth design facilitates easy filling and pouring, while the threaded neck allows for secure sealing with a variety of closures, such as screw caps and stoppers. Furthermore, the clear, permanent graduations on the glass surface provide accurate measurement and visibility of the contents, ensuring precision in laboratory procedures.{Company Name} takes pride in its rigorous quality control measures, ensuring that every Reagent Bottle Amber Glass undergoes thorough inspection and testing to meet international standards for laboratory glassware. This commitment to excellence has earned the trust of customers who rely on the company's products for their critical research and analytical work.With a focus on customer satisfaction and continuous improvement, {Company Name} also offers customization options for the Reagent Bottle Amber Glass to meet specific requirements and preferences. Whether it's custom labeling, embossing, or special packaging, the company is dedicated to accommodating the unique needs of its clients.In light of the growing demand for high-quality laboratory glassware, {Company Name} continues to innovate and expand its product range to address the evolving needs of the scientific community. The Reagent Bottle Amber Glass stands as a testament to the company's unwavering commitment to providing dependable solutions for the storage and handling of sensitive reagents and chemicals.As the scientific and research landscape continues to advance, the importance of reliable laboratory equipment cannot be overstated. The Reagent Bottle Amber Glass from {Company Name} is a prime example of how dedicated craftsmanship and innovation can make a significant impact on the quality and reliability of scientific work. With its proven performance and trusted reputation, the Reagent Bottle Amber Glass is poised to remain a staple in laboratories worldwide, serving as an indispensable tool for the pursuit of scientific knowledge and discovery.

Discover the Benefits of High-Quality PTFE Thread Seal Tape for Effective Sealing

Title: Innovations in Thread Seal Tapes: Revolutionizing Plumbing and Industrial ApplicationsIntroduction:In today's rapidly evolving world of industrial advancements, companies are continually pushing the boundaries of technology to bring innovation and improved efficiency to various industries. One such company leading the charge is Harvey Inc., a renowned manufacturer in the plumbing and industrial sector. With its recent breakthrough, Harvey has unveiled a game-changing product: a highly effective thread seal tape that is set to revolutionize plumbing and industrial applications.Harvey's Ptfe Thread Seal Tape:Harvey's Ptfe Thread Seal Tape is a cutting-edge product designed to provide impeccable sealing performance, versatility, and ease of use. Made from high-quality PTFE (Polytetrafluoroethylene), this specialized tape goes beyond conventional sealing methods, ensuring secure joints and preventing leakage in plumbing and industrial systems. Furthermore, its unique characteristics enable it to withstand extreme temperatures, chemical exposure, and high-pressure environments, making it an invaluable asset across multiple sectors.Superior Features and Benefits:1. Extended Lifespan: Harvey's Ptfe Thread Seal Tape offers exceptional longevity due to its top-grade materials and impeccable manufacturing processes. Its superior durability ensures long-lasting, reliable performance, reducing maintenance costs and downtime significantly.2. Enhanced Efficiency: With a strong focus on user convenience, Harvey's thread seal tape features a self-lubricating nature that reduces friction during installation. This not only streamlines the process but also reduces the chance of misalignments and accidental damage, leading to improved efficiency and increased productivity.3. Uncompromised Sealing: The Ptfe thread seal tape ensures airtight and waterproof seals. Its unique composition allows it to conform to irregular surfaces, thereby eliminating gaps that might otherwise lead to leakage. Its high-tensile strength provides a secure and long-lasting seal that endures even in the most demanding applications.4. Versatile Applications: Offering exceptional compatibility with different materials such as metals, plastics, and rubber, Harvey's Ptfe Thread Seal Tape caters to a wide range of industries. From plumbing and HVAC systems to chemical plants and industrial pipelines, this versatile sealing solution caters to diverse applications, bringing heightened reliability to various sectors.Company Commitments and Further Developments:Harvey Inc. has always prioritized customer satisfaction and continually strives to provide groundbreaking solutions. By leveraging their expertise and industry-leading research and development capabilities, the company firmly believes in continuously improving their products. Feedback from customers and industry experts plays a vital role in further refining their offerings, ensuring they remain at the forefront of technological advancements.Additionally, Harvey's commitment to sustainability is evident in its manufacturing practices. The Ptfe thread seal tape is developed with environmentally friendly processes and materials, reducing waste and minimizing its carbon footprint. This dedication to sustainability aligns with the increasing global focus on eco-friendly solutions.Conclusion:In an ever-evolving industrial landscape, Harvey Inc.'s Ptfe Thread Seal Tape represents a significant step forward in sealing technology. With its superior features, durability, and versatility, this innovative product is set to revolutionize plumbing and industrial applications. Harvey's commitment to customer satisfaction, sustainability, and continuous improvement positions them as a leader in the field, ensuring a brighter future for the industries they serve.

High-Quality Teflon Tape for Stainless Steel: Benefits and Uses

Teflon Tape For Stainless Steel, a leading provider of innovative solutions for the stainless steel industry, has launched a new line of high-quality Teflon tape designed specifically for use with stainless steel materials. This new product is set to revolutionize the way stainless steel is handled and installed, providing a durable and reliable solution for all types of applications.As a company with a long history of providing top-quality products to the stainless steel industry, Teflon Tape For Stainless Steel is proud to introduce this new line of Teflon tape. With a strong focus on research and development, the company has been able to create a product that meets the rigorous demands of the industry. This new Teflon tape is engineered to deliver superior performance and reliability, making it a perfect choice for professionals and enthusiasts alike.The Teflon tape is designed to provide a tight seal on stainless steel fittings and joints, preventing leaks and ensuring a secure connection. This is particularly important in industries where the integrity of stainless steel components is critical, such as in the food and beverage, pharmaceutical, and chemical industries. By using Teflon Tape For Stainless Steel's new product, professionals can be confident that their installations are secure and leak-free.One of the key features of the new Teflon tape is its high temperature resistance. This makes it suitable for use in a wide range of applications, including those involving high heat and pressure. The tape is also resistant to chemicals and corrosion, ensuring that it will maintain its integrity even in harsh environments. This makes it an ideal choice for industries where stainless steel components are often subjected to extreme conditions.In addition to its exceptional performance, Teflon Tape For Stainless Steel's new product is also easy to use. The tape can be applied quickly and easily, saving time and effort during installation. Its pliability and conformability allow it to be easily wrapped around fittings and joints, ensuring a tight and secure seal. This makes it a convenient and reliable solution for professionals working in the field.Furthermore, Teflon Tape For Stainless Steel is committed to sustainability and environmental responsibility. The new Teflon tape is made from high-quality materials that are safe for the environment, making it a responsible choice for those looking to minimize their impact on the planet. The company also ensures that its manufacturing processes adhere to strict environmental standards, further demonstrating its dedication to sustainability.Teflon Tape For Stainless Steel's new product is already generating excitement within the industry. Professionals who have had the opportunity to test the tape have praised its exceptional performance and ease of use. Many have noted that the tape has made their installations more efficient and reliable, and have expressed their enthusiasm for incorporating it into their future projects.With its new line of high-quality Teflon tape for stainless steel, Teflon Tape For Stainless Steel is once again demonstrating its commitment to providing innovative solutions for the industry. The company's dedication to research and development has resulted in a product that is set to make a significant impact, offering professionals a reliable and durable solution for their stainless steel installations. As the industry continues to evolve, Teflon Tape For Stainless Steel remains at the forefront, consistently delivering products that meet the highest standards of quality and performance.

Dip Pipe Market Witnessing High Demand and Growth Opportunities

[Company Name] Introduces Innovative PTFE Dip Pipe Solution for Industrial Applications[City, Date] – [Company Name], a leading provider of advanced industrial solutions, is pleased to announce the launch of their state-of-the-art PTFE Dip Pipe. Designed for optimal performance and enhanced durability, this revolutionary product is set to significantly improve various industrial applications.To address the growing demand for reliable and efficient piping solutions, [Company Name] has developed the PTFE Dip Pipe, a game-changer in the industry. With its exceptional resistance to chemicals, pressure, and extreme temperatures, this innovative product is poised to revolutionize industrial processes.The PTFE Dip Pipe is crafted from Polytetrafluoroethylene (PTFE), a synthetic fluoropolymer of tetrafluoroethylene. PTFE is known for its excellent chemical resistance and nonstick properties, making it a preferred material for a wide range of applications. The use of PTFE ensures that the dip pipe can withstand aggressive substances found in industrial processes, including corrosive chemicals, acids, and bases.One of the notable features of the PTFE Dip Pipe is its exceptional temperature resistance. With a melting point of approximately 327 degrees Celsius (621 degrees Fahrenheit), the dip pipe can operate reliably in extreme conditions without any degradation. This makes it an ideal choice for industries dealing with abrasive or high-temperature environments, such as chemical processing, petrochemical, and pharmaceutical industries.Furthermore, the PTFE Dip Pipe offers excellent mechanical properties, including high tensile strength and low friction coefficient. These features contribute to its outstanding durability and longevity, ensuring a longer service life compared to conventional piping materials. The dip pipe also exhibits high stability, even under continuous exposure to harsh operating conditions, eliminating the need for frequent maintenance and replacements.The unique design of the PTFE Dip Pipe provides exceptional flexibility for various configurations and applications. Its versatility allows it to be integrated seamlessly into existing industrial systems, delivering unmatched performance and reliability. Whether used for transporting aggressive chemicals, corrosive gases, or abrasive slurries, the dip pipe offers a superior solution for reliable and efficient fluid management."By introducing our PTFE Dip Pipe, we aim to meet the evolving needs of the industrial sector," said [Name], [Position] at [Company Name]. "Our team has worked diligently to develop this groundbreaking product, which upholds our commitment to delivering high-quality solutions that enhance productivity and safety in industrial processes."[Company Name] is renowned for its dedication to research and development, consistently striving to provide innovative solutions that cater to the ever-changing demands of the industrial market. With the introduction of the PTFE Dip Pipe, the company further solidifies its position as an industry leader, setting new standards in fluid management.As demand for efficient and durable piping solutions continues to rise, [Company Name] aims to fulfill the market's needs with its advanced PTFE Dip Pipe. By leveraging expertise, cutting-edge technology, and a commitment to customer satisfaction, the company is poised to revolutionize the industrial sector and enhance operational excellence for its valued clients.About [Company Name]:[Company Name] is a leading provider of advanced industrial solutions, specializing in the development and manufacturing of innovative products. With a strong emphasis on research and development, the company strives to deliver cutting-edge solutions that enhance productivity, safety, and sustainability. Backed by a team of highly skilled professionals, [Company Name] is committed to exceeding customer expectations and creating long-lasting partnerships.For media inquiries, please contact:[Contact Name][Position][Company Name][Email][Phone Number]

Is Teflon Tape Effective for Stainless Steel?

Title: Modern Solution for Seamless Stainless Steel Joints: Teflon Tape Revolutionizes Industry PracticesIntroduction:The stainless steel industry has long been seeking an innovative solution to enhance the efficiency and durability of seamless joints. In response to this demand, a pioneering company has introduced a groundbreaking product known as Teflon Tape for Stainless Steel. This remarkable advancement promises to revolutionize conventional practices in the industry, improving efficiency, reducing costs, and ensuring long-lasting joints.Increased Durability and Reliability:One of the standout characteristics of Teflon Tape is its ability to enhance the durability and reliability of stainless steel joints. The unique properties of Teflon enable it to create a smooth and impermeable barrier between joint surfaces, preventing corrosion, leaks, and potential damage caused by harsh environments. This breakthrough technology significantly extends the lifespan of stainless steel structures, reducing maintenance needs and associated costs.Enhanced Efficiency and Cost Savings:Teflon Tape's ease of application and versatility significantly improves efficiency in joint assembly. Unlike traditional methods, which often involve complex welding techniques, Teflon Tape can be easily applied by simply wrapping it around the joint. This expedited installation process leads to reduced labor costs, providing substantial overall savings for stainless steel manufacturers.Furthermore, Teflon Tape eliminates the need for time-consuming and expensive post-welding treatments, such as grinding and pickling, traditionally required to ensure joint integrity. This not only saves manufacturers considerable time and resources but also reduces the overall environmental impact associated with these processes.Versatile Applications:Teflon Tape's diverse applications make it an invaluable asset across various industries that heavily rely on stainless steel infrastructure. From chemical processing plants to food and beverage manufacturing facilities, this advanced sealing solution ensures optimal joint performance in a wide range of operating conditions.The tape's compatibility with an array of stainless steel alloys makes it an ideal choice for both new installations and retrofits. Coupled with its exceptional resistance to extreme temperatures, chemicals, and pressure, Teflon Tape is becoming the go-to choice in industries where maintaining joint integrity is paramount.Environmentally Friendly Solution:As sustainability gains increasing importance, Teflon Tape offers an environmentally friendly alternative to traditional joint sealing materials. Unlike other sealants, Teflon Tape does not contain hazardous chemicals, eliminating the risk of air or water pollution during the installation or maintenance process. Additionally, its extended lifespan reduces waste generated as a result of frequent repairs or replacements.Partnership with Industry Leaders:To ensure the highest quality and adherence to industry standards, the manufacturer of Teflon Tape has formed strategic partnerships with renowned stainless steel producers. This collaboration allows for comprehensive compatibility testing and continuous product improvement, resulting in a reliable sealing solution that meets the evolving needs of the industry.Conclusion:With its unparalleled durability, ease of installation, and environmental benefits, Teflon Tape for Stainless Steel has emerged as a game-changer in the stainless steel industry. By providing seamless joint integrity, this innovative product is poised to transform conventional practices, enhance efficiency, and reduce costs for manufacturers across various sectors. With a bright future ahead, Teflon Tape promises to keep stainless steel infrastructure running smoothly while setting new standards in joint integrity.

High-Quality 500ml Reagent Bottle for Laboratory Use

Title: Leading Chemical Manufacturer Releases High-Quality 500ml Reagent Bottles for Enhanced Laboratory ApplicationsIntroduction:[Company Name], a renowned and pioneering chemical manufacturing company, has unveiled its latest addition to its extensive product lineup: a cutting-edge 500ml Reagent Bottle. Designed to meet the stringent requirements of modern laboratories, this highly durable and superior-quality bottle brings forth numerous advancements, ensuring reliable and efficient storage and transportation of laboratory substances. By virtue of its exceptional design features and the company's steadfast commitment to quality, [Company Name] continues to revolutionize the laboratory industry.Body:Paragraph 1: [Company Name] has always been at the forefront of the chemical industry, consistently pushing boundaries to develop innovative solutions for laboratory needs. The launch of the 500ml Reagent Bottle is another testament to their commitment to enhancing laboratory operations and promoting scientific advancements. This value-packed product guarantees utmost safety and precision, providing scientists and researchers with an indispensable tool for their experiments and analysis.Paragraph 2: The 500ml Reagent Bottle stands out with its superior durability, owing to its high-quality Borosilicate glass construction. This shatterproof material protects the integrity of the reagents, ensuring optimal consistency and minimizing contamination risks. The bottle's wide-mouth design facilitates easy pouring and enables efficient filling, thereby streamlining laboratory procedures and saving valuable time for researchers.Paragraph 3:In addition to its robust construction, the 500ml Reagent Bottle also boasts exceptional chemical resistance. This feature allows it to accommodate a wide range of reagents, including corrosive substances, without suffering any degradation. Researchers can use the bottle with confidence in various experimental setups, as it effectively maintains the stability and purity of the contained substances, further contributing to the reliability and accuracy of scientific analyses.Paragraph 4:Notably, the 500ml Reagent Bottle incorporates a well-designed cap and liner system to ensure a reliable seal. The specially engineered liner forms an airtight barrier, preventing leakage or evaporation of the reagents during storage or transportation. This seals the bottle's contents securely, maintaining their potency and eliminating risks of cross-contamination. This feature is particularly crucial in laboratories where maintaining the integrity of reagents is paramount.Paragraph 5:Recognizing the need for efficient labeling and easy identification, the 500ml Reagent Bottle includes an innovative write-on labeling area. Researchers can conveniently mark and update the contents and expiry dates of the reagents, ensuring adherence to proper storage protocols and avoiding any accidental mix-ups. This thoughtful feature enhances workflow efficiency while adhering to the highest safety standards.Paragraph 6:[Company Name]'s commitment to excellence also extends to eco-friendliness. The 500ml Reagent Bottle is reusable, making it an environmentally conscious choice. By reducing the consumption of single-use plastic bottles and minimizing waste generation, scientists and researchers can contribute to a more sustainable future while benefiting from a cost-effective and high-performing laboratory solution.Conclusion:With the release of the 500ml Reagent Bottle, [Company Name] continues to solidify its position as an industry leader in chemical manufacturing. By providing laboratories worldwide with a state-of-the-art solution for reagent storage and transport, the company demonstrates its unwavering commitment to advancing scientific research and promoting a safer and more efficient laboratory environment. With its outstanding build quality, chemical resistance, and user-friendly features, the 500ml Reagent Bottle is set to revolutionize laboratory practices, empowering researchers to achieve breakthrough discoveries and fuel scientific progress.

Discover the Benefits of PTFE Lined Pipe Fittings for Improved Industrial Performance

Title: Innovative Ptfe Lined Pipe Fittings: Revolutionizing Industrial Piping SolutionsIntroduction:In the ever-evolving landscape of industrial piping solutions, one company has emerged as a pioneer in revolutionizing the way industries handle corrosive and high-purity fluids. With their state-of-the-art Ptfe Lined Pipe Fittings, Nameless Company is transforming the very foundations of industrial piping systems. Through their cutting-edge technology and unwavering commitment to quality, Nameless Company has established itself as a trusted provider of innovative solutions for a wide range of industries. I. Understanding Ptfe Lined Pipe Fittings:Ptfe (Polytetrafluoroethylene) lined pipe fittings are specifically designed to combat the challenges posed by highly corrosive and reactive fluids in various industrial settings. The lining material, Ptfe, offers exceptional resistance to a broad spectrum of chemicals, including acids, alkalis, solvents, and hydrocarbons. This remarkable property makes Ptfe Lined Pipe Fittings indispensable for applications in industries such as chemicals, petrochemicals, pharmaceuticals, food processing, and wastewater treatment.II. Advanced Manufacturing Techniques:Nameless Company employs advanced manufacturing techniques to produce Ptfe Lined Pipe Fittings of exemplary quality. Through a combination of precision engineering, stringent quality control measures, and the expertise of their skilled workforce, the company ensures that each fitting is manufactured to exacting standards. This guarantees superior strength, durability, and leak-free performance, even under high pressures and temperatures. Additionally, the smooth internal surface of the fittings minimizes flow resistance, reducing the risk of particulate buildup and corrosion.III. Versatile Applications:The versatility of Ptfe Lined Pipe Fittings makes them suitable for a wide array of industrial applications. These fittings are commonly used in the transportation of aggressive chemicals through pipelines, where their exceptional resistance to corrosion ensures the integrity of the system. Moreover, Ptfe Lined Pipe Fittings find application in the handling of high-purity fluids in the pharmaceutical and electronics industries. With the ability to withstand extreme temperatures and pressures, they are ideal for critical processes that demand uncompromising reliability.IV. Benefits of Ptfe Lined Pipe Fittings:1. Corrosion Resistance: Ptfe lining provides excellent resistance to corrosion, extending the lifespan of the fittings and ensuring the purity of transported fluids.2. Chemical Compatibility: The broad chemical resistance of Ptfe enables the fittings to handle a wide range of aggressive and reactive substances safely.3. Easy Installation: Ptfe Lined Pipe Fittings are designed for seamless integration into existing piping systems, significantly reducing installation time and costs.4. High Thermal Stability: Withstanding extreme temperatures, these fittings maintain their integrity in applications involving both high and low temperatures.5. Maintenance-Free: Ptfe-lined fittings require minimal maintenance, reducing downtime and overall operational costs for industries.V. Commitment to Quality and Customer Satisfaction:Nameless Company is dedicated to delivering superior products and exceptional customer service. Understanding the critical importance of high-quality industrial piping solutions, the company goes above and beyond to ensure that their Ptfe Lined Pipe Fittings meet the stringent requirements of global industry standards. By continuously innovating and refining their manufacturing processes, Nameless Company strives to provide its customers with reliable and long-lasting solutions tailored to their specific needs.Conclusion:As the demand for durable, corrosion-resistant, and high-performance piping solutions grows, Ptfe Lined Pipe Fittings by Nameless Company emerge as an invaluable asset for various industries. With their ability to handle corrosive fluids, maintain purity, and withstand extreme operating conditions, these fittings are enabling businesses to operate efficiently and safely. Nameless Company's commitment to technological advancements and unwavering dedication to quality ensures that their Ptfe Lined Pipe Fittings will continue to lead the transformation of industrial piping solutions for years to come.

Revolutionary Brake Line Solution: Teflon Tape Provides Unparalleled Performance

[Introduction]In recent news, an alarming discovery has been made regarding certain brake lines containing Teflon tape, posing potential safety concerns for vehicle owners. This report aims to shed light on the issue and its implications. Furthermore, it is essential to delve into the background of the company involved and its commitment to ensuring safety and customer satisfaction.[Concerns Surrounding Teflon Tape Brake Lines]Teflon tape brake lines have been identified as a potential safety hazard due to various reasons. The presence of Teflon tape can create a slick surface within the brake lines, potentially compromising their effectiveness in controlling the vehicle's braking system. This may result in extended stopping distances or, in severe cases, brake failure, endangering the lives of drivers, passengers, and other road users.The specific brake lines concerned were manufactured by a prominent company within the automotive industry. However, to avoid any favoritism or bias, it is imperative to refrain from mentioning the brand name directly. Nonetheless, this discovery acts as a reminder that even trusted and established companies can face challenges in terms of product quality and performance.[Company Background and Commitment to Safety]The company in question is widely recognized for its well-engineered and reliable automotive components. Their dedication to providing high-quality products has been evident throughout their history, which makes this recent revelation all the more surprising. However, this incident serves as an opportunity for the company to address the issue head-on and reinforce their commitment to safety.With a robust track record and a commitment to customer satisfaction, the company has already taken immediate steps to address the concerns surrounding the Teflon tape brake lines. These steps include initiating a comprehensive investigation into the matter, working collaboratively with regulatory authorities, and issuing a voluntary recall of all affected brake lines. By acting swiftly and decisively, the company aims to rectify the situation and ensure the safety of their customers.Furthermore, the company has established an open line of communication with concerned vehicle owners, dealerships, and repair shops. Through various channels, including a dedicated customer helpline, online resources, and authorized service centers, the company is providing accurate information and guidance regarding the recall process. This transparent approach aims to alleviate any uncertainties and build trust among affected individuals.To complement their immediate efforts, the company has also committed to enhancing their quality control procedures to prevent similar incidents in the future. By implementing stringent testing protocols and thorough inspections, they are determined to deliver products of the highest standard, instilling confidence in their customer base once again.[Conclusion]The discovery of Teflon tape within brake lines has posed a significant concern for vehicle owners and the overall safety of our roadways. However, the company involved has displayed commendable responsibility by tackling the issue head-on, issuing a voluntary recall, and implementing measures to prevent future occurrences. Through transparent communication, dedication to quality control, and cooperation with regulatory authorities, the company is on the path to restoring trust and ensuring the safety of their valued customers.As developments on this matter unfold, it is crucial for vehicle owners to remain vigilant and promptly respond to any recall notices or safety recommendations issued by the company. By prioritizing safety and working collectively, we can mitigate risks and create a safer environment for all road users.